At its core, a planetary ball mill is a high-energy grinding instrument designed to pulverize materials into extremely fine powders, often reaching sub-micron or even nanometer scales. It operates using grinding jars mounted on a rotating "sun" wheel, which simultaneously spin on their own axes in the opposite direction. This compound motion generates immense impact and frictional forces, enabling significantly faster and finer grinding than conventional ball mills.

The defining characteristic of a planetary mill is its dual-rotation system, which generates a powerful Coriolis effect. This effect creates exceptionally high-energy impacts and friction, enabling the rapid comminution (size reduction) of hard, brittle, and fibrous materials that are difficult to process with other methods.

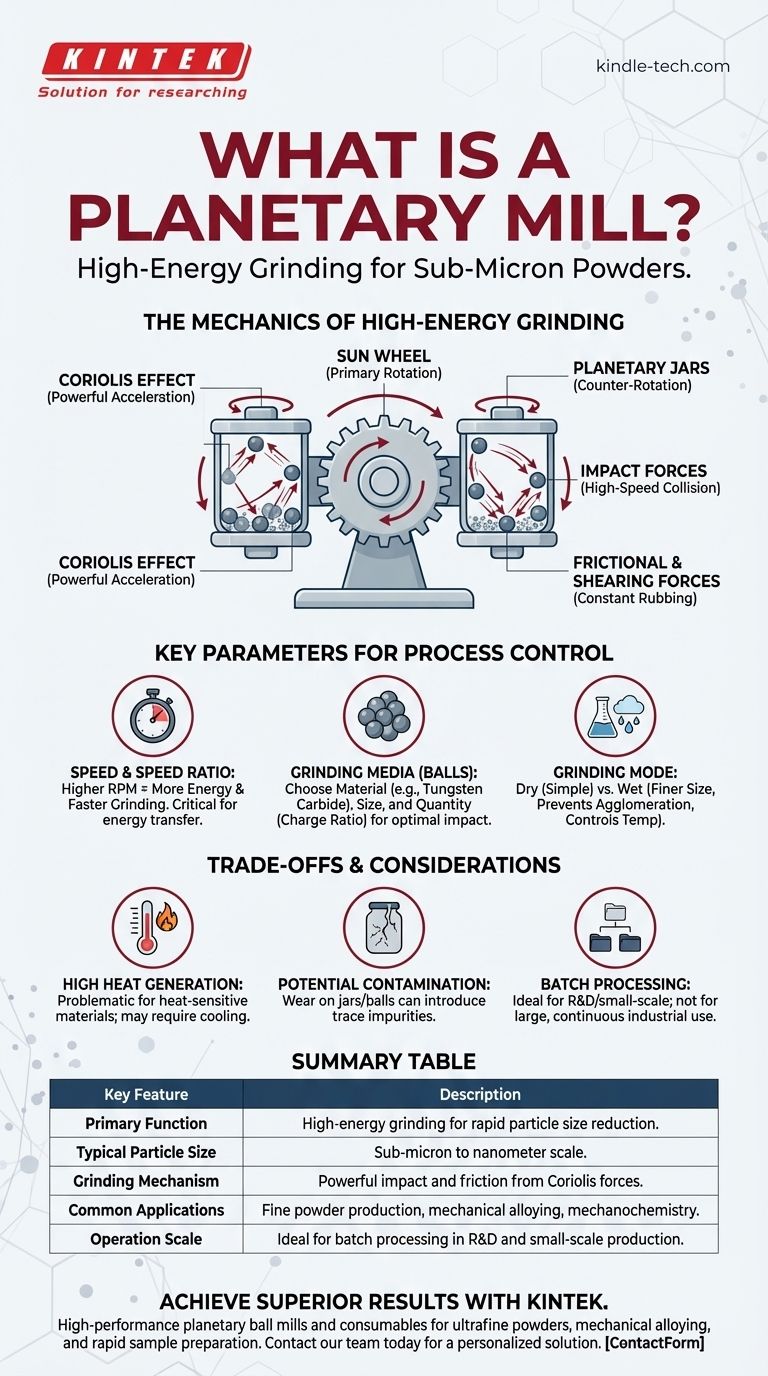

The Mechanics of High-Energy Grinding

A planetary mill's effectiveness comes from its unique and powerful motion. Understanding the forces it creates is key to understanding its purpose.

The Sun Wheel and Planetary Jars

The basic setup consists of a primary disc, known as the sun wheel, which rotates at a set speed. Mounted on this wheel are one or more grinding jars, the planets, which contain the material to be ground along with grinding media (typically balls).

As the sun wheel turns, the planetary jars are forced to rotate on their own axes in the opposite direction. This opposing motion is the foundation of the mill's power.

The Critical Role of Coriolis Forces

The superimposition of these two rotations creates a powerful acceleration on the grinding balls inside the jars, known as the Coriolis effect.

This force causes the grinding balls to detach from the inner wall of the jar. Instead of simply cascading down, they are flung at high speed across the jar's interior, creating powerful collisions.

Two Grinding Forces: Impact and Friction

This dynamic action results in two distinct grinding mechanisms working in tandem.

First, the high-speed flight of the balls leads to intense impact forces as they strike the material and the opposite jar wall. Second, the constant rubbing of balls against each other and the jar wall creates significant frictional and shearing forces. This combination is what makes the process so efficient.

Key Parameters for Process Control

Achieving the desired result with a planetary mill requires careful control over several key variables. The final particle size and processing time are not accidental; they are a direct result of these settings.

Speed and Speed Ratio

The rotational speed of the sun wheel is the primary determinant of the energy input. A higher speed results in more powerful impacts and faster grinding. The ratio between the sun wheel's speed and the planetary jars' speed is also critical for optimizing the energy transfer.

Grinding Media (Balls)

The choice of grinding balls is crucial. This includes their material (e.g., tungsten carbide for extreme hardness, zirconia for low contamination, stainless steel for general use), their size, and their quantity (the charge ratio). Larger, denser balls create higher impact energy.

Grinding Mode (Wet vs. Dry)

Grinding can be performed dry or wet (with a liquid medium). Dry grinding is simpler and often sufficient. Wet grinding can help achieve finer particle sizes, prevent particle agglomeration, and control the temperature inside the jar.

Understanding the Trade-offs and Limitations

While powerful, a planetary mill is not the right tool for every application. Its high-energy nature introduces specific considerations that must be managed.

High Energy Creates High Heat

The intense energy input inevitably generates significant heat within the grinding jar. This can be problematic for heat-sensitive materials and may require pauses in operation or external cooling systems to manage.

Potential for Sample Contamination

The powerful impacts can cause microscopic wear on the grinding jars and balls. This can introduce trace amounts of contamination into the sample. Choosing a jar and ball material that is harder than your sample and chemically inert is critical for high-purity applications.

Designed for Batch Processing

Planetary mills are fundamentally batch-based systems. They are ideal for research and development, quality control, or small-scale production but are not suitable for large-volume, continuous industrial processing.

Making the Right Choice for Your Goal

Selecting a planetary mill depends entirely on your material and desired outcome.

- If your primary focus is achieving the finest possible particle size: A planetary mill is an excellent choice, especially with wet grinding, to reach sub-micron or even nanometer-scale powders.

- If your primary focus is processing speed for lab-scale samples: The high-energy input makes it significantly faster than lower-energy mills for preparing small batches of material.

- If your primary focus is mechanical alloying or mechanochemistry: The intense impact forces are ideal for creating novel alloys or inducing chemical reactions directly in the solid state.

- If your primary focus is large-scale industrial production: You should investigate other milling technologies like tumbler, tower, or stirred mills designed for continuous, high-volume throughput.

Ultimately, understanding the unique forces at play within a planetary mill allows you to harness its power for precise and rapid materials processing.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Function | High-energy grinding for rapid particle size reduction. |

| Typical Particle Size | Sub-micron to nanometer scale. |

| Grinding Mechanism | Powerful impact and friction from Coriolis forces. |

| Common Applications | Fine powder production, mechanical alloying, mechanochemistry. |

| Operation Scale | Ideal for batch processing in R&D and small-scale production. |

Ready to achieve superior grinding results in your lab? KINTEK specializes in high-performance planetary ball mills and consumables, providing the precision and power you need for your most demanding materials. Whether your goal is ultrafine powders, mechanical alloying, or rapid sample preparation, our experts can help you select the perfect equipment. Contact our team today to discuss your application and get a personalized solution!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What function does a ball mill serve in LLZO synthesis? Maximize Your Solid-State Electrolyte Purity

- What size are planetary mill particles? Achieve Nanoscale Precision for Your Materials

- Through what mechanism does a mechanical ball mill function in top-down nanostructuring? Achieve Precision Nano-Sizing

- What is the function of a planetary ball mill in the initial synthesis of argyrodites? Unlock High-Energy Mixing

- Why are planetary ball mills used for intermetallic precursors? Achieve Precise Atomic-Level Mechanical Alloying

- What is the specific role of a planetary ball mill in the preparation of Ag-SnO2-Y2O3 composite powders?

- What is the primary function of a high-energy ball mill for LPSC? Optimize Sulfide Electrolyte Surface Modification

- What is the capacity of a ball mill? Optimize Your Grinding Throughput & Efficiency