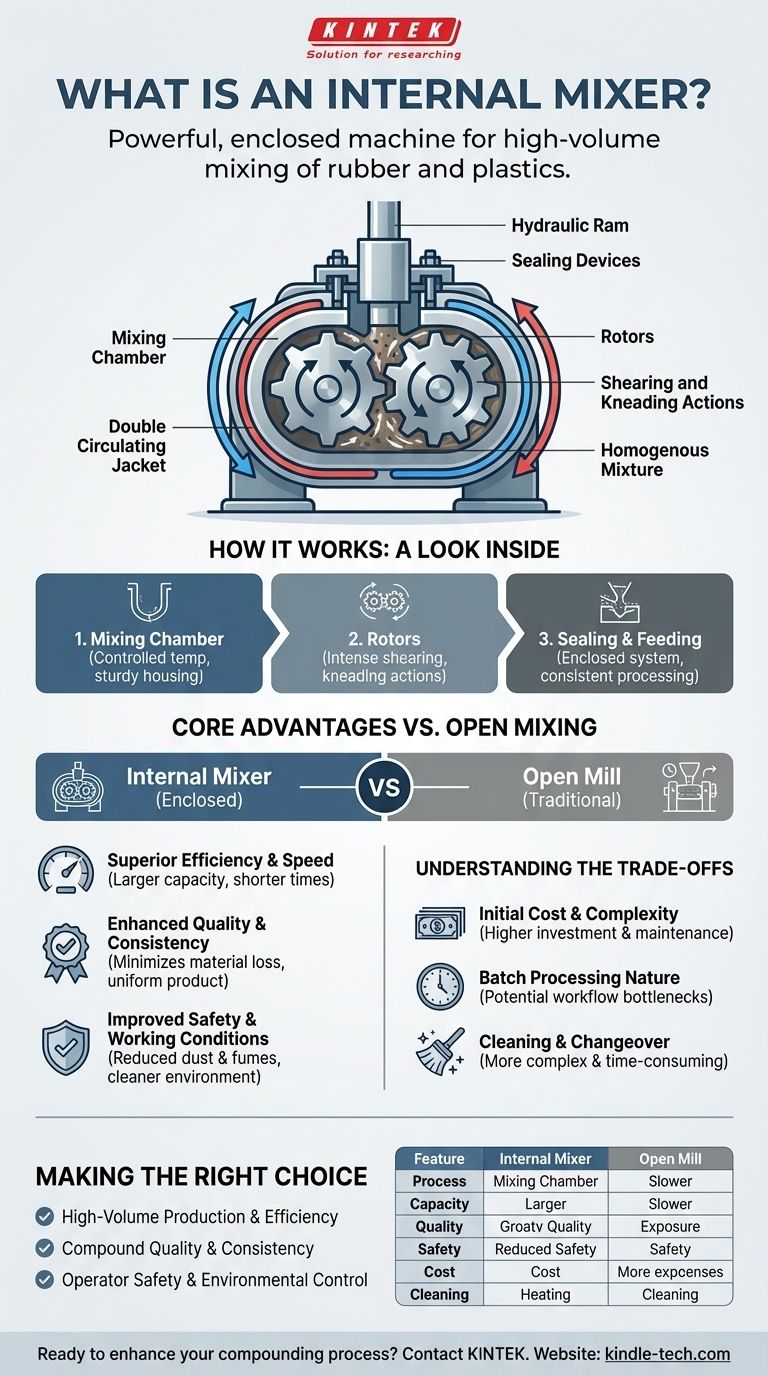

An internal mixer is a powerful, enclosed machine designed for the high-volume mixing and compounding of materials, primarily rubber and plastics. Unlike open mills, it contains the entire process within a closed chamber where two specialized rotors shear and blend the materials into a homogenous mixture.

The true value of an internal mixer lies in its ability to create a highly controlled environment. This enclosed design delivers superior efficiency, compound quality, and operator safety, making it the standard for modern, large-scale production.

How an Internal Mixer Works: A Look Inside

To understand its advantages, we must first examine its core components and their functions. The machine's design is centered on maximizing mixing force in a contained space.

The Mixing Chamber

The heart of the machine is the mixing chamber. This is a sturdy, C-shaped housing where the entire blending process takes place.

Crucially, the chamber is surrounded by a double circulating jacket. This allows for the precise application of heating or cooling fluids, giving operators tight control over the temperature of the mix.

The Rotors

Inside the chamber, two heavy-duty rotors do the actual work. They are designed to rotate toward each other, typically at slightly different speeds.

This differential speed creates intense shearing and kneading actions, which break down the raw materials and disperse additives evenly throughout the batch.

The Sealing and Feeding System

The entire system is enclosed. A hydraulic or pneumatic ram pushes down on the material from the top, ensuring it remains in contact with the rotors.

Specialized sealing devices prevent materials and fumes from escaping the chamber, which is critical for both safety and process consistency.

The Core Advantages Over Open Mixing

The design of an internal mixer offers clear and significant benefits compared to traditional open-mill mixers.

Superior Efficiency and Speed

An internal mixer has a much larger mixing capacity and operates with significantly shorter mixing times. This directly translates to higher production efficiency for any high-volume operation.

Enhanced Quality and Consistency

The enclosed chamber prevents the loss of compounding agents due to flying dust. This ensures the final batch accurately reflects the intended formula and improves overall product quality and consistency.

Improved Safety and Working Conditions

Containing the process dramatically reduces dust and fumes in the workplace. This creates a cleaner, safer environment for operators and simplifies environmental compliance. The potential for automation also reduces manual labor intensity.

Understanding the Trade-offs

While highly effective, an internal mixer is not a universal solution. Understanding its limitations is key to making an informed decision.

Initial Cost and Complexity

These are sophisticated machines with complex mechanical, hydraulic, and cooling systems. The initial capital investment and ongoing maintenance costs are significantly higher than for simpler open mills.

Batch Processing Nature

Internal mixers are fundamentally batch-processing machines. This can create workflow bottlenecks if not properly integrated into a larger, continuous manufacturing line.

Cleaning and Changeover

The enclosed design that provides so many benefits can also make cleaning between different compound batches more difficult and time-consuming than with an open roll mill. This is a critical consideration for facilities that run many small, varied batches.

Making the Right Choice for Your Operation

Selecting the right mixing technology depends entirely on your production goals.

- If your primary focus is high-volume production and efficiency: The internal mixer's large capacity and short cycle times make it the definitive choice.

- If your primary focus is compound quality and consistency: The controlled environment of an internal mixer minimizes material loss and ensures a more uniform product.

- If your primary focus is operator safety and environmental control: The enclosed design is vastly superior, significantly reducing dust and chemical exposure.

Ultimately, choosing an internal mixer is a strategic investment in the control, consistency, and efficiency of your compounding process.

Summary Table:

| Feature | Internal Mixer | Open Mill |

|---|---|---|

| Process | Enclosed, batch | Open, continuous |

| Capacity & Speed | High volume, fast | Lower volume, slower |

| Quality & Consistency | High (minimized material loss) | Lower (potential for dust loss) |

| Safety & Environment | Excellent (contained dust/fumes) | Lower (exposure to dust/fumes) |

| Cost & Maintenance | Higher initial and ongoing cost | Lower initial and ongoing cost |

| Cleaning/Changeover | More complex and time-consuming | Simpler and faster |

Ready to enhance your compounding process with precision and efficiency?

At KINTEK, we specialize in providing robust laboratory equipment, including internal mixers, to meet the demanding needs of rubber and plastic production. Our solutions are designed to deliver the superior quality, consistency, and safety your operation requires.

Let's discuss how an internal mixer can transform your production line. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- Why is a rotary mechanical homogenizer used for extended periods for forsterite-spinel? Achieve Peak Ceramic Uniformity

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- What function does a high-speed rotor-stator homogenizer perform in biomass processing? Optimize Structural Disruption

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process