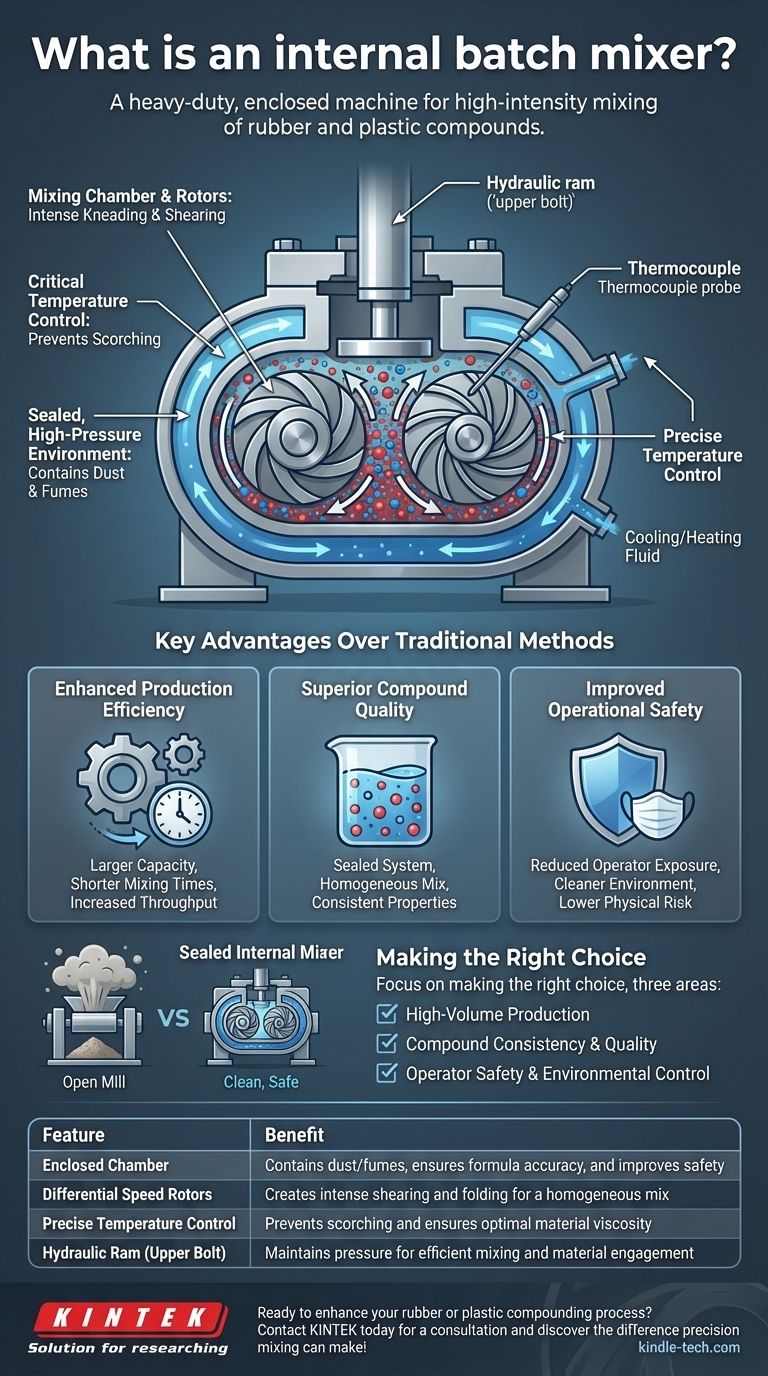

At its core, an internal batch mixer is a heavy-duty, enclosed machine designed for the high-intensity mixing of materials, primarily rubber and plastic compounds. It operates by using two specially designed rotors that rotate in opposite directions and at different speeds within a sealed chamber. This action kneads, shears, and disperses the raw materials into a completely uniform, or homogeneous, final compound.

The true value of an internal batch mixer is not just its ability to mix materials; it is the high degree of control, efficiency, and safety it provides. By enclosing the process, it revolutionizes production quality and workplace conditions compared to traditional open-mill mixing.

How an Internal Mixer Achieves a Homogeneous Compound

To understand the mixer's effectiveness, you must look at how its core components work together as a system. The final quality of the compound is a direct result of this mechanical and thermal synergy.

The Mixing Chamber and Rotors

The heart of the machine is the mixing chamber. This is typically a robust, C-shaped steel casting designed to withstand immense pressure and high temperatures.

Inside this chamber are two powerful rotors. These are not simple paddles; they are engineered with complex geometries designed to continuously pull material into the high-shear zone between them.

The rotors turn at slightly different speeds. This differential is critical, as it creates a powerful shearing and wiping action that stretches, folds, and combines the ingredients on a microscopic level.

Critical Temperature Control

Precise temperature management is non-negotiable for quality mixing, especially with rubber. The mixing chamber is jacketed, allowing a cooling fluid (usually water) or heating medium to circulate around it.

This system, combined with thermocouples placed inside the chamber, provides real-time temperature data. Operators can maintain the optimal temperature to ensure the material has the right viscosity for mixing without "scorching" or curing prematurely.

The Sealed, High-Pressure Environment

Unlike an open mill, the entire process occurs within a sealed environment. A hydraulic ram, or "upper bolt," pushes down on the material, keeping it contained and ensuring it remains engaged with the rotors.

This enclosed design prevents dust and fumes from escaping, creating a cleaner and safer work environment. It also minimizes the loss of fine powders and chemical agents, which is critical for maintaining the exact formulation of the compound.

Key Advantages Over Traditional Methods

The shift from open mixers (like two-roll mills) to internal mixers was driven by clear, measurable benefits in production and quality.

Enhanced Production Efficiency

Internal mixers can handle a much larger capacity per batch than an open mill.

Combined with significantly shorter mixing times, this results in a dramatic increase in overall production throughput. A single internal mixer can often replace multiple open mills.

Superior Compound Quality

The enclosed system prevents the loss of compounding agents to the air, ensuring the final batch perfectly matches the intended formula.

The intense, controlled shearing action results in a more uniform dispersion of ingredients. This leads to a higher-quality final product with more consistent physical properties.

Improved Operational Safety

By containing dust and hazardous materials, internal mixers drastically reduce operator exposure to airborne particulates.

The automated and enclosed nature of the process also reduces the physical labor intensity and the risk of operators getting caught in moving machinery, a significant hazard with open mills.

Making the Right Choice for Your Goal

The decision to use an internal mixer is driven by specific manufacturing objectives related to scale, quality, and safety.

- If your primary focus is high-volume production: The internal mixer's large batch size and short cycle times deliver unmatched throughput for industrial-scale operations.

- If your primary focus is compound consistency and quality: The enclosed, highly controlled environment ensures minimal material loss and provides the repeatable batch-to-batch quality demanded by high-performance applications.

- If your primary focus is operator safety and environmental control: The internal mixer is the definitive choice for creating a modern, clean, and safe workplace by minimizing dust and reducing physical hazards.

Understanding these core principles allows you to see the internal mixer not just as a piece of equipment, but as a strategic asset for modern manufacturing.

Summary Table:

| Feature | Benefit |

|---|---|

| Enclosed Chamber | Contains dust/fumes, ensures formula accuracy, and improves safety. |

| Differential Speed Rotors | Creates intense shearing and folding for a homogeneous mix. |

| Precise Temperature Control | Prevents scorching and ensures optimal material viscosity. |

| Hydraulic Ram (Upper Bolt) | Maintains pressure for efficient mixing and material engagement. |

Ready to enhance your rubber or plastic compounding process?

An internal batch mixer from KINTEK can be the strategic asset your operation needs to boost production volume, guarantee batch-to-batch consistency, and create a safer workplace. Our experts are ready to help you select the perfect lab equipment for your specific mixing goals.

Contact KINTELK today for a consultation and discover the difference precision mixing can make!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?

- What are laboratory mixers used for? Achieve Perfect Sample Homogeneity and Reliable Results

- What is a laboratory mixer? A Guide to Achieving Perfect Sample Homogeneity