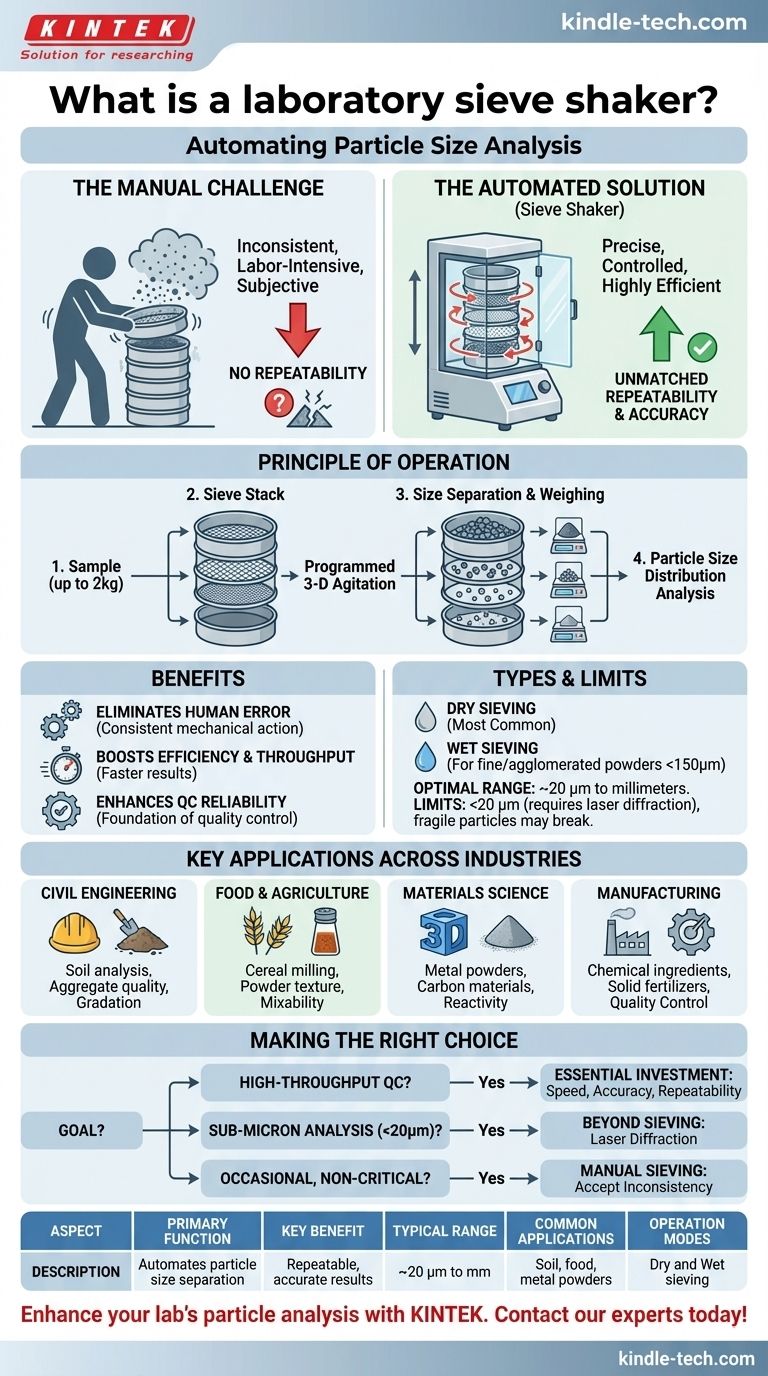

In short, a laboratory sieve shaker is a machine that automates the process of particle size analysis. It vigorously and consistently agitates a stack of test sieves to separate granular materials based on their size. This provides a quantitative understanding of the particle size distribution within a sample, a critical parameter in countless industrial and research applications.

A sieve shaker's fundamental purpose is to replace inconsistent, labor-intensive manual sieving with an objective, repeatable, and highly efficient method. It transforms a basic separation task into a reliable scientific measurement for quality control and material characterization.

The Core Problem: The Need for Consistent Particle Sizing

Before understanding the tool, we must understand the problem it solves. The size and distribution of particles in a material can dramatically affect its physical properties, chemical reactivity, and overall quality.

Why Particle Size Matters

In fields from civil engineering to pharmaceuticals, knowing the particle size distribution is not optional. It determines the strength of concrete, the dissolution rate of a drug, the texture of a food product, and the safety of fine powders. Inconsistent particle sizing leads to inconsistent product quality.

The Limits of Manual Sieving

Historically, this analysis was done by hand. An operator would manually shake a stack of sieves, a process that is slow, physically demanding, and highly subjective. The results depend entirely on the operator's technique, duration, and effort, making it nearly impossible to achieve repeatable results between different people or even different tests by the same person.

How a Sieve Shaker Solves the Problem

A sieve shaker introduces mechanical precision and control to the process, eliminating the variables of manual work.

The Principle of Operation

A sample of up to 2 kg is placed on the top sieve in a stack. This stack consists of multiple sieves with progressively smaller mesh openings toward the bottom, ending with a solid collection pan.

The shaker then agitates the entire stack with a consistent, programmed motion. This is often a 3-D throwing motion, combining vertical tapping with horizontal rotation to ensure particles are challenged against the mesh from all angles.

Smaller particles pass through the mesh openings until they reach a sieve they are too large to clear, effectively sorting the sample by size fractions. After the cycle, the material retained on each sieve is weighed to calculate the particle distribution.

The Key Benefit: Repeatability and Accuracy

The primary advantage of a sieve shaker is its repeatability. By using a controlled and identical mechanical action for every test, it eliminates human error and ensures that any two identical samples will produce the same result. This is the foundation of reliable quality control.

Wet vs. Dry Sieving

Most materials are analyzed using dry sieving. However, for very fine powders (typically below 150 µm) that tend to agglomerate or stick together due to static electricity, wet sieving is used. A liquid (usually water) is introduced to help disperse the particles and wash them through the sieve meshes.

Key Applications Across Industries

The use of sieve shakers is widespread, touching nearly every industry that handles granular materials.

Civil Engineering and Geotechnical

Sieve shakers are fundamental for soil analysis and the quality assessment of aggregates used in concrete and asphalt. The particle distribution, or "gradation," is a primary factor in determining the stability and strength of these construction materials.

Food and Agriculture

In this sector, shakers ensure the consistent milling of cereals, grains, and spices. They verify that powders meet specifications for texture and mixability, impacting everything from the feel of a sauce to the baking properties of flour.

Manufacturing and Materials Science

Sieve shakers are used for quality control of metal powders for 3D printing, raw carbon materials, solid fertilizers, and chemical ingredients. Accurate sizing ensures proper reactivity, flowability, and final product performance.

Understanding the Trade-offs and Limitations

While highly effective, a sieve shaker is not the universal solution for all particle analysis. Understanding its limitations is key to using it correctly.

Cost vs. Throughput

The initial investment in a sieve shaker is higher than relying on manual methods. However, this cost is quickly justified by the dramatic increase in efficiency, accuracy, and sample throughput, especially in a quality control environment.

Particle Size Range

Sieve analysis is most effective for particles ranging from several millimeters down to about 20 micrometers (µm). Below this size, physical sieving becomes impractical. For analyzing sub-micron or nano-particles, other technologies like laser diffraction or dynamic light scattering are required.

Sample Integrity

The vigorous mechanical action of a shaker can break down very fragile or friable particles. This can skew the results by creating more fine particles than were originally in the sample. In such cases, a gentler method may be needed.

Making the Right Choice for Your Lab

Selecting the right method depends entirely on your specific analytical goals.

- If your primary focus is high-throughput quality control: A sieve shaker is an essential investment for its speed, accuracy, and unmatched repeatability.

- If your primary focus is analyzing particles smaller than 20 µm: You must look beyond sieving to technologies like laser diffraction designed for the sub-micron range.

- If your primary focus is occasional, non-critical analysis of coarse materials: Manual sieving may suffice, but you must accept the inherent inconsistencies in your results.

By automating the fundamental process of sieving, a shaker transforms particle analysis from a subjective chore into a reliable and efficient scientific measurement.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Automates particle size separation and analysis. |

| Key Benefit | Provides repeatable, accurate results, eliminating human error from manual sieving. |

| Typical Particle Range | ~20 µm to several millimeters. |

| Common Applications | Soil/aggregate testing, food & agriculture, pharmaceuticals, metal powders, chemicals. |

| Operation Modes | Dry sieving (most common) and wet sieving (for fine, agglomerated powders). |

Ready to enhance your lab's particle analysis with reliable, repeatable results?

KINTEK specializes in high-quality laboratory sieve shakers and consumables designed to meet the rigorous demands of quality control and research. Whether you're in civil engineering, pharmaceuticals, or food science, our equipment ensures the accuracy and efficiency your lab requires.

Contact our experts today to find the perfect sieving solution for your specific application and sample type!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What is the significance of a hand sieve shaker? Achieve Standardized Particle Size Analysis

- How do laboratory constant temperature shakers ensure material uniformity? Optimize Bimetallic Nanocatalyst Synthesis

- What are the different types of sieve shakers? Match the Shaker to Your Material for Accurate Particle Analysis

- What is a sieving shaker? Automate Your Particle Size Analysis for Accurate Results

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What are the applications of sieving machine? From Mining to Pharmaceuticals

- What role does a constant-temperature shaker play in batch adsorption experiments? Key Insights for Lab Efficiency

- What are the disadvantages of a sieve shaker? Key Limitations for Accurate Particle Sizing