In the context of a sieve shaker, amplitude is not a single, fixed number but rather the intensity or magnitude of the shaking motion. It is a critical, adjustable parameter that, along with frequency, determines how aggressively the shaker separates particles. The correct amplitude is entirely dependent on the physical characteristics of the material being analyzed.

The core principle to understand is that amplitude is a user-controlled setting, not an inherent specification of the machine. The goal is to set an amplitude high enough to fluidize the material and ensure each particle is presented to the sieve openings, but low enough to prevent particle damage and ensure accurate, repeatable results.

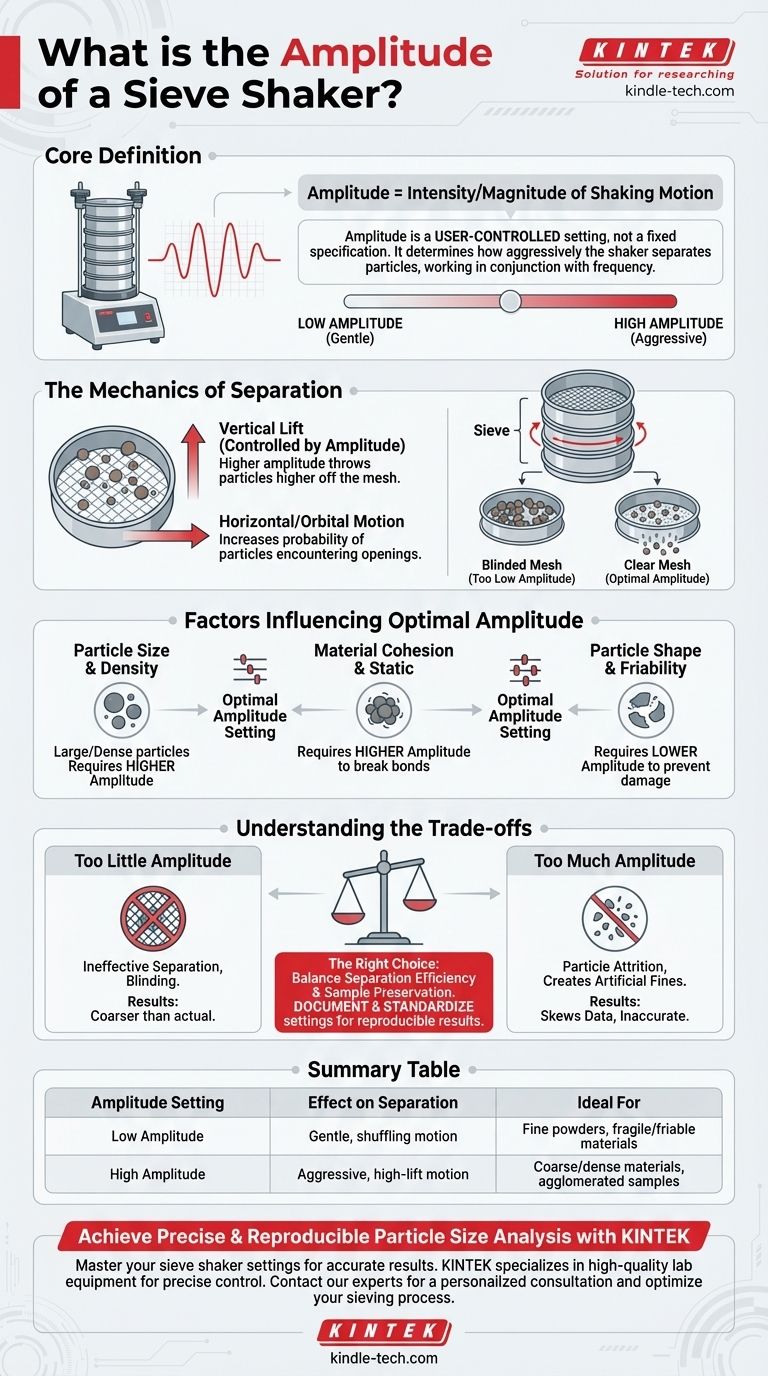

The Role of Amplitude in Particle Separation

To properly use a sieve shaker, one must understand how amplitude directly influences the mechanics of separation. It is the primary force that drives the entire analytical process.

Defining the Shaking Motion

The motion of modern sieve shakers is often a combination of vertical and horizontal movement, sometimes described as orbital motion.

Amplitude controls the vertical lift component of this motion. A higher amplitude throws particles higher off the sieve mesh, while a lower amplitude results in a gentler shuffling action.

The Mechanics of Separation

Effective sieving requires two things: clearing the mesh openings and encouraging particles to pass through them.

Amplitude provides the upward force to lift the entire particle bed, preventing particles from getting stuck in and blocking the mesh openings (blinding). This allows finer particles underneath to reach the screen.

The horizontal or orbital component then moves the particles across the screen, increasing the probability that they will encounter and fall through an opening if they are small enough.

Factors Influencing the Optimal Amplitude

There is no universal "correct" amplitude. The ideal setting is a direct function of the sample material's properties. An adjustment is almost always required when changing from one material type to another.

Particle Size and Density

Larger and denser particles require more energy to be lifted and separated effectively. Therefore, they typically require a higher amplitude setting compared to fine, lightweight powders.

Material Cohesion and Static

Materials that tend to clump together (agglomerate) or hold a static charge require a more aggressive shaking action. A higher amplitude can provide the necessary force to break these bonds and allow individual particles to be analyzed.

Particle Shape and Friability

Fragile or friable materials that can easily break apart require a lower amplitude to prevent particle degradation during analysis. Breaking particles creates fines that weren't in the original sample, leading to inaccurate results. Similarly, irregularly shaped particles may need a specific amplitude to orient them correctly to pass through the mesh.

Understanding the Trade-offs

Setting the amplitude is a balancing act. Choosing an incorrect setting is one of the most common sources of error in sieve analysis.

The Risk of Too Little Amplitude

If the amplitude is set too low, the particles will not lift sufficiently from the sieve mesh. This leads to ineffective separation and causes the mesh to become blinded, yielding inaccurate results that show the material as being coarser than it actually is.

The Risk of Too Much Amplitude

If the amplitude is set too high, particles may be thrown so high that they don't have enough time to interact with the mesh and pass through the openings. More importantly, this aggressive action can cause particle attrition, damaging the particles and creating artificial fine material, which skews the results.

The Impact on Reproducibility

For particle size analysis to be a reliable quality control tool, it must be repeatable. Using a different amplitude for the same material will produce different results. Documenting and standardizing the amplitude setting for each specific test is critical for achieving accurate and reproducible data over time.

Making the Right Choice for Your Goal

Your ideal setting is a balance between separation efficiency and sample preservation. The best practice is often to start low and observe the material's behavior, increasing the amplitude until the entire sample is mobile and separation occurs smoothly.

- If your primary focus is coarse, dense, or agglomerated materials: You will likely need a higher amplitude to provide the energy required to fluidize the sample bed and break up clumps.

- If your primary focus is fine powders or fragile crystals: Begin with a low amplitude and increase it only as needed to prevent particle damage and ensure an accurate measurement of the original sample.

- If your primary focus is achieving highly reproducible results: You must standardize and document the exact amplitude setting, sieving time, and sample weight for each specific material test protocol.

Ultimately, mastering the amplitude setting transforms a sieve shaker from a simple machine into a precision analytical instrument.

Summary Table:

| Amplitude Setting | Effect on Separation | Ideal For |

|---|---|---|

| Low Amplitude | Gentle, shuffling motion | Fine powders, fragile/friable materials |

| High Amplitude | Aggressive, high-lift motion | Coarse/dense materials, agglomerated samples |

Achieve precise and reproducible particle size analysis with the right equipment from KINTEK.

Mastering your sieve shaker's settings is key to accurate results. KINTEK specializes in high-quality lab equipment, including sieve shakers designed for precise control over amplitude and other critical parameters. Our experts can help you select the ideal shaker for your specific materials—whether you're working with fragile ceramics or dense aggregates—ensuring your lab operates with maximum efficiency and data integrity.

Ready to optimize your sieving process? Contact our team today for a personalized consultation and discover how KINTEK can support your laboratory's needs.

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What are the primary functions of automated crushing and sieving systems in e-waste recycling? Optimize Material Recovery

- Why is a constant temperature shaker required during the impregnation of manganese salts onto activated carbon?

- How does the fractional sieving step contribute to the efficiency of the microwave-assisted pyrolysis process? Cost Reduction

- What is the principle of vibrating sieve? Achieve Precise Particle Separation with Mechanical Vibration

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- What is the speed of a sieve shaker? Discover the Key to Accurate Particle Sizing

- What is the function of a benchtop shaker in zirconium extraction? Achieve Rapid Chemical Equilibrium Efficiency

- What role does a constant-temperature shaker play in batch adsorption experiments? Key Insights for Lab Efficiency