In the context of sieve analysis, "amplitude" does not describe a result of the analysis itself, but rather a critical setting on the mechanical sieve shaker used to perform the test. It refers to the intensity of the vibration—how vigorously the stack of sieves is shaken to separate particles by size. This setting is fundamental to achieving an accurate and repeatable particle size distribution.

While sieve analysis appears simple, its accuracy hinges on correctly controlling the physical process. The "amplitude" of the sieve shaker is the most critical variable you control, as it dictates the energy used to separate particles. The core challenge is finding the right balance of vibrational energy for your specific material.

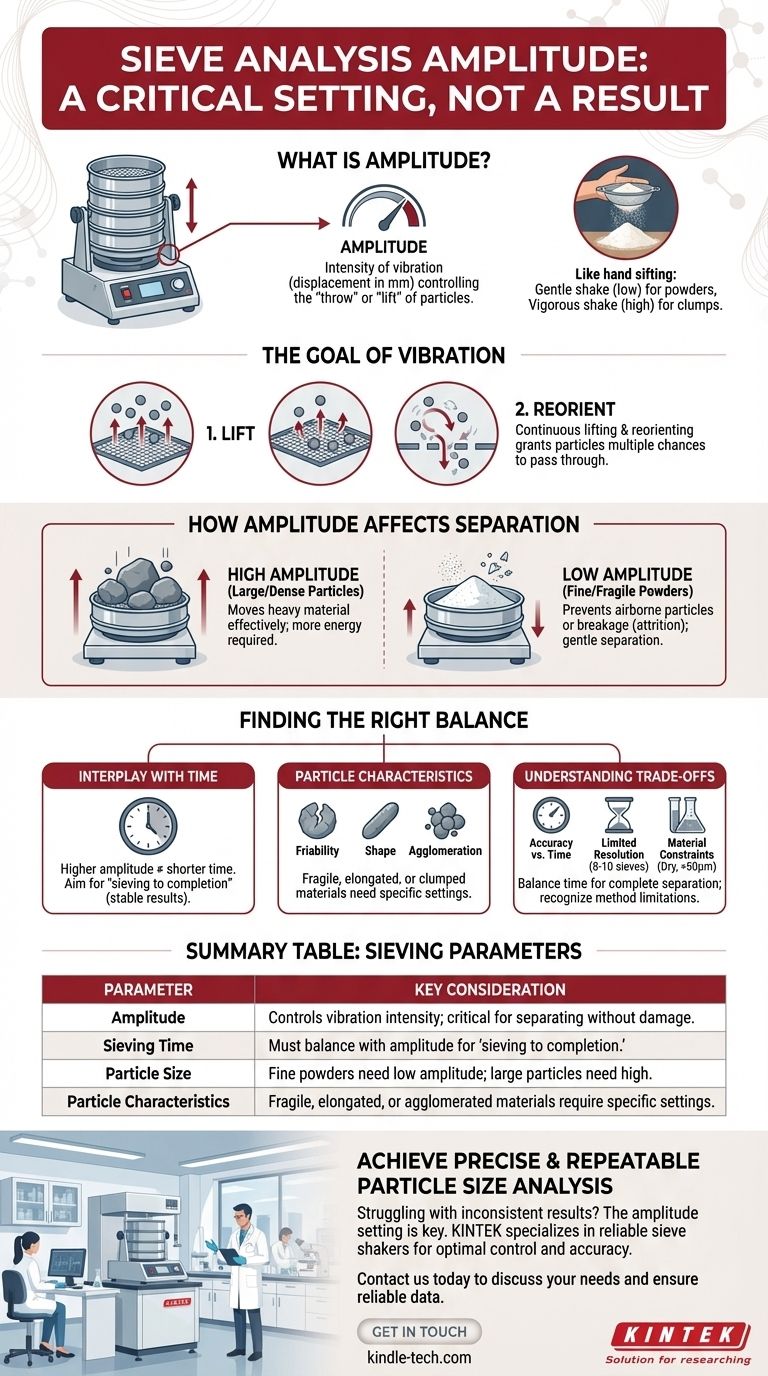

What 'Amplitude' Really Means in Sieving

Sieve analysis relies on mechanical energy to sort particles. Amplitude is the primary lever to control that energy.

Defining Shaker Amplitude

Amplitude is the measure of the sieve's displacement during vibration, typically measured in millimeters. It controls the "throw" or "lift" imparted to the particles on the sieve mesh.

Think of it like sifting flour in a hand sifter. A gentle shake (low amplitude) works for fine powders, while a more vigorous shake (high amplitude) is needed if the flour is clumpy.

The Goal of Proper Vibration

The purpose of the vibration is twofold:

- To lift the bed of particles up off the sieve mesh.

- To allow the individual particles to reorient themselves as they fall back down.

This continuous lifting and reorienting gives each particle multiple opportunities to present itself to a sieve opening and either pass through or be retained.

How Amplitude Affects Particle Separation

The correct amplitude depends entirely on the material being tested.

- For large, dense particles, a higher amplitude is required to impart enough energy to lift and move them effectively across the mesh.

- For fine, low-density powders, a lower amplitude is necessary. Too much energy will cause the fine particles to bounce excessively or even float on a cushion of air, preventing them from ever reaching the sieve mesh to be sorted.

Finding the Right Balance: Key Sieving Parameters

Amplitude does not work in isolation. It is part of a system of variables that must be balanced for an accurate test.

The Interplay of Amplitude and Time

Sieving time is the other major variable. While a higher amplitude can sometimes reduce the required sieving time, there is a point of diminishing returns.

An optimal test is one where the results no longer change with additional time—a state known as "sieving to completion." Simply increasing the amplitude to shorten the time can lead to inaccurate results if particles are not separated properly.

The Influence of Particle Characteristics

The physical nature of your sample is the most important consideration.

- Friability: If your particles are fragile or brittle, a high amplitude can break them. This artificially creates more fine particles and skews your distribution, a phenomenon called attrition.

- Shape: Elongated or flat particles require more opportunities to orient correctly to pass through a square mesh. This may call for a moderate amplitude over a longer sieving time.

- Agglomeration: Some fine powders tend to clump together. A specific amplitude may be needed to break these agglomerates apart without destroying the primary particles.

Understanding the Trade-offs and Limitations

While sieve analysis is valued for its simplicity and low cost, it's essential to recognize its inherent limitations, which are independent of the shaker settings you choose.

Accuracy vs. Time

Achieving truly reproducible results can be time-consuming. You must run tests long enough to ensure that particle separation is complete, which often takes longer than a few minutes. Rushing the process by using excessive amplitude is a common source of error.

Limited Resolution

The output of a sieve analysis is limited by the number of sieves in your stack. A standard stack may have a maximum of 8 sieves, meaning your final particle size distribution curve is based on just 8 data points. This provides a snapshot, not a high-resolution image, of the distribution.

Material Constraints

This technique is most effective for dry, free-flowing particles that are generally larger than 50 micrometers (µm). It is not suitable for cohesive materials, slurries, or very fine powders that tend to agglomerate or float on air currents during shaking.

Setting the Correct Amplitude for Your Goal

Your choice of amplitude should be a deliberate decision based on your material and analytical goals. The process should be validated by ensuring results are repeatable and do not change with additional sieving time.

- If your primary focus is coarse, durable particles (>500 µm): You can likely use a higher amplitude and shorter sieving time to efficiently move the heavy material.

- If your primary focus is fine or fragile powders (<500 µm): Begin with a lower amplitude and a longer sieving time to prevent particle damage and ensure gentle, complete separation.

- If your results are inconsistent: The most likely cause is an incorrect combination of amplitude and time. Systematically test different amplitudes to find the point where results become stable and repeatable.

Mastering the physical settings of your equipment is the foundation of a reliable and accurate particle size analysis.

Summary Table:

| Sieving Parameter | Key Consideration |

|---|---|

| Amplitude | Controls vibration intensity; critical for separating particles without damage. |

| Sieving Time | Must be balanced with amplitude to achieve "sieving to completion." |

| Particle Size | Fine powders need low amplitude; large, dense particles need high amplitude. |

| Particle Characteristics | Fragile, elongated, or agglomerated materials require specific amplitude settings. |

Achieve precise and repeatable particle size analysis with the right equipment.

Struggling with inconsistent sieve analysis results? The amplitude setting on your shaker is often the key. KINTEK specializes in high-quality lab equipment and consumables, including reliable sieve shakers designed for optimal control and accuracy.

Our experts can help you select the right equipment for your specific materials—whether you're working with fine powders or coarse aggregates—ensuring you get reliable data every time.

Contact us today to discuss your laboratory needs and let KINTEK provide the solution for accurate particle sizing. Get in touch via our contact form

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What role does a constant-temperature shaker play in batch adsorption experiments? Key Insights for Lab Efficiency

- What is the function of the sieve shaker machine? Achieve Accurate Particle Size Analysis

- What are the disadvantages of sieve shaker machine? Key Limitations for Accurate Particle Analysis

- Why use reciprocating shakers for AMD & hospital wastewater co-treatment? Optimize nZVI Reaction Kinetics

- What are the primary functions of a laboratory orbital shaker during BMP testing? Maximize Methane Yield Accuracy

- Which technique is best for the determination of particle size? Match Your Material to the Right Method

- What are the two applications of sieving? From Baking to Construction, Master Material Separation

- Why is a multi-stage vibrating sieve system used for sisal residue powders? Maximize Yield and Efficiency