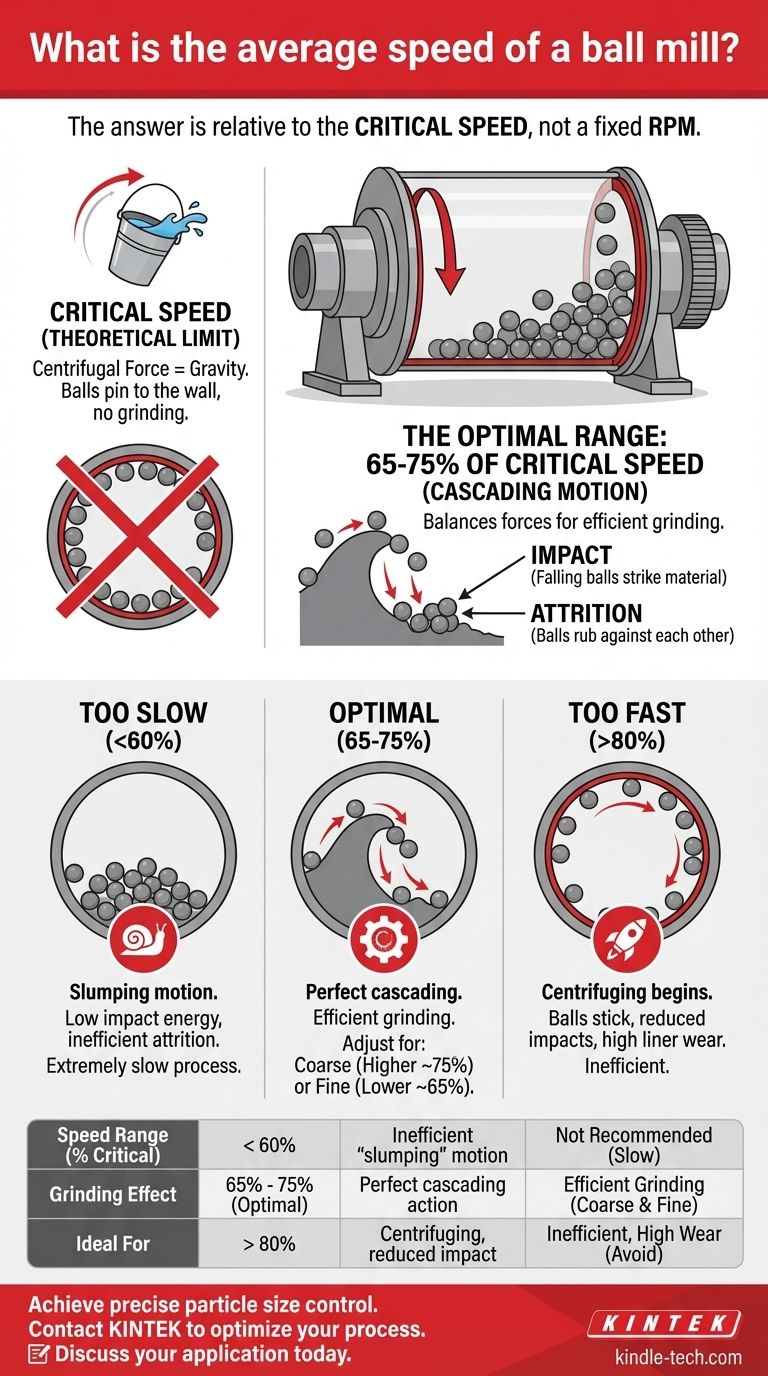

In practice, there is no single "average speed" for a ball mill. Instead, the correct speed is always determined relative to its unique critical speed. The optimal operating speed for effective grinding is consistently found within a specific percentage range of this critical speed, typically between 65% and 75%.

The central principle of ball mill operation is not to achieve a specific RPM, but to establish a precise "cascading" motion of the grinding media. This is accomplished by operating at a calculated percentage of the mill's critical speed, balancing the forces of gravity and rotation to maximize grinding efficiency.

The Concept of Critical Speed

To understand the correct operating speed, you must first grasp the concept of critical speed. This isn't the goal; it's the absolute upper limit you must avoid.

What is Critical Speed?

Critical speed is the theoretical rotational speed at which the centrifugal force inside the mill precisely matches the force of gravity.

At this speed, the grinding media (the balls) are pinned against the inner wall of the drum for the entire revolution. They are carried up, over the top, and back down without ever falling.

Think of swinging a bucket of water over your head. If you swing it fast enough (at its critical speed), the water stays in the bucket. The same principle applies to the balls in the mill.

Why Operating AT Critical Speed Fails

When the balls are pinned to the side of the mill, they no longer tumble or fall. There is no impact and no grinding action.

The material and the media simply rotate together as one solid mass. This results in zero grinding and can cause excessive wear on the mill's lining.

Finding the "Sweet Spot": Optimal Operating Speed

The goal is to use rotation to lift the balls and then let gravity take over to create the grinding action. This balance occurs well below the critical speed.

The Importance of Cascading Motion

The most efficient grinding occurs when the balls are carried roughly two-thirds of the way up the mill wall and then tumble back down in a continuous, cascading wave.

This motion creates two primary grinding forces:

- Impact: Balls falling and striking the material below.

- Attrition: Balls rubbing against each other and the material as they tumble.

The speed of the mill directly controls the nature of this cascade.

The Industry Standard Range

The optimal operating speed is almost universally accepted to be 65% to 75% of the calculated critical speed.

- Slower Speeds (~65%): Promotes more attrition and less impact, ideal for achieving a very fine final product.

- Faster Speeds (~75%): Promotes more impact and less attrition, ideal for breaking down coarser materials quickly.

Understanding the Trade-offs of Speed

Choosing a speed outside the optimal range leads to rapidly diminishing returns and process inefficiency.

Operating Too Slowly (<60% Critical Speed)

If the mill rotates too slowly, the balls are not lifted high enough. They simply slide or "slump" back down near the bottom of the mill.

This results in very little impact energy. Grinding relies almost entirely on weak attrition, making the process extremely slow and inefficient.

Operating Too Quickly (>80% Critical Speed)

As you approach and exceed 80% of critical speed, centrifuging begins. The balls are thrown further and begin to stick to the mill wall.

This dramatically reduces the cascading action and the number of impacts, crippling the grinding efficiency. It also concentrates wear on the mill liner.

Setting the Right Speed for Your Goal

The ideal speed is not a fixed number but a strategic choice based on your desired outcome. To determine your target speed, you must first calculate the theoretical critical speed for your specific mill and then apply the appropriate percentage.

- If your primary focus is coarse grinding (impact): Operate toward the higher end of the range, around 75% of critical speed.

- If your primary focus is fine grinding (attrition): Operate toward the lower end of the range, around 65% of critical speed.

- If you are unsure or need a balanced profile: Begin at 70% of critical speed and adjust based on the output.

Controlling the speed relative to this critical threshold is the most direct way you can control the efficiency and outcome of your milling process.

Summary Table:

| Speed Range (% of Critical Speed) | Grinding Effect | Ideal For |

|---|---|---|

| < 60% | Inefficient 'slumping' motion | Not Recommended |

| 65% - 75% (Optimal) | Perfect cascading action | Efficient grinding |

| > 80% | Centrifuging, reduced impact | Inefficient, high wear |

Achieve precise particle size control and maximize your grinding efficiency. The correct ball mill speed is critical for your results. KINTEK specializes in high-performance lab ball mills and consumables, providing the reliable equipment you need for consistent, efficient milling.

Let our experts help you optimize your process. Contact KINTEK today to discuss your specific application and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Single Horizontal Jar Mill

People Also Ask

- How does ball milling equipment influence powder metallurgy? Master Superalloy Preparation & Precision Modeling

- What is the primary function of a mechanical ball mill in NZSP synthesis? Optimize Precursor Homogeneity

- What is the difference between a ball mill and a bead mill? Choose the Right Mill for Your Particle Size Goal

- What are the advantages of using wet ball milling with anhydrous ethanol? Achieve Superior Ag-SnO2-Y2O3 Powder Quality

- What is grinding media made of? Select the Right Material for Your Milling Process

- What is the diameter of the balls in a ball mill? Optimize Your Grinding Efficiency with the Right Size

- Why is a laboratory ball mill required for the homogenization of leaching residues? Ensure Precise Analytical Results

- How does mechanical ball milling compare to sol-gel for oxide coating? Streamline Your Lab Equipment Workflow