In metallurgy, carburizing is a heat treatment process used to diffuse carbon into the surface of low-carbon steel components. It is the foundational step in most case hardening procedures, creating a surface layer with a higher carbon content. This enriched surface can then be hardened through quenching, resulting in a finished part that has an exceptionally hard, wear-resistant exterior and a tough, ductile interior.

Carburizing does not, by itself, make the steel hard. Instead, it changes the chemical composition of the surface, creating a "case" that has the potential to be hardened. The final hardness is only achieved after a subsequent rapid cooling process called quenching.

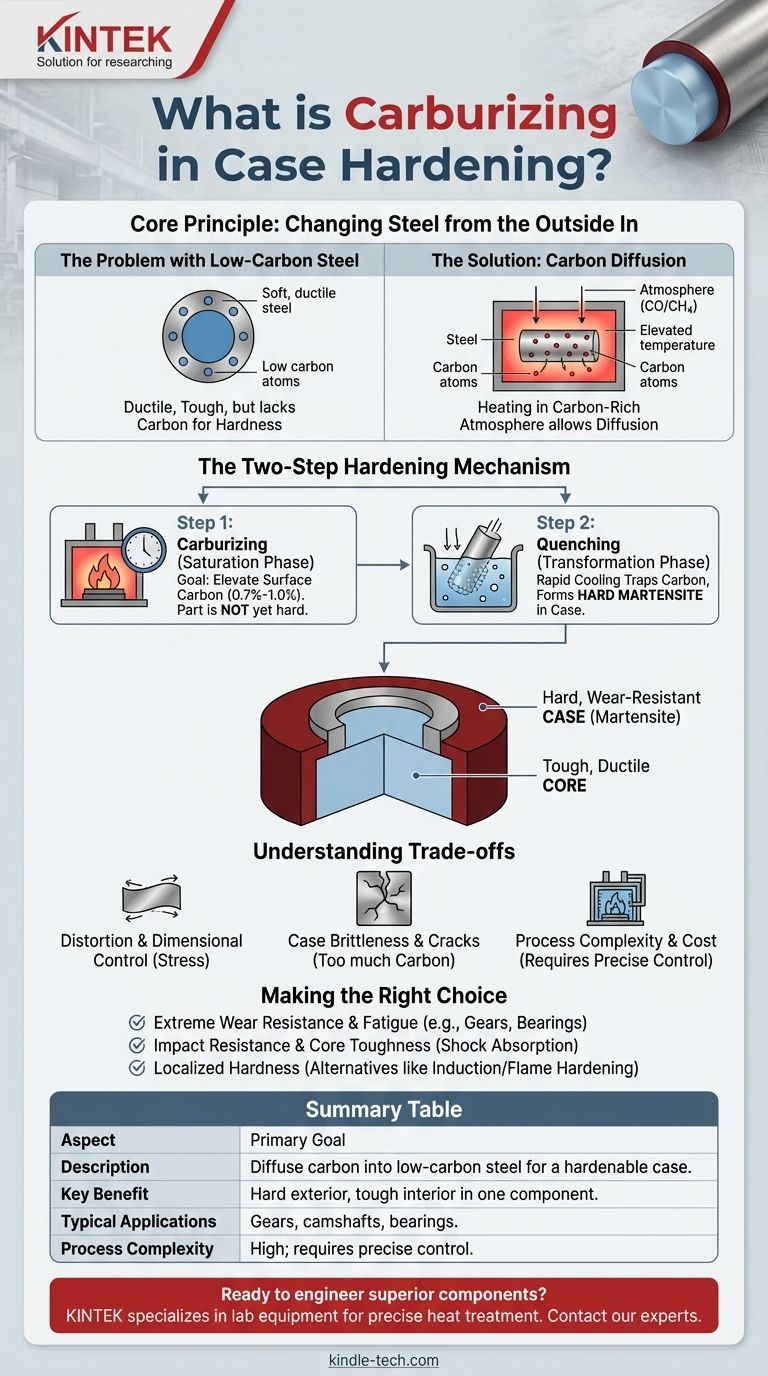

The Core Principle: Changing Steel from the Outside In

Carburizing solves a fundamental material engineering problem: the trade-off between hardness and toughness. By selectively modifying only the surface, it creates a composite material with the best properties of two different steels.

The Problem with Low-Carbon Steel

Low-carbon steels (typically with less than 0.3% carbon) are valued for their ductility, toughness, and excellent formability. However, they lack sufficient carbon to be significantly hardened through heat treatment. They can't form the hard martensitic structure required for high wear resistance.

The Solution: Carbon Diffusion

Carburizing overcomes this limitation by heating the low-carbon steel component in a controlled, carbon-rich atmosphere. At elevated temperatures (typically 1550-1750°F or 840-950°C), the steel's crystal structure opens up, and carbon atoms from the surrounding atmosphere are able to migrate, or diffuse, into the surface.

Controlling the Case Depth

The depth of this carbon-enriched layer, known as the case depth, is a critical design parameter. It is controlled primarily by two factors: temperature and time. Higher temperatures and longer exposure times allow carbon to penetrate deeper into the material.

The Two-Step Hardening Mechanism

Achieving the final desired properties is a distinct two-step process. Mistaking carburizing for the complete hardening process is a common misunderstanding.

Step 1: Carburizing (The Saturation Phase)

This is the diffusion stage. The steel part "soaks" at a high temperature in an atmosphere containing a source of carbon, such as carbon monoxide (CO) or methane (CH4). The goal is to elevate the surface carbon content to a target level, often between 0.7% and 1.0%. After this step, the part is compositionally different, but it is not yet hard.

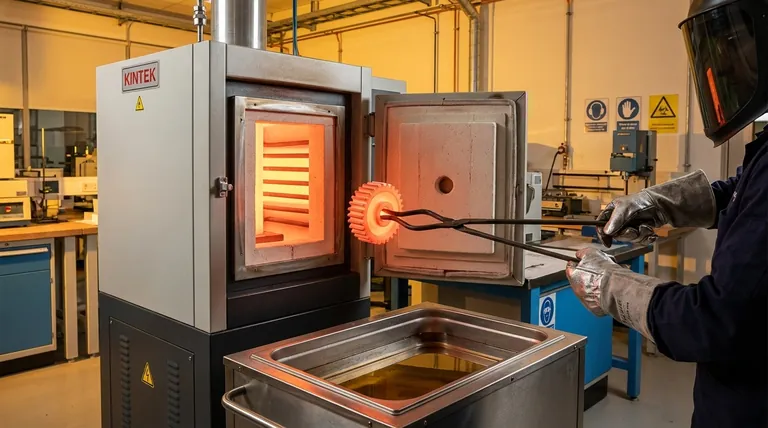

Step 2: Quenching (The Transformation Phase)

Immediately after carburizing or after a separate reheating step, the part is rapidly cooled, or quenched, typically in oil, water, or polymer. This rapid cooling traps the diffused carbon atoms within the steel's crystal lattice, forcing the formation of a very hard, brittle microstructure called martensite in the high-carbon case. The low-carbon core does not have enough carbon to form significant martensite, so it remains soft and tough.

Understanding the Trade-offs

While powerful, carburizing is a complex process with inherent challenges that must be managed for successful application.

Distortion and Dimensional Control

The intense thermal cycle of heating and rapid quenching introduces significant stress into the material. This can cause components to warp, shrink, or expand, requiring careful process control and often necessitating post-hardening grinding or machining to meet tight tolerances.

Case Brittleness and Grinding Cracks

If the carbon content in the case becomes too high or the case is too deep, the surface can become excessively brittle and prone to cracking under load or during final grinding operations. There is a fine balance between achieving maximum wear resistance and maintaining sufficient surface toughness.

Process Complexity and Cost

Atmosphere carburizing requires sophisticated furnace equipment with precise temperature and gas composition controls to manage the carbon potential of the atmosphere. This complexity makes it a more costly process compared to simpler surface hardening methods like induction hardening, especially for low-volume production.

Making the Right Choice for Your Application

Selecting carburizing depends entirely on the mechanical demands placed on the component.

- If your primary focus is extreme wear resistance and fatigue strength: Carburizing is the superior choice for high-load applications like transmission gears, camshafts, and rolling-element bearings.

- If your primary focus is impact resistance and core toughness: The process is ideal for parts that must withstand sudden shocks without fracturing, as the ductile core acts as a built-in shock absorber.

- If your component has a simple geometry and only needs localized hardness: Consider alternatives like induction or flame hardening, which can be faster and more cost-effective for specific surface areas.

Ultimately, carburizing is a powerful tool for engineering a single component that delivers two distinct, and often contradictory, sets of mechanical properties.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Goal | Diffuse carbon into the surface of low-carbon steel to create a hardenable "case." |

| Key Benefit | Combines a hard, wear-resistant exterior with a tough, ductile interior in a single component. |

| Typical Applications | Gears, camshafts, bearings, and other parts requiring high surface hardness and fatigue strength. |

| Process Complexity | High; requires precise control of temperature, time, and carbon-rich atmosphere. |

Ready to engineer components with superior wear resistance and core toughness?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise heat treatment processes like carburizing. Whether you are in R&D or quality control, our solutions help you achieve the exact material properties your applications demand.

Contact our experts today to discuss how we can support your laboratory's metallurgical needs.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer