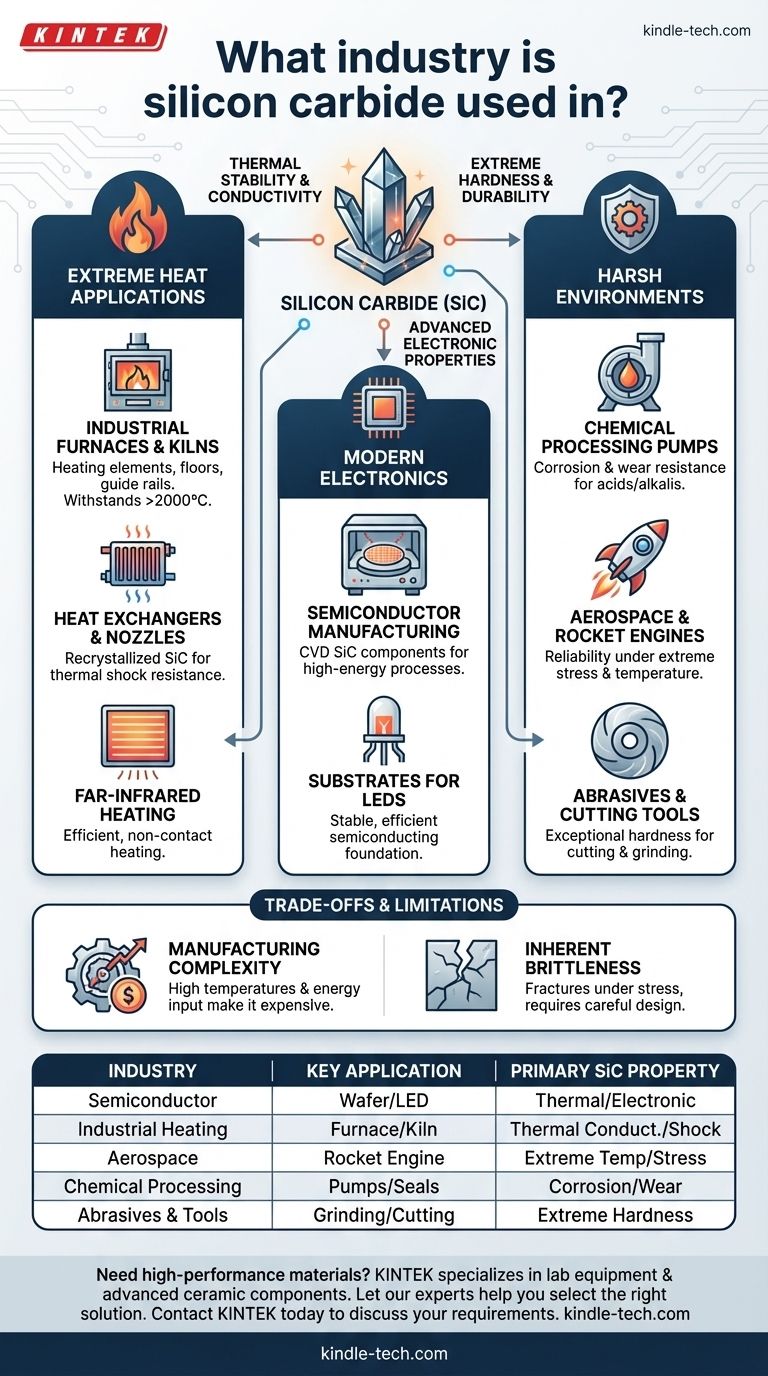

Silicon carbide is a high-performance ceramic used across a diverse range of critical industries, including semiconductor manufacturing, industrial heating, chemical processing, and aerospace. Its value stems from a unique combination of extreme hardness, high-temperature stability, and advanced electronic properties.

The widespread adoption of silicon carbide is driven by its ability to perform in environments where conventional materials fail. Its core value lies in a rare combination of extreme hardness, exceptional thermal stability and conductivity, and crucial electronic properties, making it an essential material for high-performance applications.

Why SiC Excels in Extreme Heat

The most common applications for silicon carbide leverage its incredible ability to withstand and conduct heat. It maintains its structural integrity at temperatures exceeding 2000°C, a point where most metals would have melted.

Industrial Furnaces and Kilns

Silicon carbide is a foundational material in high-temperature furnace construction. Its high refractoriness and thermal conductivity make it ideal for components like heating elements, furnace floors, and guide rails that must endure constant thermal cycling.

Heat Exchangers and Nozzles

Recrystallized silicon carbide, known for its purity and resistance to thermal shock, is frequently used for heat exchangers and combustion nozzles. These components can handle rapid temperature changes without cracking or failing.

