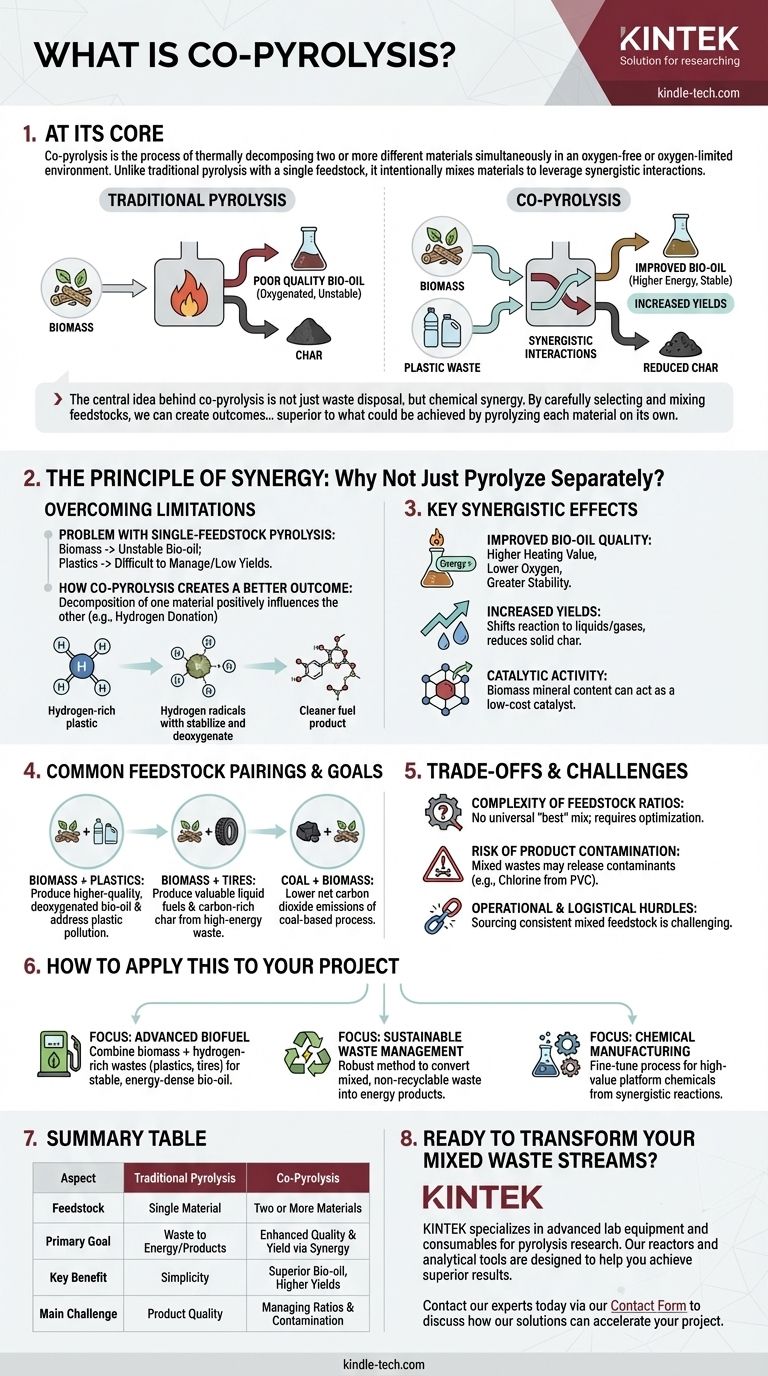

At its core, co-pyrolysis is the process of thermally decomposing two or more different materials simultaneously in an oxygen-free or oxygen-limited environment. Unlike traditional pyrolysis which uses a single feedstock, co-pyrolysis intentionally mixes distinct materials—such as biomass with plastic waste—to leverage synergistic interactions that improve the process and its final products.

The central idea behind co-pyrolysis is not just waste disposal, but chemical synergy. By carefully selecting and mixing feedstocks, we can create outcomes—such as higher-quality fuels or more valuable chemicals—that are superior to what could be achieved by pyrolyzing each material on its own.

The Principle of Synergy: Why Not Just Pyrolyze Separately?

The decision to mix feedstocks is a deliberate engineering choice aimed at overcoming the limitations inherent in using a single type of material.

The Problem with Single-Feedstock Pyrolysis

Pyrolyzing a single material like biomass often yields a liquid product (bio-oil) that is highly oxygenated, acidic, and unstable. This makes it a poor-quality fuel without significant and costly upgrading.

Conversely, pyrolyzing plastics can produce a high-energy oil, but the process can be difficult to manage, and some plastics (like PET) yield very little liquid fuel.

How Co-pyrolysis Creates a Better Outcome

Co-pyrolysis aims to create a whole that is greater than the sum of its parts. The decomposition of one material generates reactive chemical species that positively influence the decomposition of the other.

A primary example is the hydrogen donation mechanism. Hydrogen-rich materials like plastics break down and release hydrogen radicals, which then stabilize and deoxygenate the fragments from hydrogen-poor materials like biomass.

Key Synergistic Effects

This interaction leads to several measurable benefits:

- Improved Bio-oil Quality: The resulting liquid has a higher heating value, lower oxygen content, and greater stability, making it a more viable precursor to transportation fuels.

- Increased Yields: Synergy can shift reaction pathways to favor the production of liquids or specific gases, while reducing the formation of less-desirable solid char.

- Catalytic Activity: The inherent mineral or ash content in some types of biomass can act as a low-cost catalyst, promoting the breakdown of plastics at lower temperatures.

Common Feedstock Pairings and Their Goals

The choice of feedstock combination is driven by a specific technical or economic goal, most often related to waste valorization or fuel improvement.

Biomass and Plastics

This is the most widely studied combination. Agricultural residues, wood waste, or forestry byproducts are mixed with plastic waste (e.g., polyethylene, polypropylene). The primary goal is to produce a higher-quality, deoxygenated bio-oil for biofuel applications while simultaneously addressing plastic pollution.

Biomass and Tires

Scrap tires are a significant waste stream with high energy content. Co-pyrolyzing them with biomass can produce valuable liquid fuels and a solid carbon-rich char that has applications in manufacturing and as an adsorbent.

Coal and Biomass

In some industrial contexts, biomass is co-pyrolyzed or co-gasified with coal. The goal here is often environmental, using the carbon-neutral biomass to lower the net carbon dioxide emissions of the coal-based process.

Understanding the Trade-offs and Challenges

While powerful, co-pyrolysis is not a simple solution and introduces its own set of complexities that must be managed.

The Complexity of Feedstock Ratios

There is no universal "best" mix. The optimal ratio of feedstocks is highly specific to the materials used and the desired product. Finding this optimum requires significant empirical testing and characterization. An incorrect ratio can negate any synergistic effects or even hinder the process.

The Risk of Product Contamination

Using mixed, real-world waste streams introduces the risk of contaminants. For example, co-processing plastics like PVC (polyvinyl chloride) can release chlorine, forming corrosive hydrochloric acid in the reactor and contaminating the final products. This necessitates more robust and expensive downstream cleanup systems.

Operational and Logistical Hurdles

Sourcing a consistent and reliable supply of mixed feedstock can be a major logistical challenge. The variability in municipal solid waste, for instance, means the process must be robust enough to handle fluctuations in its input stream, which can affect product consistency.

How to Apply This to Your Project

Your strategy for using co-pyrolysis should be directly aligned with your end goal, as the process can be optimized for different outcomes.

- If your primary focus is advanced biofuel production: Use co-pyrolysis to combine biomass with hydrogen-rich wastes like plastics or tires to create a more stable and energy-dense bio-oil.

- If your primary focus is sustainable waste management: Leverage co-pyrolysis as a robust method to convert mixed, non-recyclable waste streams into energy products, reducing landfill burden.

- If your primary focus is chemical manufacturing: Fine-tune the process temperature, heating rate, and feedstock blend to selectively favor the production of high-value platform chemicals from the synergistic reactions.

Ultimately, co-pyrolysis transforms the challenge of mixed waste into an opportunity for creating value.

Summary Table:

| Aspect | Traditional Pyrolysis | Co-Pyrolysis |

|---|---|---|

| Feedstock | Single Material | Two or More Materials (e.g., Biomass + Plastic) |

| Primary Goal | Waste to Energy/Products | Enhanced Product Quality & Yield via Synergy |

| Key Benefit | Simplicity | Superior Bio-oil, Higher Yields, Waste Valorization |

| Main Challenge | Product Quality (e.g., Unstable Bio-oil) | Managing Feedstock Ratios & Potential Contamination |

Ready to transform your mixed waste streams into high-value products?

KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you are developing advanced biofuels, optimizing sustainable waste management, or producing high-value chemicals, our reactors and analytical tools are designed to help you achieve superior results through processes like co-pyrolysis.

Contact our experts today via our Contact Form to discuss how our solutions can accelerate your project and unlock the full potential of synergistic thermal conversion.

Visual Guide

Related Products

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What does a sputter coater do? Achieve Ultra-Thin, Uniform Coatings for Your Lab

- What temperature should a furnace run at? From Home Comfort to Industrial Processes

- What is the heating rate for slow and fast pyrolysis? Control Your Biomass Conversion Outcome

- What is the difference between RF and DC sputtering? Choose the Right Method for Your Material

- How does reactive sputtering work? Master Thin Film Deposition for Superior Coatings

- What is the use of furnace in a laboratory? Essential Tool for Material Transformation

- What are the four stages of sintering? A Guide to Precise Material Densification

- What are the properties of pyrolysis bio-oil? A Deep Dive into Its Unique Chemical Profile