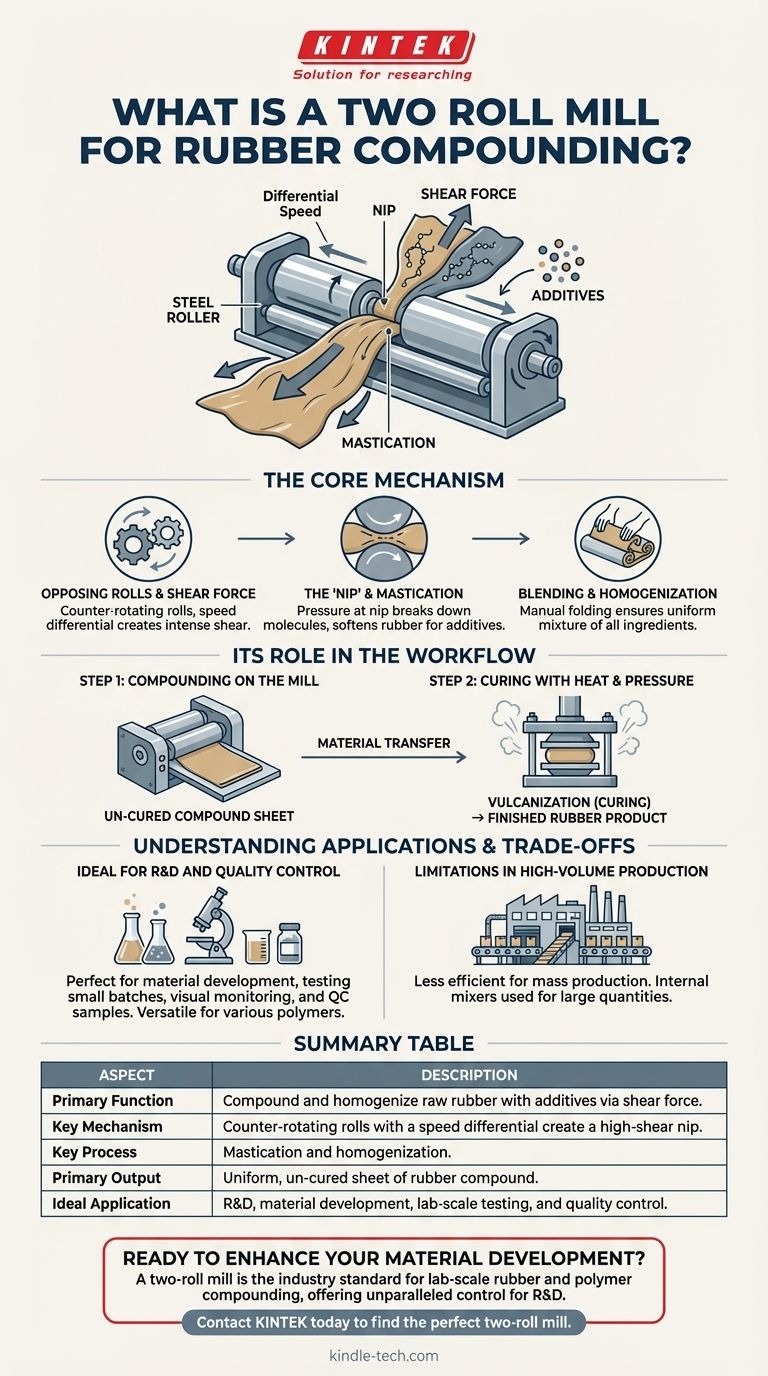

At its core, a two roll mill is a machine that transforms raw rubber and a collection of separate ingredients into a single, uniform compound. It uses two large, counter-rotating steel rollers to apply intense pressure and shear force, effectively kneading and blending the materials together into a workable sheet.

The two roll mill's primary function is not just mixing; it is to fundamentally change the material's properties through mechanical work, making the raw polymer receptive to additives and creating a completely homogenous, un-cured rubber compound ready for the next stage of manufacturing.

The Core Mechanism: How It Creates a Compound

A two roll mill may appear simple, but its effectiveness lies in the precise application of mechanical forces. The process relies on a few key principles.

Opposing Rolls and Shear Force

The machine consists of two horizontal steel rolls positioned closely together. These rolls rotate towards each other but at slightly different speeds.

This speed differential is critical. It creates an intense shear force that pulls and stretches the material as it passes between the rolls, ensuring ingredients are smeared and dispersed rather than just stirred.

The 'Nip' and Material Mastication

The narrow gap between the two rolls is known as the nip. As rubber is fed into the nip, it is subjected to immense pressure.

This pressure and shearing action breaks down the long molecular chains of the raw rubber, a process called mastication. This softens the rubber, reduces its elasticity, and makes it "stickier," allowing powdered ingredients like carbon black, sulfur, and other curatives to be blended in effectively.

Blending and Homogenization

An operator continuously works the material on the mill. The rubber forms a sheet around one of the rolls, and the operator uses a knife to cut and fold this sheet back into the nip.

This manual folding process is essential for achieving a homogenous mixture. It ensures that all parts of the batch are repeatedly passed through the high-shear nip area, distributing every additive evenly throughout the rubber.

Its Role in the Manufacturing Workflow

The two roll mill is a critical piece of equipment, but it is just one step in the larger process of creating a finished rubber product. Understanding its position in the workflow is key.

Step 1: Compounding on the Mill

This is the primary function we've discussed. The mill takes raw polymer and additives and creates a specific rubber recipe or formula. The output is a soft, pliable, un-cured sheet of compounded rubber.

Step 2: Curing with Heat and Pressure

The compounded rubber sheet is not yet a finished product. It lacks the stable, durable properties we associate with rubber.

The material must then be transferred to a machine like a hydraulic hot press. This machine applies controlled heat and pressure over time, initiating a chemical reaction called vulcanization (or curing). This process cross-links the polymer chains, transforming the soft compound into a strong, elastic, and finished rubber part.

Understanding the Applications and Trade-offs

While powerful, the two roll mill is not the only solution for rubber mixing. Its value lies in its specific strengths and applications.

Ideal for R&D and Quality Control

The open, manual nature of a two roll mill makes it perfect for material development and testing. Engineers can create small, precise batches of new formulas, visually monitor the mixing process, and easily take samples for quality control checks.

Its versatility also extends to mixing other polymers, such as for PVC color sampling and plastics formulation tests, making it an indispensable tool in a laboratory setting.

Limitations in High-Volume Production

The hands-on operation and batch-style nature of a two roll mill make it less efficient for mass production.

For high-volume manufacturing, large-scale facilities typically use internal mixers (like a Banbury mixer). These are enclosed, automated systems that can process much larger quantities of rubber compound more quickly, though with less direct visual feedback.

Making the Right Choice for Your Goal

The decision to use a two roll mill depends entirely on your objective.

- If your primary focus is material development or lab-scale testing: The two roll mill is the industry standard, offering unparalleled control and feedback for creating precise formulations.

- If your primary focus is process education or quality assurance: Its visual and hands-on nature makes it an excellent tool for training operators and for verifying the properties of production batches.

- If your primary focus is large-scale, continuous manufacturing: The mill serves as a secondary machine for warming up pre-mixed compounds or for specialized runs, while a more automated internal mixer handles the primary compounding.

Ultimately, the two roll mill is the foundational machine for imparting the desired properties into a polymer, transforming raw ingredients into a purpose-built material.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | To compound and homogenize raw rubber with additives via intense shear force. |

| Key Mechanism | Counter-rotating rolls with a speed differential create a high-shear "nip." |

| Key Process | Mastication (softening rubber) and homogenization (blending ingredients). |

| Primary Output | A uniform, un-cured sheet of rubber compound ready for vulcanization. |

| Ideal Application | R&D, material development, lab-scale testing, and quality control. |

Ready to enhance your material development and quality control processes?

A two-roll mill is the industry standard for lab-scale rubber and polymer compounding, offering unparalleled control for R&D. KINTEK specializes in providing high-quality lab equipment, including two-roll mills, to meet the precise needs of laboratories and research facilities.

Contact KINTEK today to find the perfect two-roll mill for your application and discover how our expertise can support your innovation in polymer processing.

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- What is the twin screw extrusion process? A Guide to Advanced Mixing & Compounding

- What is an electric mixer called? Hand Mixer vs. Stand Mixer Explained

- What is the meaning of calendering? Achieve Superior Surface Finish and Material Uniformity

- How does a vulcanizing machine work? Mastering the Art of Rubber Transformation

- What is the most commonly used vulcanizing? Discover the Power of Sulfur Vulcanization

- What is the manufacturing process of rubber? From Raw Material to Durable End Product

- How profitable is injection molding? Unlock High-Volume Manufacturing Profitability

- Is co-extrusion the same as dual extrusion? Unlock the Power of Multi-Material Plastic Profiles