Far-Infrared Heating

Due to its high blackness (a measure of its ability to emit thermal radiation), silicon carbide is also used to create far-infrared heating plates. This property allows for efficient, non-contact heating in various industrial processes.

The Foundation of Modern Electronics

Beyond its thermal and mechanical strength, silicon carbide possesses unique semiconducting properties that are enabling the next generation of electronics.

Semiconductor Manufacturing

Inside the chambers used to manufacture silicon wafers, components made of CVD silicon carbide are essential. They can withstand the high-energy plasmas and extreme temperatures required for processes like rapid thermal processing (RTP) and oxide etching.

Substrates for LEDs

Silicon carbide serves as an excellent semiconducting substrate for manufacturing high-intensity light-emitting diodes (LEDs). Its structure provides a stable and efficient foundation for building these electronic devices.

Unmatched Durability in Harsh Environments

Silicon carbide’s hardness and chemical inertness make it the material of choice for applications that demand extreme resistance to wear, corrosion, and abrasion.

Chemical Processing Pumps

In the chemical industry, magnetic and canned pumps often rely on silicon carbide components. These pumps handle highly corrosive acids, alkalis, and salts, and SiC provides the wear and corrosion resistance needed for 5-8 years of maintenance-free operation.

Aerospace and Rocket Engines

The ability to withstand extreme temperatures and erosive forces makes silicon carbide a valuable material for parts in rocket engines and other aerospace applications where reliability under stress is non-negotiable.

Abrasives and Cutting Tools

Historically, one of silicon carbide’s first major uses was in abrasives. Its exceptional hardness, second only to diamond, makes it perfect for sandpapers, grinding wheels, and durable cutting tools.

Understanding the Trade-offs

While its properties are exceptional, silicon carbide is not a universal solution. Understanding its limitations is key to using it effectively.

Manufacturing Complexity

Producing high-purity silicon carbide powder requires extremely high temperatures (often above 2000°C) and significant energy input. This complexity makes it more expensive than common metals or ceramics.

Inherent Brittleness

Like most advanced ceramics, silicon carbide is very hard but also brittle. It does not bend or deform under stress like a metal; instead, it fractures. This requires careful consideration during the design of any component.

Making the Right Choice for Your Application

Selecting silicon carbide is a decision based on overcoming a specific engineering challenge that lesser materials cannot handle.

- If your primary focus is extreme temperature and thermal shock resistance: Silicon carbide is a leading choice for furnace components, kilns, and heat exchangers.

- If your primary focus is high-power, high-efficiency electronics: SiC's properties as a wide-bandgap semiconductor make it essential for next-generation power devices and LED substrates.

- If your primary focus is chemical and wear resistance: For pumps and components in corrosive environments, SiC offers unparalleled longevity and reliability.

Ultimately, silicon carbide's adoption across these industries demonstrates its role as a problem-solving material for the most demanding engineering challenges.

Summary Table:

| Industry | Key Application | Primary SiC Property Utilized |

|---|---|---|

| Semiconductor Manufacturing | Wafer processing components, LED substrates | High-temperature stability, semiconducting properties |

| Industrial Heating | Furnace elements, kiln furniture, heat exchangers | Exceptional thermal conductivity & shock resistance |

| Aerospace | Rocket engine components | Ability to withstand extreme temperatures and stress |

| Chemical Processing | Seals, bearings, and pump components for corrosive fluids | Superior corrosion and wear resistance |

| Abrasives & Cutting Tools | Grinding wheels, sandpaper, cutting tools | Extreme hardness (second only to diamond) |

Need high-performance materials for your demanding applications?

Silicon carbide is essential for overcoming extreme challenges in temperature, corrosion, and wear. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including advanced ceramic components, to meet the precise needs of laboratories and industrial R&D departments.

Let our experts help you select the right materials to enhance your process efficiency and reliability.

Contact KINTEL today to discuss your specific requirements and discover the right solution for your project.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Versatile PTFE Solutions for Semiconductor and Medical Wafer Processing

- High Purity Zinc Foil for Battery Lab Applications

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- What is the maximum temperature for ceramics? Find the Right Material for Your High-Temp Application

- What determines the strength of ceramics? The surprising role of microscopic flaws in brittle failure

- Is ceramic temperature sensitive? Master Thermal Shock for Peak Performance

- What is the sintering process of advanced ceramics? Transform Powder into High-Performance Components

- What is the most biocompatible material for implants? A Guide to Titanium, Ceramics, and Polymers

- Are there any disadvantages of ceramics? The Trade-Off Between Hardness and Brittleness

- What is the function of the sintering process in ceramic manufacturing? Achieve High Density and Structural Integrity

- How is alumina ceramic made? A Guide to Manufacturing Methods and Material Properties