In the world of casting, an insert is a pre-formed object placed into the mold cavity before the molten material is introduced. When the material solidifies, it forms around or bonds to the insert, making it an integral part of the final piece. This allows for the creation of features or the integration of different materials that would be difficult or impossible with a simple mold alone.

An insert is not just a part of the mold; it is a strategic tool used to overcome the inherent limitations of casting. It enables the creation of complex internal geometries, multi-material components, and more serviceable, cost-effective tooling.

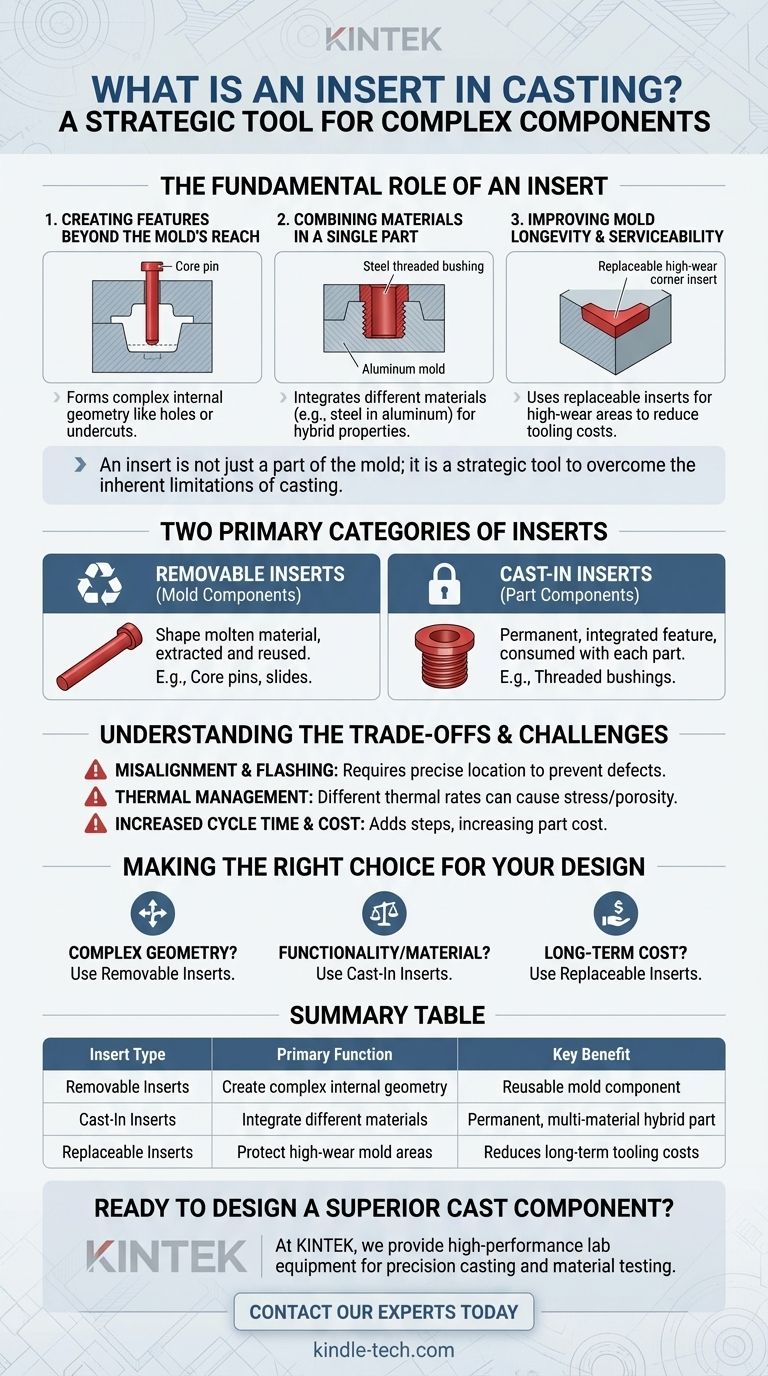

The Fundamental Role of an Insert

Understanding inserts is about seeing the mold as more than just a void to be filled. It becomes a jig for assembling a more complex product in a single, high-speed step.

Creating Features Beyond the Mold's Reach

Many cast parts require internal features like holes, threads, or passages. While some simple holes can be created by the two halves of the mold coming together, complex internal geometry requires an insert.

A common example is a core pin. This is a simple steel rod (an insert) placed in the mold. Molten metal flows around it, and after the part cools, the pin is removed, leaving a perfectly formed, smooth hole.

Combining Materials in a Single Part

This is where inserts provide immense value. An insert made of a different material can be placed in the mold to become a permanent part of the final component.

This creates a hybrid part with properties unattainable with a single material. For example, a strong, wear-resistant steel threaded bushing can be cast into a lighter aluminum housing, providing durable threads without making the entire part out of heavy, expensive steel.

Improving Mold Longevity and Serviceability

Some features on a cast part, like sharp corners or thin posts, cause rapid wear on the mold itself. Machining these features directly into a large, expensive mold block is a liability.

Instead, these high-wear features can be designed as small, replaceable inserts made of hardened tool steel. When the feature wears out, you don't replace the entire mold—you simply swap out the small, inexpensive insert, dramatically reducing long-term tooling costs.

Two Primary Categories of Inserts

While their function varies, inserts fall into two main classes based on whether they stay with the part or with the mold.

Removable Inserts (Mold Components)

These are functional parts of the tooling, made from durable materials like tool steel. Their job is to shape the molten material, but they are not part of the final product.

After the part solidifies, these inserts are extracted from the part and reused for the next cycle. Core pins, slides for creating undercuts, and logos are all examples of removable inserts.

"Cast-In" Inserts (Part Components)

These inserts are placed into the mold with the intention of them becoming a permanent, integrated feature of the final product. They are consumed in the process and a new one is required for each part.

Common examples include electrical contacts, bearing surfaces, reinforcing structural elements, and the aforementioned threaded bushings. This process is often called insert molding.

Understanding the Trade-offs and Challenges

While powerful, using inserts requires careful engineering and introduces complexities that must be managed.

The Risk of Misalignment and Flashing

The insert must be held securely in the correct position within the mold as high-pressure molten metal is injected.

Any slight movement or gap can cause the metal to "flash," or seep into unintended areas, creating defects and potentially damaging the mold. Precise locational features are critical for both the insert and the mold.

Thermal Management Complexity

An insert, especially one made of a different material, will heat up and cool down at a different rate than the surrounding mold and molten alloy.

This thermal differential can introduce internal stress in the final part or cause localized porosity. The design of the mold's cooling channels must account for the thermal mass of the insert to ensure uniform solidification.

Increased Cycle Time and Cost

The process of placing an insert into the mold adds a step to the manufacturing cycle. Whether done manually by an operator or with automation, it takes time.

This can increase the cycle time and the cost per part compared to a simpler casting process without inserts. The value added by the insert must justify this additional operational cost.

Making the Right Choice for Your Design

Using inserts is a design decision that should be made based on clear product requirements.

- If your primary focus is creating complex internal geometry: Use removable inserts like core pins and slides to form holes, passages, or undercuts efficiently.

- If your primary focus is adding functionality or a different material: Use cast-in inserts like threaded studs or hardened wear surfaces to create a robust, multi-material component in a single step.

- If your primary focus is long-term manufacturing cost: Design high-wear features of your mold as replaceable inserts to avoid costly tool replacement and minimize downtime.

Ultimately, viewing inserts as a strategic design element empowers you to create more sophisticated, functional, and cost-effective cast components.

Summary Table:

| Insert Type | Primary Function | Key Benefit |

|---|---|---|

| Removable Inserts | Create complex internal geometry (holes, undercuts) | Reusable mold component; efficient for complex shapes |

| Cast-In Inserts | Integrate different materials (e.g., steel threads in aluminum) | Creates a permanent, multi-material hybrid part |

| Replaceable Inserts | Protect high-wear areas of the mold | Reduces long-term tooling costs and downtime |

Ready to design a superior cast component?

At KINTEK, we specialize in providing the high-performance lab equipment and consumables needed for precision casting and material testing. Whether you're prototyping with inserts or scaling up production, our solutions help you achieve precise thermal control and material analysis.

Let's optimize your casting process together. Contact our experts today to discuss your specific laboratory and production needs!

Visual Guide

Related Products

- Copper Foam

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Laboratory Hybrid Tissue Grinding Mill

- Infrared Heating Quantitative Flat Plate Press Mold

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- What are the proper storage conditions for nickel and copper foam? A Guide to Preserving Performance

- What role does convection play in heat transfer? Understanding Heat Movement in Fluids

- What are the factors that affect heat transfer? Master the Key Variables for Optimal Thermal Performance

- How can different materials have different heat capacity? Unlocking the Microscopic Secrets of Energy Storage

- What are the common applications of copper foam? A Guide to Its High-Performance Uses