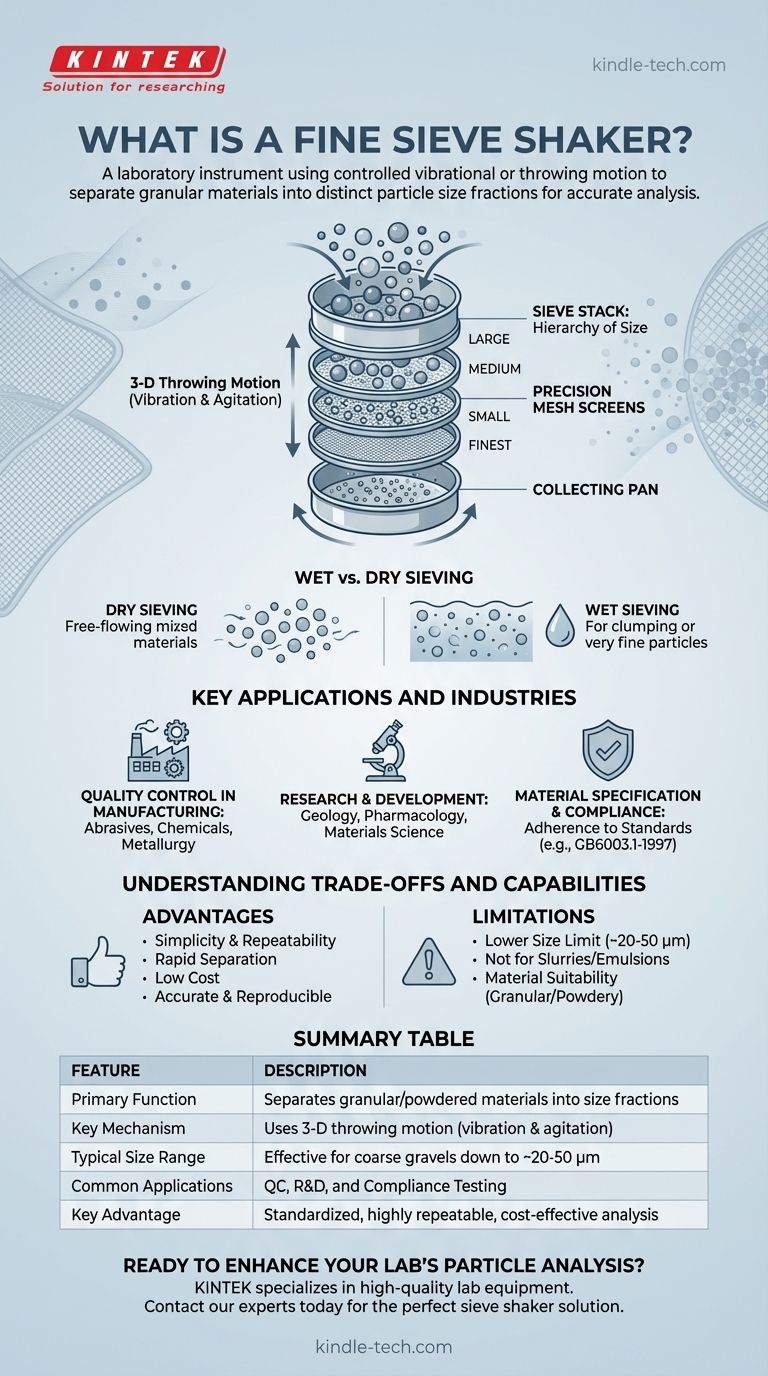

A fine sieve shaker is a laboratory instrument that uses a controlled vibrational or throwing motion to separate granular or powdered materials into distinct particle size fractions. It operates by agitating a stacked column of test sieves, each with a precisely sized mesh, allowing smaller particles to pass through to lower levels while retaining larger ones on top. This process provides an accurate determination of a material's particle size distribution.

While its function is simple—shaking particles through a series of screens—the true value of a sieve shaker lies in its ability to provide standardized, repeatable, and accurate particle size analysis. This makes it an essential tool for quality control, research, and compliance across numerous industries where particle characteristics define material performance.

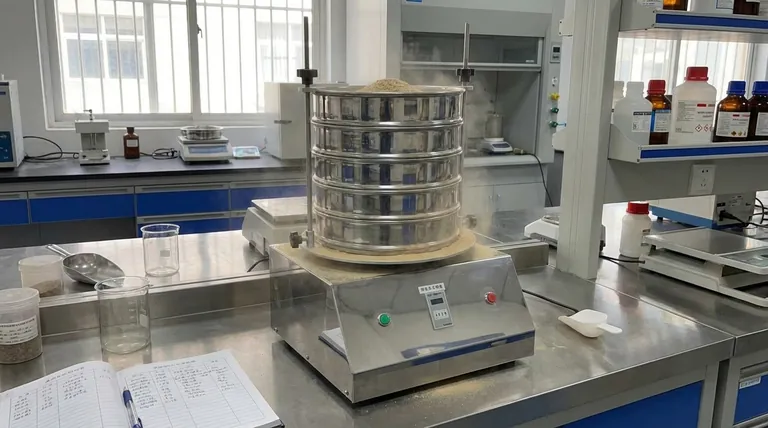

How a Sieve Shaker Achieves Particle Separation

A sieve shaker’s effectiveness comes from a combination of a precise mechanical motion and a standardized set of analytical tools. Understanding this process is key to appreciating its role in materials science.

The Core Mechanism: Vibration and Agitation

The heart of the instrument is a powerful motor that generates a consistent, repeatable motion. This is often a 3-D throwing motion, which combines a horizontal circular movement with a vertical tapping impulse.

This complex agitation ensures that all particles in the sample are repeatedly presented to the sieve openings from different angles, preventing clogging and guaranteeing that a particle has every opportunity to pass through an aperture if it is small enough.

The Sieve Stack: A Hierarchy of Size

Analysis is performed using a stack of test sieves. These are nested frames containing a wire mesh or perforated plate screen with openings of a specific, uniform size.

The sieves are stacked in order of decreasing aperture size, with the sieve having the largest openings on top and the one with the smallest openings at the bottom. A solid pan is placed at the very bottom to collect the finest particles.

Wet vs. Dry Sieving

Sieve shakers can be used for both dry and wet sieving. Dry sieving is the most common method for materials that flow freely.

Wet sieving is used when a material is prone to clumping, static electricity, or contains very fine particles that might otherwise agglomerate. A liquid (usually water) is used to disperse the particles and carry them through the sieves. This is only suitable if the liquid does not chemically or physically alter the material being tested.

Key Applications and Industries

The ability to accurately measure particle size is critical in many fields. Sieve shakers are foundational instruments for ensuring materials meet specifications.

Quality Control in Manufacturing

In industries like abrasives, chemicals, and metallurgy, particle size directly impacts product performance, consistency, and safety. Sieve shakers are used in quality inspection rooms to verify that raw materials and finished products meet required size distributions.

Research and Development

Scientists in geology, pharmacology, and materials science use sieve shakers for fundamental characterization. For instance, in pharmacopoeia, particle size affects a drug's dissolution rate and bioavailability. In geology, it is used to analyze soil and sediment composition.

Material Specification and Compliance

Many industries adhere to strict standards for particle sizing. Sieve shakers use screens that meet official standards, such as GB6003.1-1997 for woven wire mesh, ensuring that analysis is accurate, reproducible, and compliant with regulatory requirements.

Understanding the Trade-offs and Capabilities

While powerful, a sieve shaker is not a universal solution. Understanding its advantages and limitations is crucial for selecting the right analytical method.

The Primary Advantage: Simplicity and Repeatability

The main strengths of a sieve shaker are its simplicity of operation, rapid separation, and low cost compared to more complex methods. It requires minimal installation space and provides highly accurate and reproducible results, making it ideal for routine testing.

The Lower Size Limit

Sieve shaking is exceptionally effective for materials from coarse gravels down to fine powders. However, it has a practical lower limit, typically around 20 to 50 micrometers (µm). Below this threshold, physical forces can cause particles to stick to the mesh, making separation inefficient.

Material Suitability

This method is designed for granular and powdery materials. It is not suitable for slurries, emulsions, or materials that would be damaged by the mechanical shaking action. The choice between wet and dry sieving must be made based on the material's properties.

Is a Sieve Shaker the Right Tool for Your Analysis?

Choosing the right particle analysis method depends entirely on your material, the required precision, and your operational goals.

- If your primary focus is routine quality control for particles above 20µm: A sieve shaker offers a cost-effective, reliable, and highly repeatable solution for ensuring product consistency.

- If your primary focus is foundational research in geology, agriculture, or construction materials: A sieve shaker provides standardized and accurate data for characterizing granular materials according to established scientific methods.

- If your primary focus is analyzing extremely fine particles (sub-20µm) or complex emulsions: You will likely need to explore more advanced techniques like laser diffraction or dynamic light scattering, as sieving has practical limitations at these scales.

Ultimately, the sieve shaker remains a cornerstone of particle analysis due to its unmatched blend of simplicity, accuracy, and efficiency for a wide range of common materials.

Summary Table:

| Feature | Description |

|---|---|

| Primary Function | Separates granular/powdered materials into distinct particle size fractions. |

| Key Mechanism | Uses a 3-D throwing motion (vibration & agitation) to pass particles through a stack of test sieves. |

| Typical Size Range | Effective for particles from coarse gravels down to approximately 20-50 micrometers (µm). |

| Common Applications | Quality control (abrasives, chemicals), R&D (pharmacology, geology), and compliance testing. |

| Key Advantage | Provides standardized, highly repeatable, and cost-effective analysis with simple operation. |

Ready to enhance your lab's particle analysis with precision and reliability?

KINTEK specializes in high-quality lab equipment and consumables, including fine sieve shakers designed for accurate and repeatable results. Whether your focus is on rigorous quality control or foundational research, our solutions are built to meet your specific laboratory needs.

Contact our experts today to find the perfect sieve shaker for your application and ensure your materials meet the highest standards.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation