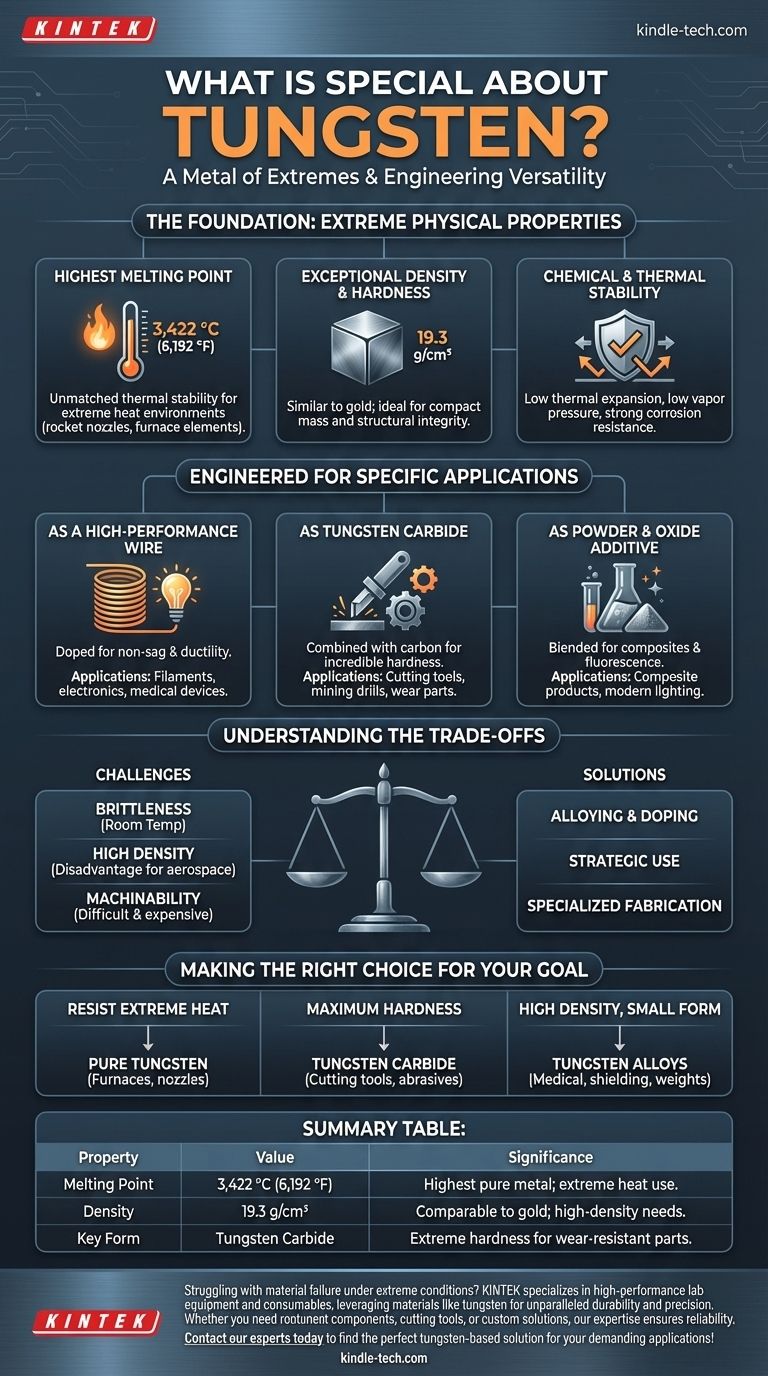

Tungsten is special because it is a metal of extremes. It possesses the highest melting point of any pure metal, exceptional density comparable to gold, and remarkable hardness, making it indispensable for high-performance applications where other materials would fail under intense heat or stress.

The true specialness of tungsten isn't just its list of extreme properties, but its engineering versatility. Its raw characteristics are harnessed in multiple forms—as a pure metal, a durable wire, or a super-hard carbide—to solve very specific and demanding technical challenges that no other element can.

The Foundation: Tungsten's Extreme Physical Properties

Tungsten's value originates from a unique combination of physical traits that set it apart from nearly all other metals. These are the fundamental building blocks for its wide range of applications.

The Highest Melting Point of All Metals

Tungsten has a melting point of 3,422 °C (6,192 °F), the highest of any pure metal.

This exceptional thermal stability allows it to maintain its strength and structure in environments with extreme heat, such as in rocket nozzles or vacuum furnace heating elements.

Exceptional Density and Hardness

With a density of 19.3 g/cm³, tungsten is one of the heaviest elements, nearly identical to gold. This makes it ideal for applications requiring significant mass in a small volume.

It is also a naturally very hard, steel-gray metal with high tensile strength, providing excellent structural integrity.

Chemical and Thermal Stability

Tungsten exhibits a low coefficient of thermal expansion, meaning it doesn't expand or contract much when its temperature changes.

It also has a low vapor pressure at high temperatures and offers strong corrosion resistance, particularly against molten metals and steam.

How Tungsten Is Engineered for Specific Applications

Pure tungsten is rarely the final product. Its true utility is unlocked when it is processed and combined with other elements to enhance specific properties for targeted uses.

As a High-Performance Metal Wire

Tungsten wire is often doped with other elements to improve its properties. This process provides non-sag characteristics and ensures the wire remains ductile at both room and high operating temperatures.

This makes it essential for lighting filaments, electronic device components, medical electrodes, catheter guide wires, and high-temperature thermocouples.

As Tungsten Carbide

When combined with carbon, tungsten forms tungsten carbide, an extremely hard ceramic-like material also known as cemented carbide.

Tungsten carbide is prized for its incredible hardness, toughness, and wear resistance. It is the dominant material used for high-speed cutting tools, mining drills, and other industrial applications requiring superior durability.

As a Powder and Oxide Additive

Tungsten powders can be blended with other materials like iron, platinum, or even polymers to create composite products with unique properties.

Its oxides are also valuable, particularly for their ability to create fluorescence in modern lighting applications.

Understanding the Trade-offs

No material is perfect, and tungsten's extreme properties come with inherent challenges that engineers must manage.

Brittleness at Room Temperature

In its pure form, tungsten can be brittle at room temperature, making it difficult to work with. Doping and alloying are critical processes used to overcome this limitation.

High Density Isn't Always an Advantage

While its weight is an asset for counterweights or radiation shielding, it is a significant drawback in aerospace or automotive applications where lightweight materials are a primary requirement.

Machinability Challenges

The very hardness that makes tungsten so valuable also makes it difficult and expensive to machine and fabricate into complex parts.

Making the Right Choice for Your Goal

Selecting tungsten or one of its derivatives depends entirely on the primary problem you need to solve.

- If your primary focus is resisting extreme heat: Pure tungsten is the ideal choice for components like vacuum furnace heaters, electrical contacts, and rocket engine nozzles.

- If your primary focus is maximum hardness and wear resistance: Tungsten carbide is the definitive solution for cutting tools, abrasives, and mining equipment.

- If your primary focus is high density in a small form factor: Tungsten alloys are excellent for medical device components, counterweights in aerospace, and radiation shielding.

Ultimately, understanding tungsten's distinct forms allows you to select the precise material needed to meet the most demanding engineering requirements.

Summary Table:

| Property | Value | Significance |

|---|---|---|

| Melting Point | 3,422 °C (6,192 °F) | Highest of all pure metals; ideal for extreme heat applications. |

| Density | 19.3 g/cm³ | Comparable to gold; perfect for high-density needs like shielding. |

| Key Form | Tungsten Carbide | Extreme hardness for cutting tools and wear-resistant parts. |

Struggling with material failure under extreme conditions? KINTEK specializes in high-performance lab equipment and consumables, leveraging materials like tungsten for unparalleled durability and precision. Whether you need robust furnace components, cutting tools, or custom material solutions for your laboratory, our expertise ensures reliability and efficiency. Contact our experts today to find the perfect tungsten-based solution for your demanding applications!

Visual Guide

Related Products

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What is the function of high-temperature metal filaments in HFCVD? Catalyzing Diamond Growth Success

- Is tungsten a good heating element? Unlock Extreme Temperatures in Vacuum Environments

- What is the melting point of tungsten? Discover the Metal That Withstands Extreme Heat

- Can tungsten be used as a heating element? Unlocking Extreme Heat for High-Temperature Applications

- What are heating elements with tungsten? Unlock Extreme Heat for Vacuum & Industrial Processes