The primary advantage of the ball milling method lies in its simplicity and low cost, making it a highly accessible technique for reducing particle size. It is a purely mechanical process that uses physical force to alter materials, which can also be leveraged to intentionally introduce structural changes like crystal defects for specific applications.

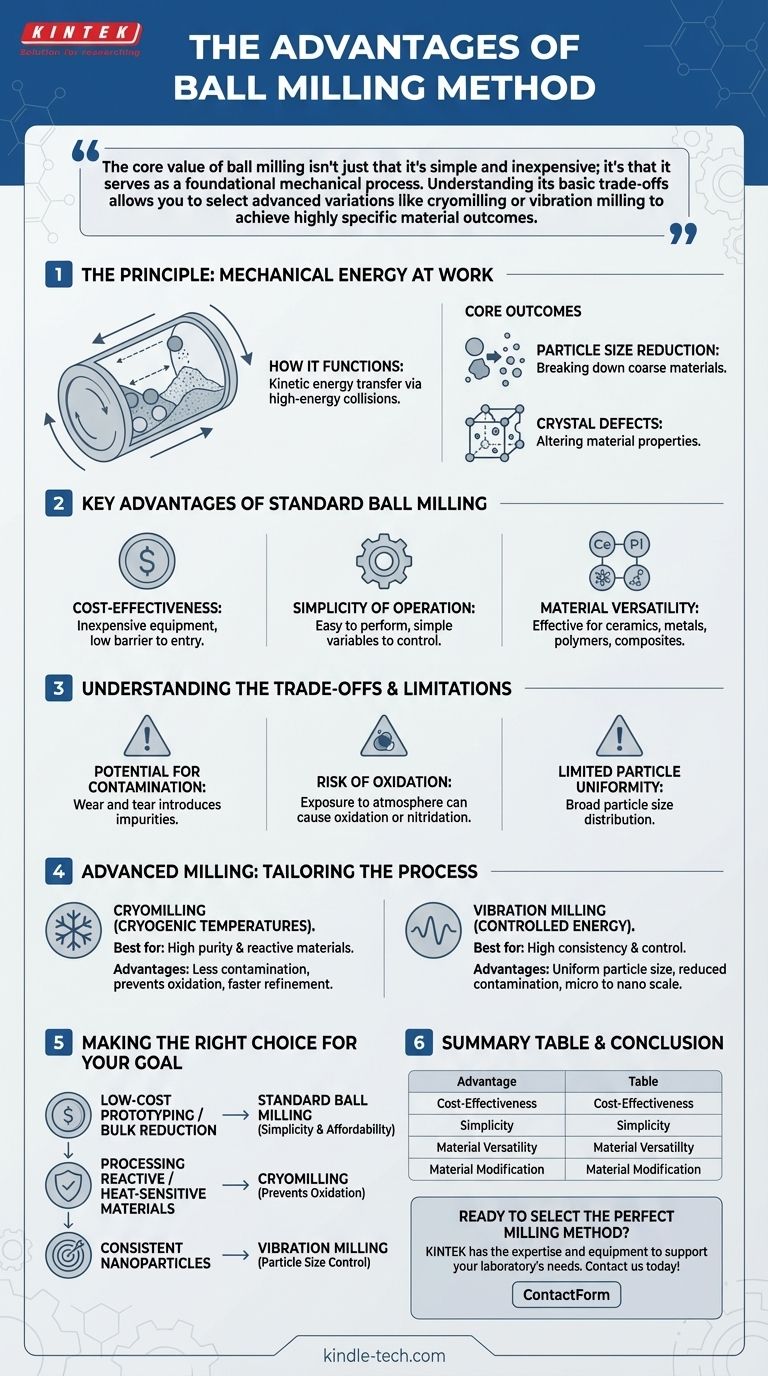

The core value of ball milling isn't just that it's simple and inexpensive; it's that it serves as a foundational mechanical process. Understanding its basic trade-offs allows you to select advanced variations like cryomilling or vibration milling to achieve highly specific material outcomes.

