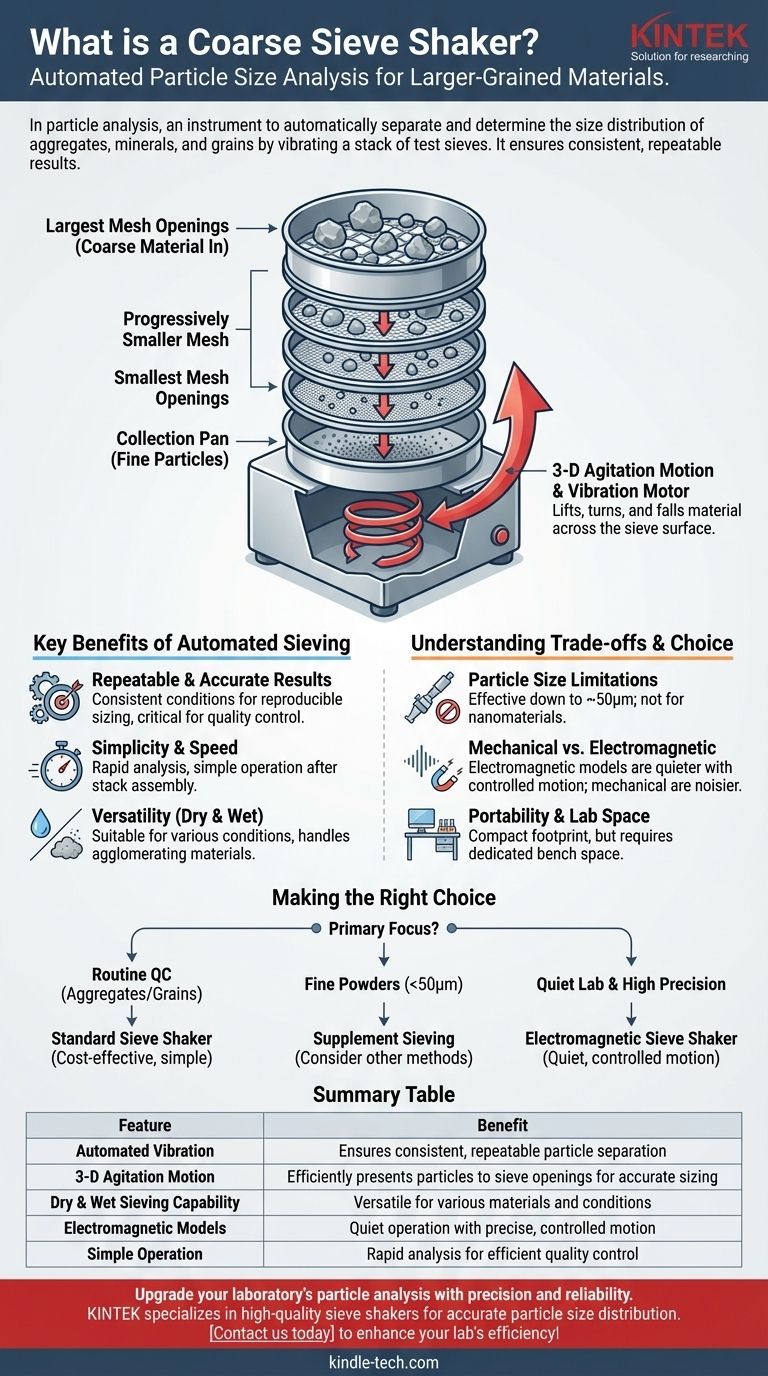

In particle analysis, a coarse sieve shaker is an instrument used to automatically separate and determine the particle size distribution of larger-grained materials. It operates by vibrating a stack of test sieves with progressively smaller mesh openings, allowing particles to be sorted by size. While the term "coarse" specifies the material being tested, the underlying machine is a standard sieve shaker configured for that purpose.

