At its core, biofuel production through pyrolysis is a thermochemical process that uses extreme heat in an oxygen-free environment to rapidly decompose biomass. This method breaks down materials like wood or agricultural waste into a mixture of solid char, gas, and a vapor. This vapor is then cooled and condensed into a dark, viscous liquid known as 'bio-crude' or 'pyrolysis oil,' which serves as an intermediate for creating finished biofuels.

Pyrolysis is not a single-step solution for creating fuel. It is the critical deconstruction phase that efficiently converts solid, raw biomass into a liquid intermediate, which must then undergo a separate upgrading process to become a stable, usable biofuel.

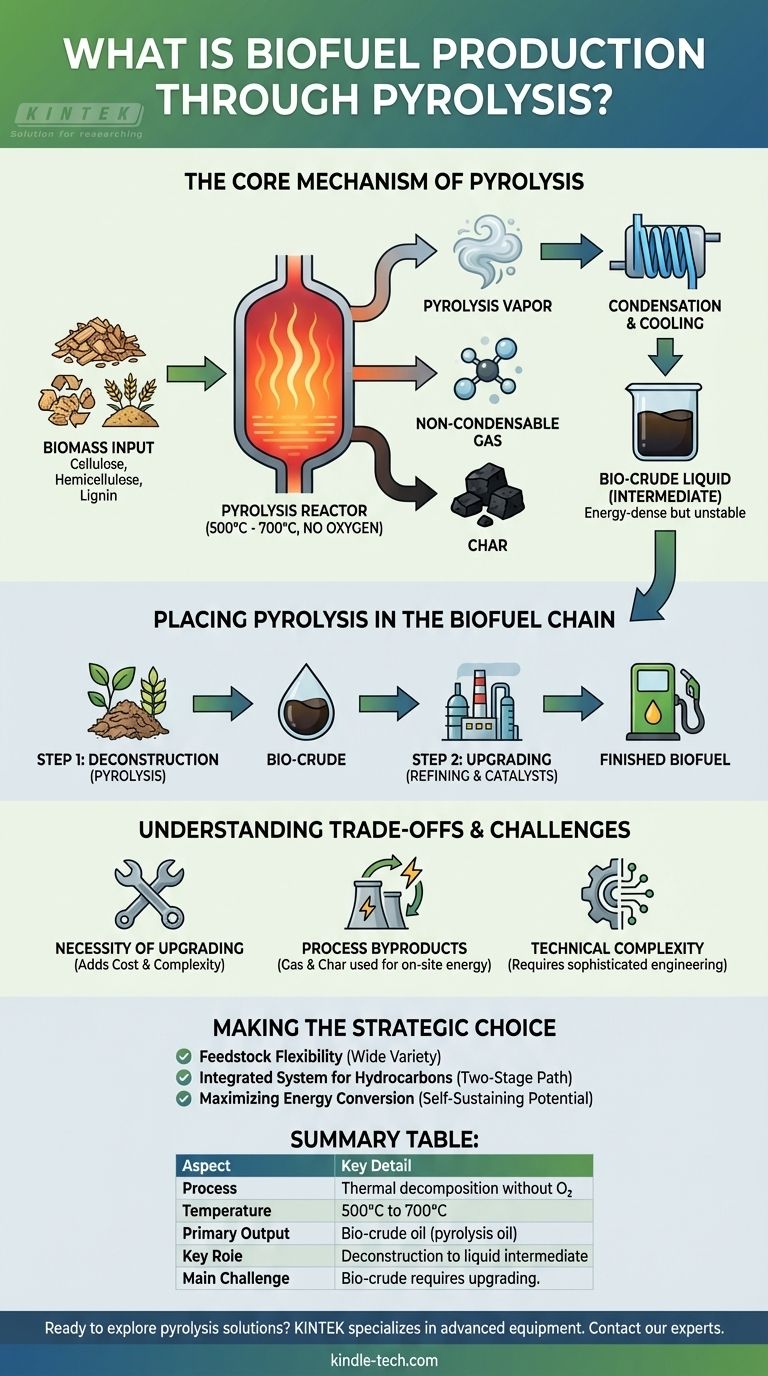

The Core Mechanism of Pyrolysis

To understand its role, you must first understand the fundamental mechanics of the process itself. Pyrolysis is a carefully controlled thermal breakdown, not a simple burning process.

The Key Ingredients: Biomass

The process begins with biomass, which primarily consists of three main structural components: cellulose, hemicellulose, and lignin. Pyrolysis is effective because it can break down this tough, rigid plant matter that other processes might struggle with.

The High-Temperature, Zero-Oxygen Environment

Biomass is fed into a reactor and heated rapidly to temperatures between 500°C and 700°C. Crucially, this occurs in an environment with no oxygen. The absence of oxygen prevents combustion (burning) and instead forces the complex molecules within the biomass to thermally crack and break apart.

The Three Primary Outputs

This rapid thermal decomposition yields three distinct products:

- Pyrolysis Vapor: A hot mist of aerosolized organic compounds. This is the most valuable output for liquid biofuel production.

- Non-condensable Gas: Gases like carbon monoxide and methane that do not turn into a liquid upon cooling.

- Char: A solid, carbon-rich byproduct similar to charcoal.

From Vapor to Liquid Bio-Crude

The hot pyrolysis vapor is separated from the solid char and then rapidly cooled, or "quenched." This condensation process transforms the vapor into the liquid bio-crude oil. This bio-crude contains the bulk of the energy from the original biomass but in a dense, liquid form that is easier to transport and process further.

Placing Pyrolysis in the Biofuel Production Chain

Pyrolysis is just one piece of a larger, multi-step puzzle. Viewing it as a standalone technology is a common misconception. It fits into a well-defined production pathway.

Step 1: Deconstruction

Producing advanced biofuels requires breaking down the resilient structure of plant cell walls. Pyrolysis is a form of high-temperature deconstruction. It uses heat and pressure to achieve this breakdown, standing in contrast to low-temperature methods that might use biological catalysts like enzymes.

The Intermediate Product: Bio-Crude

It is essential to understand that the bio-crude from pyrolysis is not a finished fuel. It is an intermediate product—a building block. While it is an energy-dense liquid, it is often acidic, unstable, and chemically different from conventional crude oil.

Step 2: Upgrading

To transform the raw bio-crude into a finished product like renewable gasoline or diesel, it must be upgraded. This is a refining step where catalysts or other chemical processes are used to remove unwanted compounds (like oxygen), improve stability, and make the fuel compatible with existing engines and infrastructure.

Understanding the Trade-offs and Challenges

While powerful, the pyrolysis pathway is not without its complexities. Acknowledging these realities is key to a complete understanding.

The Necessity of Upgrading

The single greatest challenge is that the bio-crude oil is not a "drop-in" fuel. The mandatory upgrading step adds significant cost and complexity to the overall production chain. Without it, the output of pyrolysis has very limited direct use.

Process Byproducts

An efficient pyrolysis operation must find a valuable use for its byproducts. The non-condensable gases and solid char are often burned on-site to generate the heat required to run the pyrolysis reactor itself, which improves the overall energy balance of the facility.

Technical Complexity

Operating a high-temperature reactor and the subsequent upgrading facility requires sophisticated engineering and control systems. It is a more technically demanding path compared to simpler biological processes like fermentation for ethanol.

Making the Right Choice for Your Goal

Pyrolysis is a strategic choice in biofuel production, best suited for specific feedstocks and end-products.

- If your primary focus is feedstock flexibility: Pyrolysis is highly effective because it can process a wide variety of dry, non-food biomass, including wood, crop residues, and other cellulosic materials.

- If your primary focus is producing a direct hydrocarbon fuel: You must view pyrolysis and upgrading as an integrated, two-stage system, as the raw bio-crude is unsuitable for direct use as a transport fuel.

- If your primary focus is maximizing energy conversion: The ability to use the gas and char byproducts to power the process makes pyrolysis a potentially self-sustaining and efficient pathway for converting biomass energy into a liquid form.

Ultimately, pyrolysis is a powerful and rapid deconstruction technology that unlocks the energy stored in tough biomass, creating a liquid intermediate on the journey to a finished biofuel.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Thermal decomposition of biomass without oxygen |

| Temperature | 500°C to 700°C |

| Primary Output | Bio-crude oil (pyrolysis oil) |

| Key Role | Deconstruction phase to create a liquid intermediate |

| Main Challenge | Bio-crude requires separate upgrading to become usable fuel |

Ready to explore pyrolysis solutions for your biofuel research or production? KINTEK specializes in advanced laboratory equipment and consumables for biomass conversion and analysis. Our precise heating systems and reactors can help you optimize your pyrolysis process. Contact our experts today to discuss how we can support your laboratory's journey in creating sustainable biofuels.

Visual Guide

Related Products

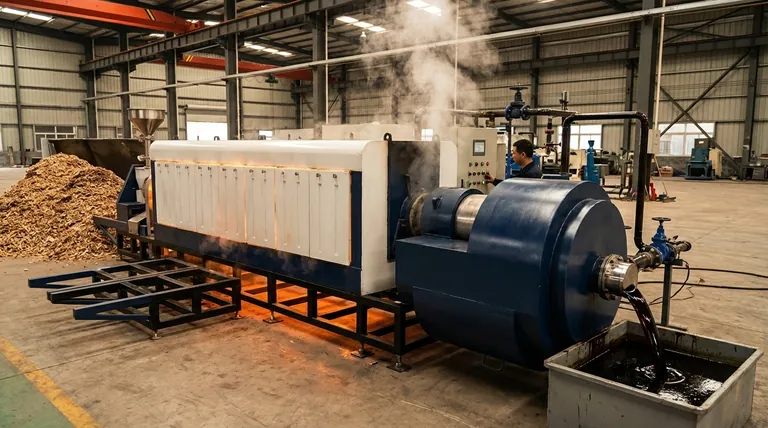

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is the calcining zone in the kiln? The Key to Efficient Chemical Transformation

- Which fuel is produced by pyrolysis process? Unlock a Trio of Valuable Energy Products

- What is a carbon regeneration kiln? Reuse Spent Carbon to Cut Costs & Waste

- What is pyrolysis of lignocellulosic materials? Converting Biomass into Bio-oil, Bio-char, and Syngas

- What are the conditions for calcination reactions? Mastering Temperature and Atmosphere Control

- What is the temperature of a rotary kiln? It's a Controlled Thermal Journey, Not a Single Number

- What is the energy efficiency of biomass? Understanding the 20-40% Range for Power Generation

- How do rotary kilns work? A Guide to Industrial Heating & Material Processing