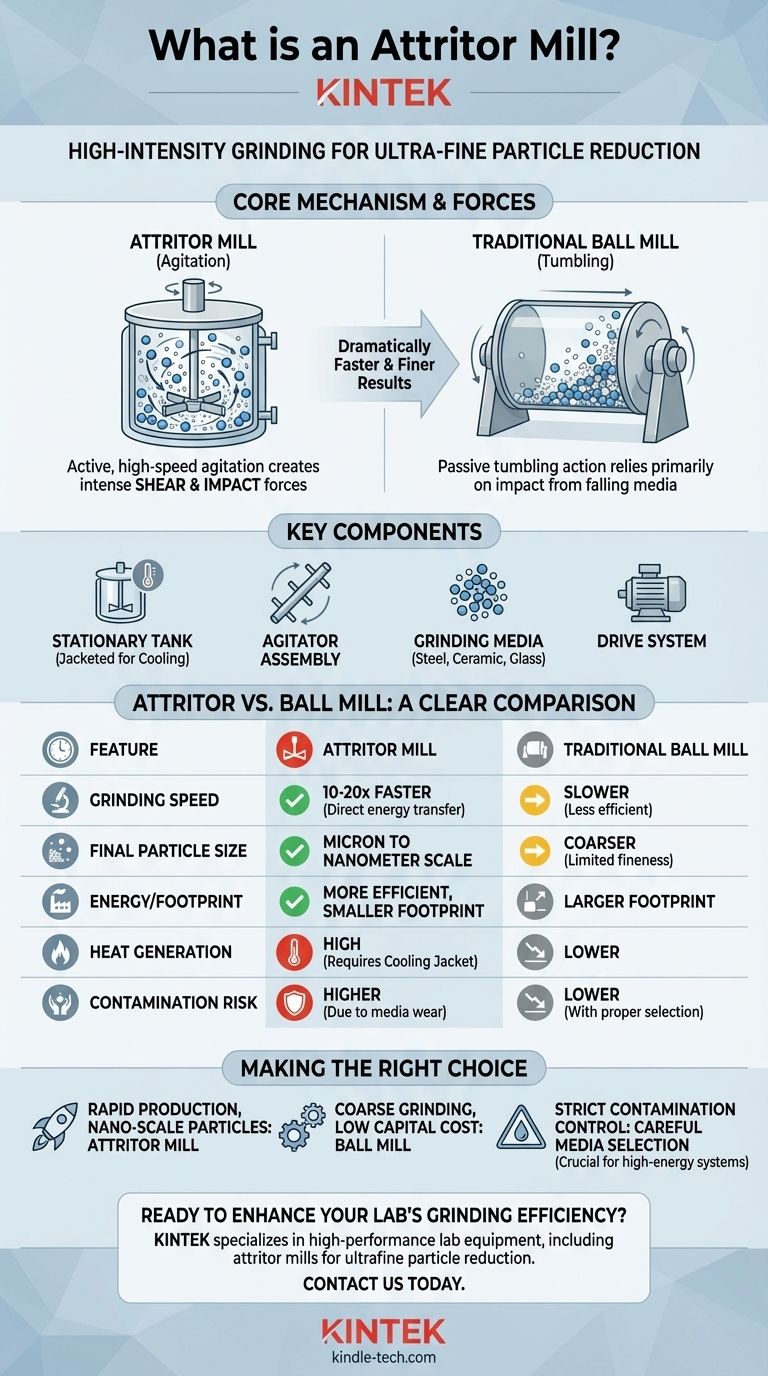

In essence, an attritor mill is a high-intensity grinding mill that achieves rapid and fine particle size reduction. Unlike a traditional ball mill that tumbles material in a rotating drum, an attritor uses a central, powered agitator shaft with arms to stir a stationary tank filled with grinding media and the material slurry. This agitated media action is significantly more energetic and efficient.

The critical difference is the mechanism: an attritor mill actively and violently agitates grinding media to create intense shear and impact forces. This fundamental design shift makes it dramatically faster and more effective at producing ultra-fine particles compared to the passive tumbling action of a ball mill.

How an Attritor Mill Achieves Superior Grinding

To understand why attritors are so effective, we must look beyond the simple act of grinding and focus on the specific forces they generate.

The Core Mechanism: Agitation vs. Tumbling

A traditional ball mill works by lifting grinding media and material along the wall of a rotating cylinder and allowing it to cascade or fall back down. The grinding is primarily done by the impact of the falling media.

An attritor mill, however, keeps the tank stationary. A central agitator shaft spins at high speed, creating a vortex and forcing the grinding media to move chaotically. This is a much more direct and efficient way to transfer energy.

The Power of Shear and Impact Forces

The agitator's action imparts kinetic energy to the thousands of grinding beads, creating two primary grinding forces:

- Impact: Grinding media collides at high velocity, crushing the material particles trapped between them.

- Shear: Grinding media slides and spins past one another at different speeds, creating intense shearing forces that rip particles apart.

This combination of forces is what allows attritor mills to reduce particles down to the micron and even nanometer scale far more quickly than other methods.

Key Components of the System

An attritor mill system is straightforward in its concept:

- Stationary Tank: A vessel, often jacketed for temperature control, holds the material slurry and grinding media.

- Agitator Assembly: A central rotating shaft fitted with arms or pins, which is the heart of the machine.

- Grinding Media: Small, hard beads typically made of steel, ceramic (like zirconia or alumina), or glass.

- Drive System: A powerful motor that turns the agitator at a precisely controlled speed.

Attritor vs. Ball Mill: A Clear Comparison

For professionals deciding on a milling technology, the comparison often comes down to the attritor and the more traditional ball mill. The differences are stark.

Speed and Efficiency

The attritor is fundamentally a more efficient machine. Because energy is transferred directly from the agitator to the media, grinding times can be 10 to 20 times faster than a comparable ball mill, where much of the energy is wasted simply lifting the entire charge.

Final Particle Size

The high-intensity shear and impact forces allow attritors to achieve significantly finer particle dispersions. While ball mills are excellent for coarse grinding, attritors excel at producing particles in the single-digit micron, sub-micron, and nano-scale ranges.

Energy Consumption and Footprint

For a given output, an attritor mill is often more energy-efficient and has a smaller physical footprint. The process is concentrated in a smaller, more intensely worked volume, requiring less factory floor space.

Understanding the Trade-offs and Considerations

While powerful, the attritor mill's high-energy nature introduces specific challenges that must be managed for successful operation.

Managing Heat Generation

The immense energy put into the system generates significant heat. Unchecked, this heat can damage the product or alter its chemical properties. Therefore, most attritors require a jacketed tank connected to a cooling system to maintain a stable processing temperature.

The Risk of Media Wear and Contamination

The high-velocity collisions can cause both the grinding media and the agitator arms to wear down over time. This wear introduces minute amounts of the media or agitator material into the product, which can be a critical issue in high-purity applications like pharmaceuticals or electronics.

Selecting the right material for the media and wear parts (e.g., hardened steel, tungsten carbide, or ceramics) is crucial to minimize contamination.

Operational Complexity

While conceptually simple, optimizing an attritor process requires careful control of variables like agitator speed, media size and loading, slurry viscosity, and temperature. It is a more technically demanding process than running a basic ball mill.

Making the Right Choice for Your Goal

The decision between milling technologies is not about which is "better" in a vacuum, but which is the correct tool for your specific objective.

- If your primary focus is rapid production and achieving nano-scale particles: The attritor mill is the superior choice due to its high-energy efficiency and ability to generate intense shear forces.

- If your primary focus is coarse grinding of large, robust batches with low capital cost: A traditional ball mill remains a highly effective and economical solution.

- If your primary focus is preventing all product contamination: You must carefully select the material for your grinding media and agitator arms, regardless of the mill type, but the risk is heightened in high-energy systems.

Understanding the fundamental mechanism of any tool is the first step toward mastering your process and achieving the desired result.

Summary Table:

| Feature | Attritor Mill | Traditional Ball Mill |

|---|---|---|

| Mechanism | High-speed agitator stirs stationary media | Rotating drum tumbles media and material |

| Primary Forces | High shear and impact | Primarily impact from cascading media |

| Grinding Speed | 10-20x faster | Slower, less efficient energy transfer |

| Final Particle Size | Micron to nanometer scale | Coarser particles, limited fineness |

| Heat Generation | High (requires cooling jacket) | Lower |

| Contamination Risk | Higher due to media wear | Lower with proper media selection |

Ready to enhance your lab's grinding efficiency? KINTEK specializes in high-performance lab equipment, including attritor mills designed for rapid, ultrafine particle size reduction. Whether you're in pharmaceuticals, ceramics, or advanced materials, our solutions help you achieve precise results with superior speed and control. Contact us today to discuss your specific grinding needs and discover the right equipment for your laboratory!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the average speed of a ball mill? Optimize Grinding with Critical Speed Calculations

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding