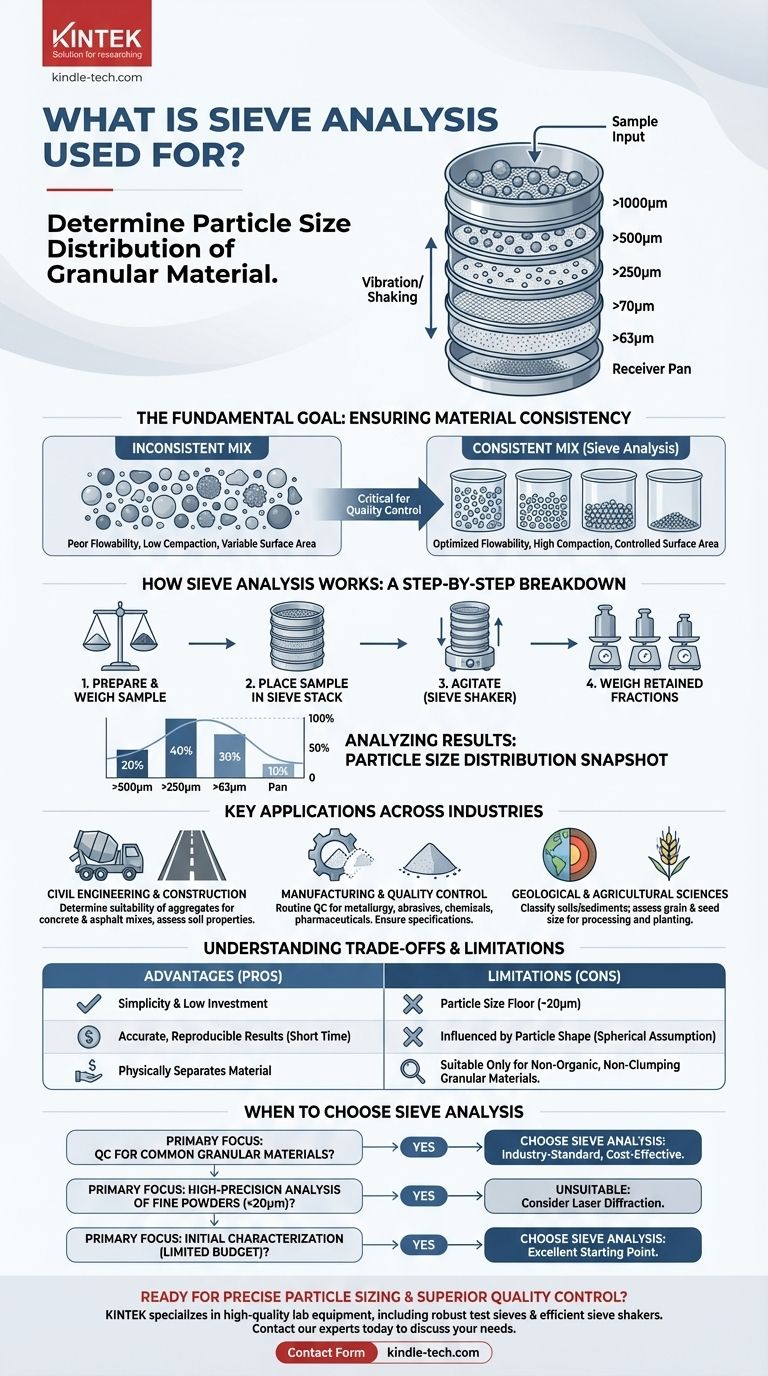

At its core, sieve analysis is used to determine the particle size distribution of a granular material. It is a foundational quality control and material characterization technique that works by physically separating particles into different size fractions using a stack of screens with progressively smaller mesh openings. This allows you to quantify the percentage of material within specific size ranges.

Sieve analysis moves beyond simple measurement; it is a critical process for verifying that a material's physical properties meet the precise specifications required for its end use, from the strength of concrete to the consistency of a manufactured powder.

The Fundamental Goal: Ensuring Material Consistency

To understand the use of sieve analysis, you must first understand the importance of particle size distribution. It is a primary factor that dictates the physical and chemical properties of a material.

What is Particle Size Distribution?

Particle size distribution refers to the statistical representation of the different particle sizes present in a given sample.

A material is rarely uniform. It is almost always a mix of larger and smaller particles. This distribution profile influences factors like flowability, compaction, surface area, and reaction rates.

Why This Measurement Matters

Knowing the particle size distribution is critical for quality control. It provides direct insight into whether a material from a production line is consistent and suitable for its intended purpose.

An incorrect distribution can lead to product failure, whether it's concrete that lacks strength or a chemical powder that clumps instead of dissolving smoothly.

How Sieve Analysis Works: A Step-by-Step Breakdown

The process is valued for its straightforward and mechanical nature, providing tangible, reproducible results.

The Core Equipment

The analysis relies on a stack of test sieves—wire mesh screens with precisely measured square openings—placed in a column.

The sieve with the largest openings is placed at the top, with each subsequent sieve below it having progressively smaller openings. A receiver pan is placed at the very bottom to collect the finest particles. This stack is often agitated by a sieve shaker for consistency.

The Sieving Process

First, a representative sample of the material is carefully weighed. The sample is then placed in the top sieve of the prepared stack.

The stack is agitated for a set period, allowing particles to pass through the mesh openings until they are retained by a sieve with openings smaller than their diameter.

Analyzing the Results

After shaking, the material retained on each sieve is weighed. The weight of each fraction is then calculated as a percentage of the total initial sample weight.

This data provides a clear "snapshot" of the particle size distribution, showing exactly what percentage of the material falls within each size range defined by the sieves.

Key Applications Across Industries

Sieve analysis is not limited to one field; its utility is widespread due to its reliability and simplicity.

Civil Engineering and Construction

This is one of the most common applications. The results are used to determine the suitability of aggregates like sand and crushed rock for concrete and asphalt mixes. The right particle distribution is essential for strength and durability.

It is also used for sizing screens for water production wells and assessing soil properties for geotechnical purposes.

Manufacturing and Quality Control

In manufacturing, sieve analysis is a routine quality control procedure for any process involving granular materials.

This includes industries like metallurgy, abrasives, chemicals, and pharmaceuticals. It ensures that powders and grains meet the specifications required for subsequent processing steps.

Geological and Agricultural Sciences

Geologists use sieve analysis to classify soils and sediments like clay, granite, and feldspar.

In agriculture, it is used to assess the size distribution of grains and seeds, which can be important for processing and planting.

Understanding the Trade-offs and Limitations

While powerful, sieve analysis is not a universal solution. Understanding its advantages and disadvantages is key to using it appropriately.

Key Advantages

The primary advantages of sieve analysis are its simplicity and low investment cost. The equipment is robust and the procedure is easy to learn and execute.

It provides accurate and reproducible results in a relatively short time. A unique benefit is that it physically separates the material, allowing for further examination of each size fraction.

Inherent Limitations

The most significant limitation is its particle size floor. Sieve analysis is generally effective for particles down to about 20 micrometers (μm). For finer powders or nanomaterials, other methods like laser diffraction are required.

The analysis is also influenced by particle shape. The method assumes particles are roughly spherical. Elongated or flat particles may pass through mesh openings end-on or clog the screen, skewing the results.

Finally, it is only suitable for non-organic, granular materials that do not clump or hold a static charge, which can prevent them from passing freely through the sieves.

When to Choose Sieve Analysis

Choosing the right particle analysis method depends entirely on your material and objectives.

- If your primary focus is quality control for common granular materials (sand, aggregate, grains): Sieve analysis is the industry-standard, most cost-effective, and reliable method.

- If your primary focus is high-precision analysis of very fine powders (<20µm): Sieve analysis is unsuitable, and you should consider advanced techniques like laser diffraction or dynamic light scattering.

- If your primary focus is initial material characterization with a limited budget: Sieve analysis provides an excellent and accessible starting point for understanding your material's physical properties.

Ultimately, sieve analysis provides a reliable, practical, and indispensable foundation for controlling the physical properties of a wide range of materials.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Use | Determines the particle size distribution of a granular material. |

| Key Industries | Civil Engineering, Manufacturing, Pharmaceuticals, Agriculture, Geology. |

| Key Equipment | Test sieves, sieve shaker, balance. |

| Typical Size Range | Effective for particles larger than approximately 20 micrometers (µm). |

| Main Advantage | Simple, cost-effective, and provides physically separated fractions for further analysis. |

| Main Limitation | Not suitable for very fine powders (<20µm) or materials that clump or have static charge. |

Ready to achieve precise particle sizing and superior quality control in your lab?

Sieve analysis is a cornerstone of material testing, and having the right equipment is crucial for accurate, reproducible results. KINTEK specializes in high-quality lab equipment, including robust test sieves and efficient sieve shakers, designed to meet the rigorous demands of laboratories in construction, manufacturing, pharmaceuticals, and research.

We understand that consistent material properties are non-negotiable for your success. Let us help you build a reliable foundation for your quality control processes.

Contact our experts today to discuss your specific sieve analysis needs and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- Why is sieve analysis important in geotechnical engineering? Unlock Soil Behavior for Safer Construction

- What are the disadvantages of sieve analysis method of particle size analysis? Key Limitations to Consider

- How do you care and maintain a sieve? A Guide to Extending Sieve Life and Accuracy

- What is the importance of particle size analysis by sieving? Ensure Product Quality and Performance

- What are the advantages and disadvantages of sieve analysis test? A Guide to Effective Particle Sizing

- Why must Al2O3/ZrO2 ceramic powders undergo treatment with a standard sieve? Ensuring High-Density Sintering Results

- What are laboratory test sieves used for? A Guide to Particle Size Analysis

- What are the disadvantages of sieving? Key Limitations for Accurate Particle Analysis