A coarse sieve shaker is not a fundamentally different machine, but rather the application of a standard sieve shaker to separate larger particles. Its core function is to provide a repeatable, automated method for determining the size composition of materials like aggregates, minerals, and grains.

How a Sieve Shaker Achieves Particle Separation

The effectiveness of a sieve shaker comes from its ability to methodically and consistently present every particle to the available sieve openings until the sample is fully sorted.

The Principle of Vibration

At the heart of the instrument is a vibration motor. This motor drives the base of the shaker, creating a powerful vibration that is transferred up through a vertically mounted stack of test sieves.

The Sieve Stack

Test sieves are arranged in a stack, with the sieve having the largest mesh openings at the top and the one with the smallest openings at the bottom. A solid pan is placed at the very bottom to collect the finest particles.

The 3-D Agitation Motion

Modern shakers, particularly electromagnetic models, employ a three-dimensional throwing or elliptical motion. This action lifts the material, turns it, and allows it to fall back across the entire surface of the sieve, ensuring particles are efficiently tested against the mesh openings.

Key Benefits of Automated Sieving

Using a sieve shaker provides significant advantages over manual methods, primarily focused on consistency, speed, and accuracy.

Repeatable and Accurate Results

The automated and controlled motion ensures that every sample is subjected to the exact same conditions. This leads to highly accurate and reproducible particle sizing results, which is critical for quality control.

Simplicity and Speed

Sieve shakers are designed for simple operation. Once the sieve stack is assembled and the sample is loaded, the process is rapid, allowing for quick separation and analysis.

Versatility for Different Conditions

Most sieve shakers are suitable for both dry sieving and wet sieving. Wet analysis is useful when dealing with materials that tend to agglomerate or are affected by static electricity, provided the material is not harmed by the liquid.

Understanding the Trade-offs

While highly effective, it's important to understand the operational context and limitations of sieve shakers.

Particle Size Limitations

A sieve shaker is excellent for analyzing coarse materials down to finer powders, with some models handling particles as small as 50-150 micrometers (µm). However, for extremely fine particles (nanomaterials), other methods like laser diffraction are required.

Mechanical vs. Electromagnetic Models

Traditional mechanical shakers get the job done but often have more moving parts and can be noisier. Electromagnetic sieve shakers are a quieter alternative, as they generate motion without moving parts, offering a more controlled and less disruptive testing environment.

Portability and Lab Space

Many modern sieve shakers are designed to be lightweight and portable. While they require minimal installation space, their footprint must still be considered for crowded laboratory benches.

Making the Right Choice for Your Goal

Selecting the right approach depends entirely on your material and your analytical objective.

- If your primary focus is routine quality control of aggregates or grains: A sieve shaker provides a cost-effective, simple, and highly repeatable method for process control.

- If your primary focus is analyzing fine powders below 50µm: You may need to supplement sieving with other particle analysis methods, as you are approaching the lower practical limit of the technology.

- If your primary focus is a quiet lab with high precision needs: An electromagnetic sieve shaker is a superior choice over a standard mechanical model due to its quiet operation and controlled motion.

Ultimately, understanding the principles of sieve shaking empowers you to select the right tool for achieving accurate and reliable particle size analysis.

Summary Table:

| Feature | Benefit |

|---|---|

| Automated Vibration | Ensures consistent, repeatable particle separation |

| 3-D Agitation Motion | Efficiently presents particles to sieve openings for accurate sizing |

| Dry & Wet Sieving Capability | Versatile for various materials and conditions |

| Electromagnetic Models | Quiet operation with precise, controlled motion |

| Simple Operation | Rapid analysis for efficient quality control |

Upgrade your laboratory's particle analysis with precision and reliability. KINTEK specializes in high-quality sieve shakers and lab equipment designed for accurate particle size distribution. Whether you're analyzing aggregates, minerals, or grains, our solutions ensure repeatable results and streamline your quality control processes. Contact us today to find the perfect sieve shaker for your needs and enhance your lab's efficiency!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials