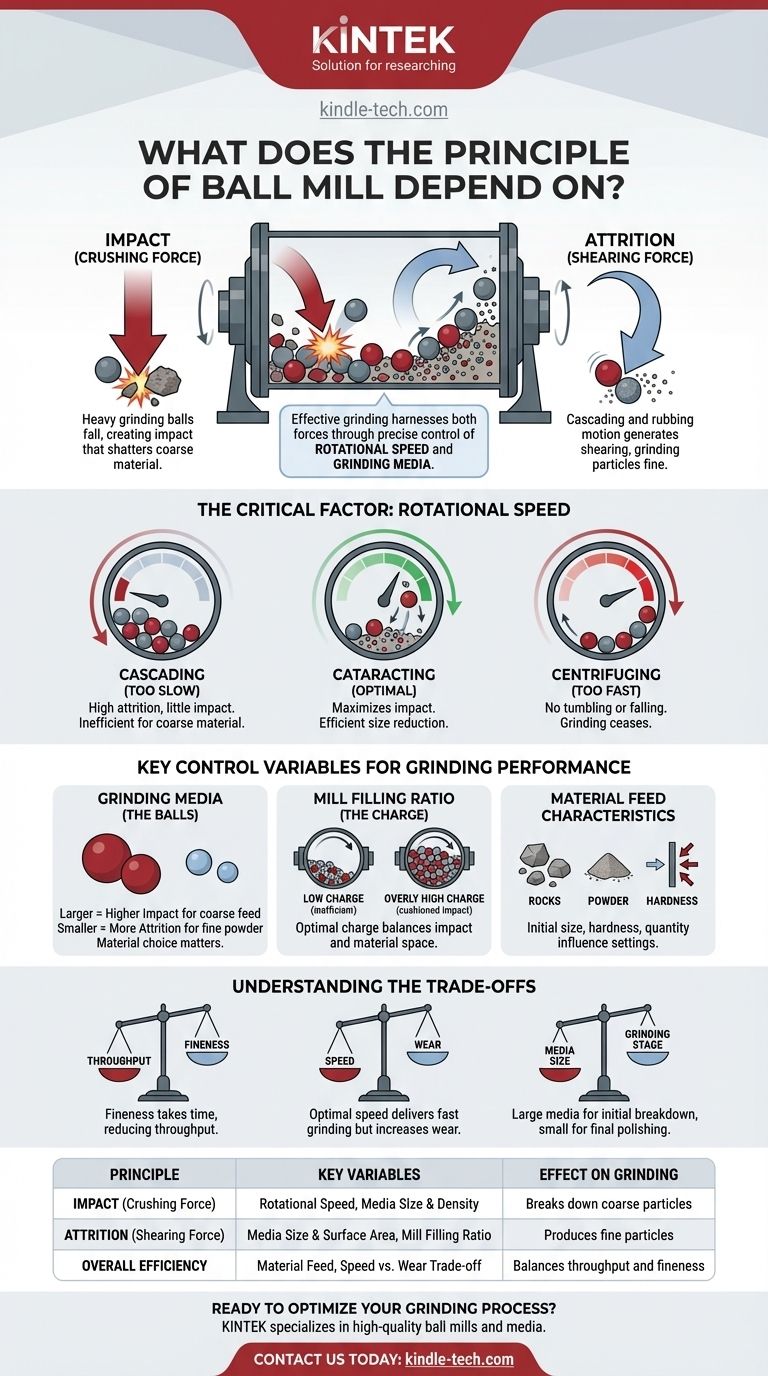

At its core, a ball mill operates on the twin principles of impact and attrition. The heavy grinding balls are lifted by the mill's rotation and then fall, creating a powerful impact force that shatters coarse material. Simultaneously, the cascading and rubbing motion of the balls against each other and the material generates attrition, a shearing force that grinds particles down to a fine consistency.

A ball mill is more than a simple container of tumbling balls. Its effectiveness depends on the precise control of rotational speed and grinding media to harness the forces of impact and attrition, turning a brute-force concept into a tunable process.

The Two Core Forces: Impact and Attrition

Understanding how to balance these two fundamental forces is the key to controlling the outcome of any grinding operation. They are distinct but work in concert.

Understanding Impact

Impact is the primary crushing force. As the mill's cylindrical shell rotates, it lifts the grinding media (the balls) and the material.

At the correct speed, gravity overcomes the centrifugal force, causing the balls to drop from near the top of the shell. This fall delivers a high-energy blow to the material below, effectively breaking down larger, coarse particles.

Understanding Attrition

Attrition is the grinding or shearing force. It occurs as the balls tumble over one another, rubbing against the material particles trapped between them.

This action is less dramatic than impact but is essential for reducing particles to a fine powder. Smaller balls, which have more surface area for a given weight, are particularly effective at generating attrition.

The Critical Factor: Rotational Speed

The speed of the mill's rotation is the single most important variable. It directly dictates whether impact or attrition dominates and determines the overall efficiency of the process.

Cascading (Too Slow)

At low speeds, the balls simply tumble or cascade down the face of the other media. This generates high levels of attrition but very little impact force. This is inefficient for breaking down hard, coarse materials.

Cataracting (The Optimal Speed)

This is the desired state for most applications. The speed is high enough to carry the balls to the top of the mill, where they detach and fall freely onto the material. This "cataracting" motion maximizes the force of impact, leading to efficient size reduction.

Centrifuging (Too Fast)

If the mill rotates too quickly, centrifugal force will pin the grinding media and the material to the inner wall of the shell. With no tumbling or falling, neither impact nor attrition can occur, and grinding ceases completely.

Key Control Variables for Grinding Performance

Beyond speed, several other factors must be managed to fine-tune the grinding process for a specific material and desired outcome.

Grinding Media (The Balls)

The characteristics of the balls are critical. Larger, heavier balls generate higher impact forces, ideal for breaking down large feed. Smaller balls create more surface contact and are better for producing very fine final products through attrition. The material of the balls—such as steel, ceramic, or rubber—is chosen based on the application's contamination and wear requirements.

Mill Filling Ratio (The "Charge")

This refers to the percentage of the mill's volume that is filled with grinding media. A low charge can lead to inefficient grinding and excessive liner wear. An overly high charge can cushion the balls' impact and limit the space available for the material to be ground effectively.

Material Feed Characteristics

The initial size, hardness, and quantity of the material being fed into the mill directly influence the other settings. Harder materials may require denser media and more impact force, while softer materials grind more quickly.

Understanding the Trade-offs

Optimizing a ball mill is a process of balancing competing factors. There is no single "perfect" setting, only the best setting for a specific goal.

Throughput vs. Fineness

Achieving an extremely fine particle size requires significant time and energy, which reduces the overall throughput (tons per hour) of the machine. A coarser product can be produced much more quickly.

Speed vs. Wear

Operating near the optimal cataracting speed delivers the fastest grinding but also causes the most significant wear on the mill's internal liner and the grinding media itself. This increases operational costs and downtime for maintenance.

Media Size vs. Grinding Stage

Large media is excellent for the initial breakdown of coarse feed but is inefficient at producing fine particles. Conversely, small media is excellent for final-stage polishing but cannot effectively break large chunks. This is why multi-stage grinding is sometimes necessary.

Making the Right Choice for Your Goal

Your operational settings should be a direct reflection of your primary objective.

- If your primary focus is rapid breakdown of coarse material: Prioritize impact force by using larger, denser grinding media and operating near the optimal cataracting speed.

- If your primary focus is producing very fine particles: Prioritize attrition by using a charge of smaller grinding media, which increases surface area and rubbing action.

- If your primary focus is maximizing operational efficiency: Carefully tune the rotational speed and media charge to achieve the target particle size in the shortest time without causing excessive, costly wear.

Mastering a ball mill is about moving beyond its simple principles to skillfully manipulate its operational variables.

Summary Table:

| Principle | Key Variables | Effect on Grinding |

|---|---|---|

| Impact (Crushing Force) | Rotational Speed, Media Size & Density | Breaks down coarse particles |

| Attrition (Shearing Force) | Media Size & Surface Area, Mill Filling Ratio | Produces fine particles |

| Overall Efficiency | Material Feed, Speed vs. Wear Trade-off | Balances throughput and fineness |

Ready to optimize your grinding process? The right lab equipment is crucial for achieving precise particle size and efficient operation. KINTEK specializes in high-quality ball mills and grinding media tailored to your laboratory's specific needs.

Contact us today to discuss how our solutions can enhance your research and development!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- Why is a planetary ball mill with zirconia grinding balls used for cellulose pretreatment? Unlock Catalytic Hydrolysis

- What is the function of high-energy ball mills during the physical activation of biochar? Enhance Cement Performance

- What role does a centrifugal ball mill play in the activation of magnesium-based alloy waste for hydrogen production?

- What technical challenge does the use of a planetary ball mill with alumina balls address? Solve MgAl2O4 Agglomeration

- What role does a high-energy planetary ball mill play in the synthesis of CoCrFeNi(W1-xMox)? Enhance Mechanical Alloying

- What role does a high-energy ball mill play in the synthesis of Li3PS4 and Na3PS4? Master Mechanochemical Synthesis

- What are the benefits of using a high-energy ball mill for NaSICON solid electrolytes? Optimize Your Material Synthesis