One of the most significant disadvantages of the ball mill method is the high potential for contamination of the final product. This occurs as the grinding media and the internal lining of the mill wear down during operation, introducing unwanted material into the powder. Furthermore, the process is notoriously slow, which can be a major bottleneck in production environments.

While ball mills are highly effective for achieving very fine particle sizes, their primary drawbacks stem from a lack of precise control. This can lead to inconsistent particle sizes, potential product contamination, and changes to the material's fundamental structure.

Key Operational Limitations

A ball mill operates on the simple principle of impact and attrition, but this simplicity brings several inherent limitations that are critical to understand.

High Potential for Contamination

The constant tumbling and impact of the grinding media (the balls) against the mill's inner wall causes abrasion. Over time, particles from both the balls and the liner will chip off and mix with the material being milled. This can be a critical issue in applications requiring high purity, such as pharmaceuticals or certain electronics.

Inconsistent Particle Size

The process does not guarantee uniform particle size reduction. The result is often a highly polydisperse size distribution, meaning the final powder contains a wide range of particle sizes. For applications that depend on particle uniformity for performance, this can be a significant drawback.

Slow Processing Speed

Ball milling is a process of gradual size reduction. It can take many hours to achieve the desired fineness, making it unsuitable for high-throughput applications where processing speed is a primary concern. Its capacity is also often limited, restricting its use for large-scale production.

Ineffectiveness with Certain Materials

Ball mills are most effective on hard, brittle materials. They are largely unable to process materials that are soft, tacky, or fibrous. These materials tend to smear, agglomerate, or absorb the impact energy without fracturing, making the milling process inefficient or impossible.

Understanding the Trade-offs

Choosing a ball mill involves weighing its clear advantages against its significant drawbacks. The ideal use case is one where its strengths are essential and its weaknesses are manageable.

Fine Grinding vs. Purity and Speed

A ball mill's primary advantage is its ability to produce extremely fine powder, often with particle sizes of 10 microns or less. The trade-off is that achieving this comes at the cost of long processing times and the ever-present risk of contamination from media wear.

Enclosed System vs. Internal Contamination

The enclosed nature of a ball mill is excellent for processing toxic materials or maintaining sterility, as it contains the material safely. However, this creates a paradox: while the system is protected from external contaminants, it generates its own internal contaminants through mechanical wear.

Particle Reduction vs. Structural Integrity

The intense mechanical energy involved in high-energy ball milling can do more than just reduce particle size. It can alter the material's fundamental properties, sometimes rendering the powder partially amorphous. This means the original crystalline structure is disrupted, which can be an undesirable side effect for many materials.

Making the Right Choice for Your Application

Ultimately, the decision to use a ball mill depends entirely on your specific goals and material properties.

- If your primary focus is achieving the finest possible particle size with brittle materials: A ball mill is an excellent, cost-effective choice, but you must account for slow processing times.

- If your primary focus is maintaining absolute product purity: You must carefully select extremely hard, non-reactive grinding media or consider alternative milling technologies to avoid contamination.

- If your primary focus is high-throughput production: The slow speed and batch limitations of ball mills make them unsuitable; a continuous, higher-capacity milling system would be a better choice.

Understanding these core limitations is the key to deciding if a ball mill's advantages align with your specific material and production goals.

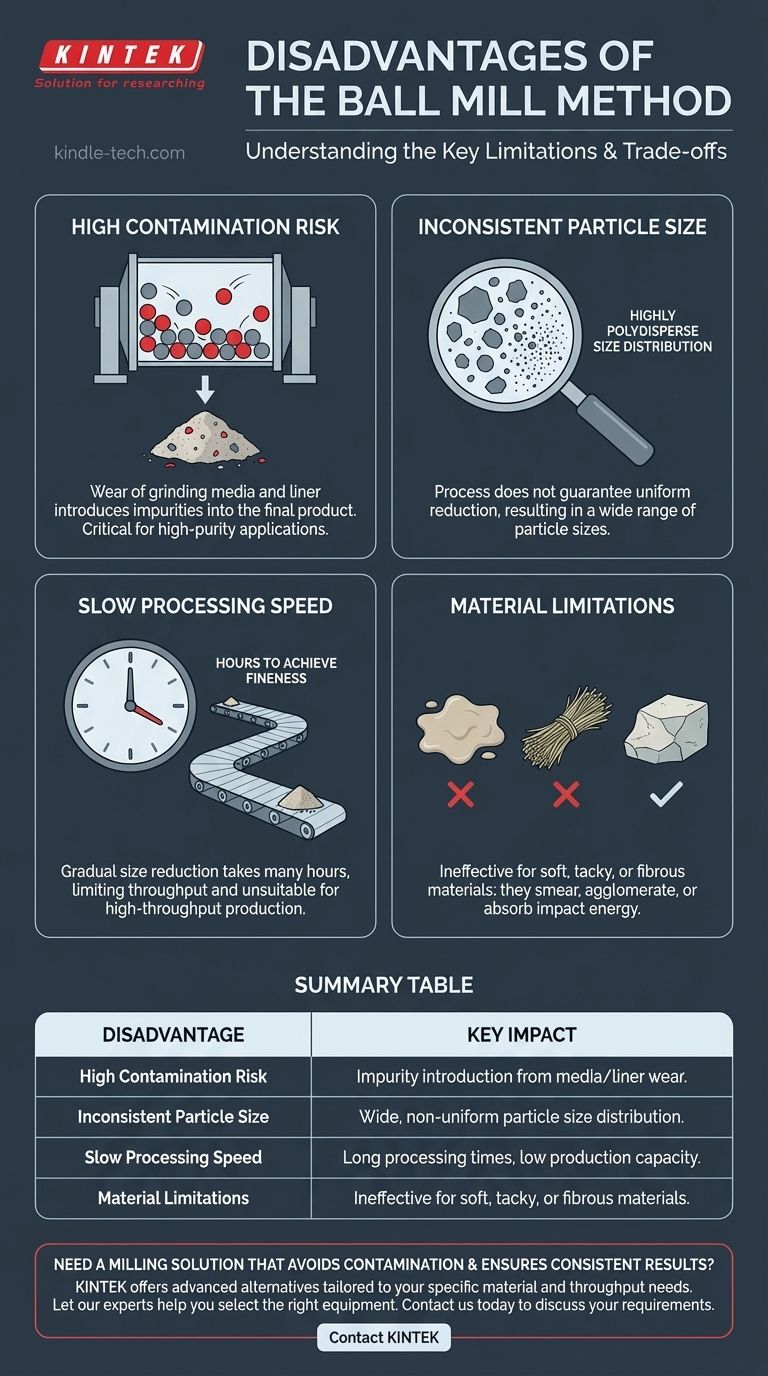

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Contamination Risk | Wear of grinding media and liner introduces impurities into the final product. |

| Inconsistent Particle Size | Results in a wide, non-uniform particle size distribution (polydisperse). |

| Slow Processing Speed | Takes hours to achieve fine powder, limiting throughput and production capacity. |

| Material Limitations | Ineffective for soft, tacky, or fibrous materials that do not fracture easily. |

Need a milling solution that avoids contamination and ensures consistent results?

While ball mills have their place, their limitations in purity, speed, and particle uniformity can hinder your production. KINTEK specializes in advanced lab equipment and consumables, offering alternatives tailored to your specific material and throughput needs—whether you require high-purity processing, faster grinding, or better particle size control.

Let our experts help you select the right equipment for your application. Contact us today to discuss your requirements and achieve superior milling performance.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling