At its core, a sieve shaker is a specialized laboratory instrument designed for particle size analysis. It automates the process of sifting granular or powdered material through a stack of test sieves, accurately separating the sample into different size fractions. This replaces inconsistent manual hand sieving with a repeatable, efficient, and precise mechanical method.

A sieve shaker's true purpose is to standardize and quantify the physical makeup of a material. By providing reliable data on particle size distribution, it transforms a basic sorting task into a critical quality control and research tool across numerous industries.

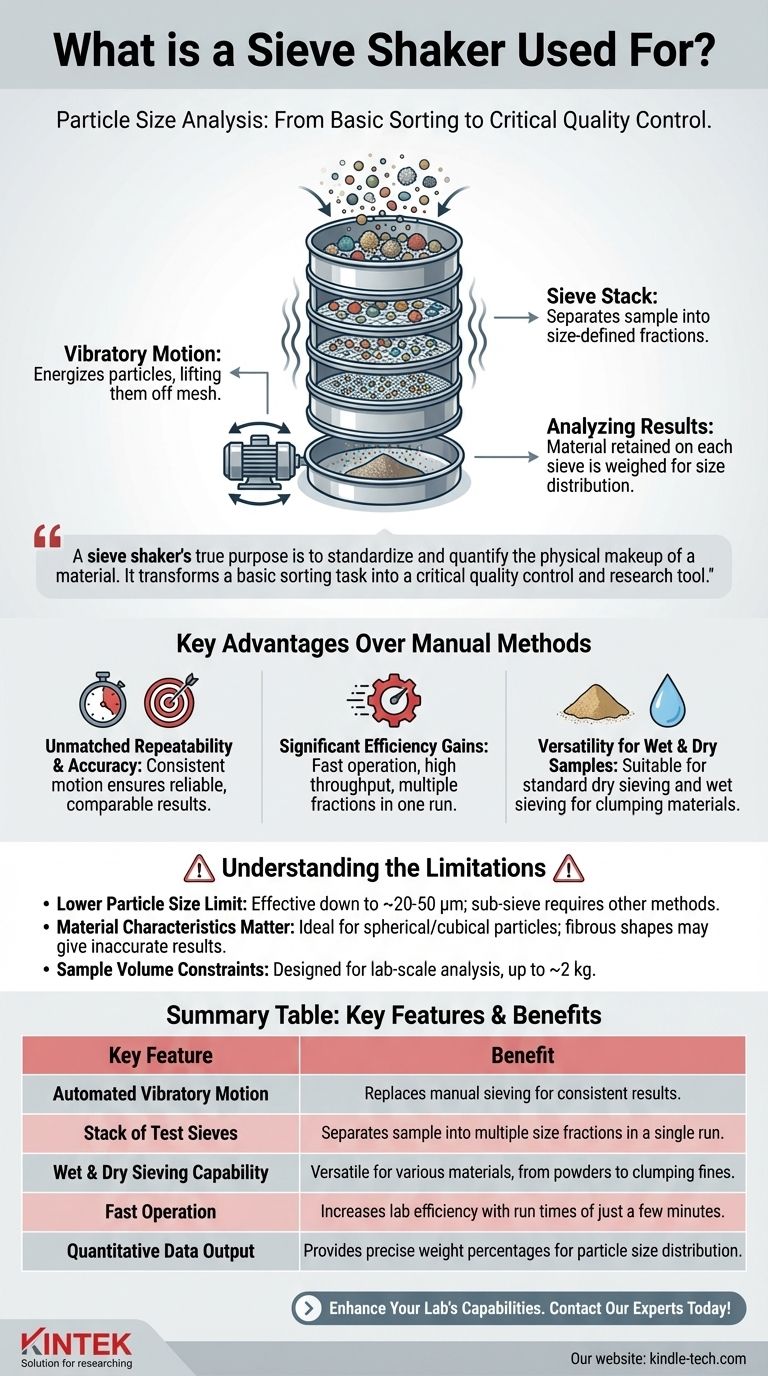

How a Sieve Shaker Achieves Precise Separation

A sieve shaker operates on a simple but highly controlled principle. It agitates a sample in a way that allows particles to be sorted by size, providing a clear picture of the material's composition.

The Principle of Vibratory Motion

The heart of the machine is a powerful motor that generates a consistent, often three-dimensional, shaking or throwing motion. This vibration energizes the particles, lifting them off the sieve mesh and giving each one an opportunity to pass through the openings if it is small enough.

The Role of the Sieve Stack

The shaker holds a vertical stack of interlocking test sieves. The sieve at the top has the largest mesh openings, and each subsequent sieve below it has progressively smaller openings. A solid collection pan sits at the very bottom.

As the shaker vibrates, particles travel down the stack until they reach a sieve with openings too small for them to pass through. This effectively segregates the initial sample into multiple size-defined fractions.

Analyzing the Results

After the shaking cycle is complete, the material retained on each sieve is weighed. This data is used to calculate the particle size distribution of the sample, often expressed as the weight percentage of material that falls within a specific size range.

Key Advantages Over Manual Methods

While manual sieving is possible, a mechanical shaker provides significant benefits that are essential for any professional setting.

Unmatched Repeatability and Accuracy

A sieve shaker eliminates the inconsistencies inherent in manual shaking. By using a controlled time and a uniform shaking motion, it ensures that results are highly repeatable and can be reliably compared between different samples, operators, or laboratories.

Significant Efficiency Gains

The process is remarkably fast, with typical run times lasting only a few minutes. This allows for a much higher throughput of samples compared to tedious and labor-intensive manual methods. Furthermore, it can separate a sample into two to seven distinct size segments in a single run.

Versatility for Wet and Dry Samples

Most sieve shakers are suitable for dry sieving, the standard method for powders and granules. Many can also be adapted for wet sieving, which is necessary for materials that tend to clump together or are extremely fine. In this process, a liquid (usually water) helps disperse the particles and wash them through the sieve openings.

Understanding the Trade-offs and Limitations

While highly effective, a sieve shaker is not the universal solution for all particle analysis. Understanding its limitations is key to using it correctly.

The Lower Particle Size Limit

Standard sieve shakers are most effective for particles down to approximately 20 to 50 micrometers (µm). Below this range, forces like static electricity and cohesion can cause fine particles to agglomerate, preventing them from passing through the mesh. For sub-sieve analysis, other methods like laser diffraction or sedimentation are required.

Material Characteristics Matter

The effectiveness of sieving depends heavily on particle shape. The process is ideal for roughly spherical or cubical particles. Long, flat, or fibrous materials may not orient correctly to pass through the sieve openings, potentially leading to inaccurate results.

Sample Volume Constraints

Sieve shakers are designed for laboratory-scale analysis, not bulk industrial processing. They typically handle sample sizes up to about 2 kg, which is sufficient for quality control or research purposes but not for separating large production volumes.

Making the Right Choice for Your Goal

A sieve shaker provides the quantitative data needed to control and understand particulate materials. Its application depends on your specific objective.

- If your primary focus is quality control: A sieve shaker provides the documented, repeatable evidence needed to ensure raw materials and final products meet precise size specifications.

- If your primary focus is research and development: This tool is essential for characterizing new materials and understanding how particle size distribution impacts properties like flowability, dissolution rate, or reactivity.

- If your primary focus is process optimization: It helps you diagnose issues by analyzing material from different stages of production, replacing slow or inconsistent manual spot-checks.

By providing reliable and accurate particle size data, a sieve shaker empowers you to make informed decisions about your material's quality, behavior, and performance.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Automated Vibratory Motion | Replaces manual sieving for consistent, repeatable results. |

| Stack of Test Sieves | Separates a sample into multiple size fractions in a single run. |

| Wet & Dry Sieving Capability | Versatile for various materials, from powders to clumping fines. |

| Fast Operation | Increases lab efficiency with run times of just a few minutes. |

| Quantitative Data Output | Provides precise weight percentages for particle size distribution. |

Ready to enhance your lab's particle analysis capabilities?

KINTEK specializes in high-quality lab equipment, including reliable sieve shakers designed to meet the rigorous demands of your quality control and research. Our instruments deliver the accuracy and repeatability you need to ensure product quality and optimize your processes.

Contact our experts today to find the perfect sieve shaker for your specific materials and application!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Oscillating Orbital Shaker

People Also Ask

- What is the primary function of standard sieving systems? Master Matrix Uniformity for Advanced Composites

- How do you maintain a sieve shaker? Ensure Accurate Particle Size Analysis Every Time

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy

- What role does a laboratory orbital shaker play in AHP pretreatment? Achieve Uniform Delignification for Cassava Stems

- How does a standard sieving system contribute to the quality control of recycled concrete aggregates?

- What are the primary functions of high-precision impact vibratory sieving machines in titanium alloy classification?

- How do static culture and shaking culture affect the morphology of BC? Optimize Lab Shaker Results

- How do laboratory shakers ensure accuracy in adsorption studies? Optimize Your Kinetics and Isotherm Data Today