The Principle: Mechanical Energy at Work

How It Functions

Ball milling is a mechanical process where all structural and chemical changes are produced by the direct transfer of kinetic energy. Materials placed in a container with grinding media (balls) are subjected to high-energy collisions as the container rotates.

The Core Outcomes

This repeated impact and shearing force primarily results in particle size reduction, breaking down coarse materials into finer powders. A secondary, and often desirable, outcome is the creation of crystal defects, which can alter the material's electronic or catalytic properties.

Key Advantages of Standard Ball Milling

Cost-Effectiveness

The equipment required for basic ball milling is relatively inexpensive and straightforward compared to more sophisticated material processing technologies. This lowers the barrier to entry for research and small-scale production.

Simplicity of Operation

The method is easy to perform without requiring extensive specialized training. The core variables—milling time, speed, and ball-to-powder ratio—are simple to control and adjust.

Material Versatility

Ball milling can be applied to a vast range of materials. It is effective for grinding hard substances like ceramics and metals as well as softer materials like polymers and composites.

Understanding the Trade-offs and Limitations

Potential for Contamination

A significant drawback of standard ball milling is the risk of contamination. Wear and tear on the milling balls and container walls can introduce impurities into the sample material.

Risk of Oxidation

The process can generate heat and continuously expose fresh, unoxidized surfaces to the atmosphere inside the vial. This can lead to unwanted oxidation or nitridation, especially with reactive materials.

Limited Particle Uniformity

While effective at size reduction, standard ball milling may produce a broad particle size distribution. Achieving a highly uniform, narrow distribution often requires more advanced techniques.

Advanced Milling: Tailoring the Process to Your Needs

For High Purity and Reactive Materials: Cryomilling

Cryomilling is a specialized form of ball milling conducted at cryogenic temperatures (below –150°C). This offers distinct advantages for sensitive applications.

The extreme cold makes materials more brittle, leading to faster refinement and less contamination from the milling tools. It also creates an inert environment that prevents oxidation.

For High Consistency and Control: Vibration Milling

Vibration milling provides more efficient and uniform particle size reduction. By using a closed container and controlled vibrational energy, it ensures a more consistent final product.

This method also significantly reduces contamination from external sources and offers exceptional control, capable of producing particles from the micrometer down to the nanometer scale.

Making the Right Choice for Your Goal

Selecting the appropriate milling technique requires a clear understanding of your material and your desired end-state.

- If your primary focus is low-cost prototyping or bulk size reduction: Standard ball milling offers an unmatched combination of simplicity and affordability.

- If your primary focus is processing reactive metals or heat-sensitive polymers: Cryomilling is the superior choice for preventing oxidation and preserving material integrity.

- If your primary focus is producing highly consistent nanoparticles for advanced applications: Vibration milling provides the necessary control over particle size distribution and purity.

Ultimately, choosing the right milling method is about matching the tool to the specific demands of your project.

Summary Table:

| Advantage | Description |

|---|---|

| Cost-Effectiveness | Inexpensive equipment lowers the barrier for research and small-scale production. |

| Simplicity | Easy to operate with simple variables to control (time, speed, ball-to-powder ratio). |

| Material Versatility | Effective for a wide range of materials, from hard ceramics/metals to softer polymers/composites. |

| Material Modification | Mechanical energy can create crystal defects to alter electronic or catalytic properties. |

Ready to Select the Perfect Milling Method for Your Project?

Whether your goal is simple particle size reduction with standard ball milling, processing reactive materials with cryomilling, or achieving high consistency with vibration milling, KINTEK has the expertise and equipment to support your laboratory's needs.

Contact us today using the form below to discuss your specific material and application requirements. Let our specialists help you achieve superior results with the right lab equipment solution.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the function of a high-energy planetary ball mill in the synthesis of iodo-vanadate-lead ceramic waste forms?

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- What is the role of a planetary ball mill in the synthesis of Li2S–P2S5 sulfide solid-state electrolytes?

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability