At its core, copper foam is an advanced material used where a unique combination of high thermal conductivity, electrical conductivity, and a massive surface area is required. Its primary applications are in high-performance thermal management, such as heat exchangers, and as a functional component in energy systems, including battery electrodes and catalyst supports.

The true value of copper foam lies not in the copper itself, but in its three-dimensional, open-cell structure. This structure combines copper's inherent conductivity with the benefits of a vast, porous network, creating a material that solves problems solid copper cannot.

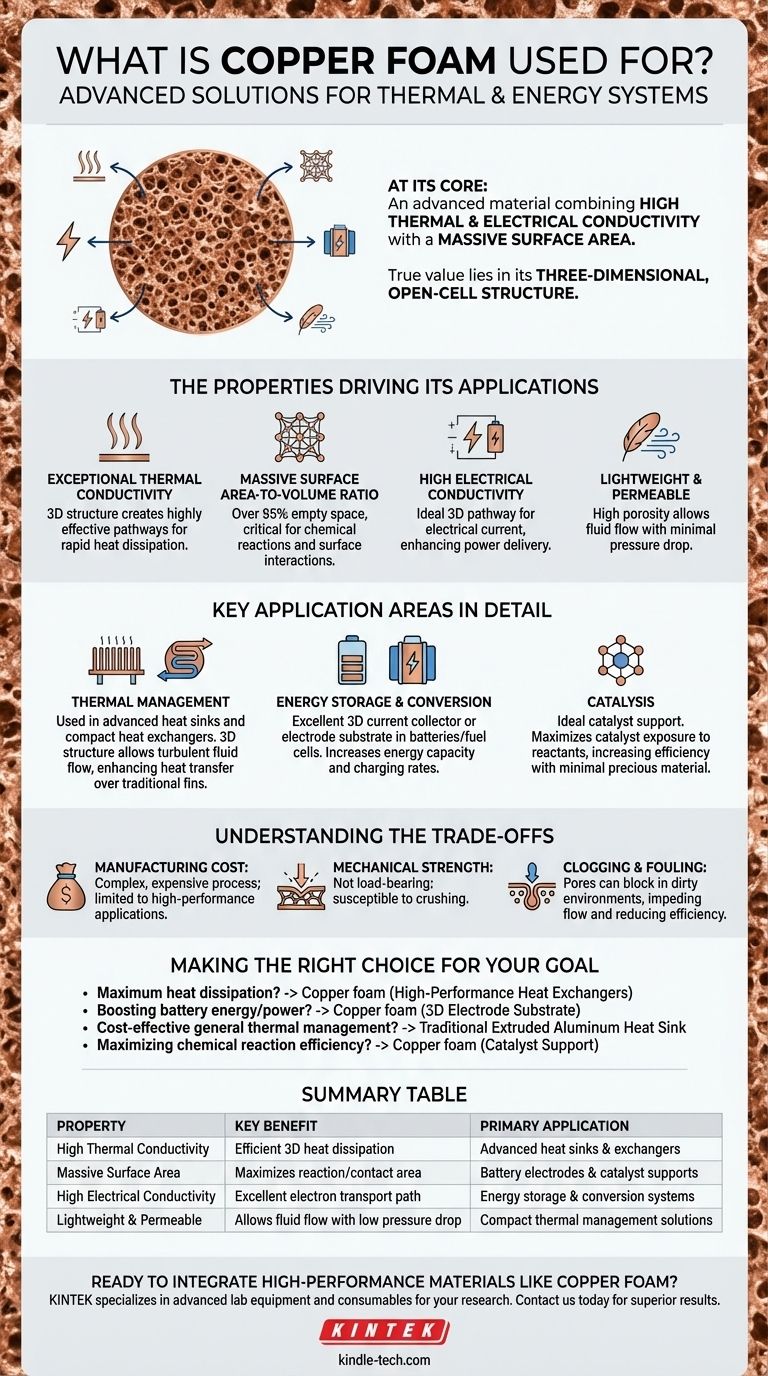

The Properties Driving Its Applications

To understand where to use copper foam, you must first understand its fundamental characteristics. Its applications are a direct result of its unique physical properties.

Exceptional Thermal Conductivity

Copper is one of the best thermal conductors among common metals. The interconnected metal ligaments in the foam create a highly effective, three-dimensional pathway for heat to move away from a source and dissipate quickly.

Massive Surface Area-to-Volume Ratio

The foam's open-cell structure, which can be over 95% empty space, creates an incredibly large surface area within a small volume. This is critical for any application involving chemical reactions or surface interactions.

High Electrical Conductivity

As it is made of pure copper, the foam maintains excellent electrical conductivity throughout its structure. This makes it an ideal pathway for electrical current, not just heat.

Lightweight and Permeable

Despite its metal composition, copper foam is extremely lightweight due to its high porosity. Its open-pore network also allows fluids (like air or coolants) to flow through it with minimal pressure drop, a key advantage over dense materials.

Key Application Areas in Detail

These properties translate directly into several high-value industrial and scientific uses.

Thermal Management

This is copper foam's most common application. It is used in advanced heat sinks and compact heat exchangers. The 3D structure allows for turbulent fluid flow, which disrupts the thermal boundary layer and enhances heat transfer far more efficiently than traditional 2D fins.

Energy Storage and Conversion

In batteries and fuel cells, copper foam serves as an excellent 3D current collector or electrode substrate. Its high surface area allows more active material to be loaded, increasing the battery's energy capacity. The continuous conductive network ensures efficient electron transport, improving power delivery and charging rates.

Catalysis

The vast surface area makes copper foam an ideal catalyst support. A thin, and often expensive, catalytic material (like platinum) can be coated onto the foam's surface. This maximizes the catalyst's exposure to reactants, increasing reaction efficiency while minimizing the amount of precious material needed.

Understanding the Trade-offs

No material is perfect. Acknowledging copper foam's limitations is critical for proper design and application.

Manufacturing Cost

Producing high-quality, uniform copper foam is a complex and expensive process compared to machining solid copper or extruding aluminum fins. This often limits its use to high-performance or specialized applications where cost is a secondary concern.

Mechanical Strength

While providing some structure, copper foam is not designed for significant load-bearing. It is susceptible to damage from compression or impact, which can crush the pores and degrade its performance.

Clogging and Fouling

In dusty or dirty environments, the intricate network of pores that makes copper foam so effective can become clogged. This blockage can impede fluid flow and insulate the very surfaces meant to transfer heat, reducing overall efficiency over time.

Making the Right Choice for Your Goal

Selecting copper foam depends entirely on the specific performance you need to achieve.

- If your primary focus is maximum heat dissipation in a compact, weight-sensitive device: Copper foam is an excellent candidate for a high-performance heat exchanger or heat sink.

- If your primary focus is boosting the energy density and power of a battery: Consider using copper foam as a 3D electrode substrate to improve ion and electron transport.

- If your primary focus is building a cost-effective system for general thermal management: A traditional extruded aluminum heat sink will almost always be the more economical solution.

- If your primary focus is maximizing the efficiency of a chemical reaction: Using copper foam as a catalyst support can dramatically improve performance by increasing the active surface area.

By understanding these core principles, you can leverage copper foam not just as a material, but as a strategic design solution.

Summary Table:

| Property | Key Benefit | Primary Application |

|---|---|---|

| High Thermal Conductivity | Efficient 3D heat dissipation | Advanced heat sinks & exchangers |

| Massive Surface Area | Maximizes reaction/contact area | Battery electrodes & catalyst supports |

| High Electrical Conductivity | Excellent electron transport path | Energy storage & conversion systems |

| Lightweight & Permeable | Allows fluid flow with low pressure drop | Compact thermal management solutions |

Ready to integrate high-performance materials like copper foam into your lab's projects? KINTEK specializes in providing advanced lab equipment and consumables tailored to your research and development needs. Whether you're working on next-generation thermal management systems or innovative energy storage solutions, our expertise ensures you have the right tools for success. Contact us today to discuss how we can support your laboratory's specific requirements and help you achieve superior results.

Visual Guide

Related Products

- Copper Foam

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What are the characteristics of copper foam? Unlock High-Performance Thermal and Electrical Solutions

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols

- What are the advantages of nickel foam? Unlock Superior Performance in Energy & Catalysis

- Is copper foam safe? Discover the facts about its antimicrobial and cooling benefits

- How do you transfer graphene from copper? A Step-by-Step Guide to Preserving Pristine Quality

- Is metal foam expensive? Unpacking the High Cost of Advanced Materials

- How to make nickel foam? A Guide to the Templating and Electroplating Process

- How do you make copper foam? A Step-by-Step Guide to Creating Porous Metal Structures