Choosing the right material for a pyrolysis reactor is a critical decision that directly impacts safety, longevity, and operational efficiency. The most common and reliable materials are specialized boiler plates, such as Q245R and Q345R, and specific grades of stainless steel, including 304 and 306. The best choice depends entirely on your specific operational needs.

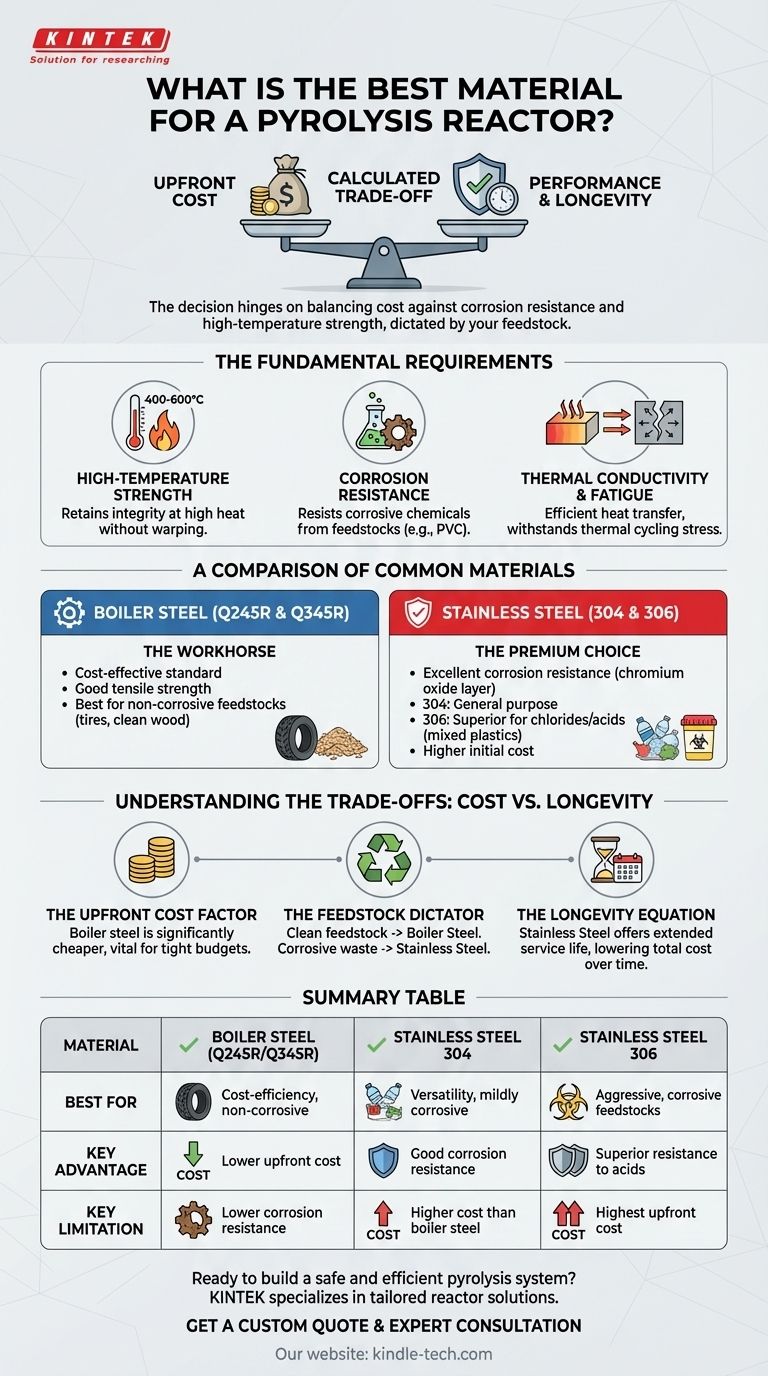

The "best" material is not a single answer but a calculated trade-off. The decision hinges on balancing the upfront cost of boiler steel against the superior corrosion resistance and high-temperature strength of stainless steel, a choice dictated primarily by your feedstock and budget.

The Fundamental Requirements of a Reactor Material

A pyrolysis reactor operates under extreme conditions. The material selected must be ableto withstand a challenging environment of high heat, corrosive chemicals, and mechanical stress.

High-Temperature Strength

Pyrolysis requires maintaining high temperatures (typically 400-600°C or higher) in an oxygen-free environment. The reactor material must retain its structural integrity at these temperatures without warping, creeping, or failing under pressure.

Corrosion Resistance

Many feedstocks, particularly mixed plastics like PVC or certain types of biomass, release corrosive compounds like hydrochloric acid or sulfuric compounds when heated. The reactor material must resist this chemical attack to prevent rapid degradation and ensure a long service life.

Thermal Conductivity and Fatigue

The reactor must efficiently transfer heat from the external source to the internal feedstock. It must also withstand the stress of thermal cycling—the repeated process of heating up for a batch and cooling down afterward—which can cause material fatigue and cracking over time.

A Comparison of Common Materials

The choice between boiler steel and stainless steel represents a classic engineering trade-off between cost and performance.

Boiler Steel (Q245R & Q345R): The Workhorse

These materials are carbon-manganese steels specifically designed for manufacturing pressure vessels. They are the standard for many pyrolysis applications due to their cost-effectiveness.

Q245R and Q345R offer good tensile strength and durability at the typical operating temperatures of pyrolysis. They are an excellent, economical choice for processing relatively clean and non-corrosive feedstocks like scrap tires or untreated wood.

Stainless Steel (304 & 306): The Premium Choice

Stainless steels are alloys containing chromium, which forms a passive, self-repairing oxide layer that provides excellent corrosion resistance.

Grade 304 is a general-purpose stainless steel that offers a significant upgrade in corrosion resistance over boiler plate. It is well-suited for systems that may process a variety of feedstocks with mild corrosive potential.

Grade 306 contains molybdenum, which dramatically increases its resistance to chlorides and other acidic compounds. This makes it the superior choice for processing aggressive feedstocks like mixed plastic waste, which may contain PVC.

Understanding the Trade-offs: Cost vs. Longevity

Your decision should not be based on material properties alone, but on how those properties align with your business goals.

The Upfront Cost Factor

There is no ambiguity here: boiler steel like Q245R is significantly less expensive than stainless steel. For new ventures or operations with tight capital constraints, boiler steel is often the only viable starting point.

The Feedstock Dictator

The chemical composition of your input material is the most critical variable. If you are processing a consistent stream of clean tires, the added expense of stainless steel is likely unnecessary.

However, if you plan to process mixed municipal or medical waste, the corrosive elements present will rapidly degrade a standard boiler steel reactor, leading to costly downtime and premature replacement.

The Longevity Equation

While a stainless steel reactor has a much higher initial cost, its extended service life in a corrosive environment can lead to a lower total cost of ownership over time. A reactor that lasts 10 years instead of 3 provides far greater value and operational stability.

Making the Right Choice for Your Feedstock

Ultimately, your intended use case determines the optimal material. Assess your goals and choose the material that provides the necessary performance without over-engineering the solution.

- If your primary focus is cost-efficiency with non-corrosive feedstock (e.g., tires, clean biomass): Boiler steel like Q245R or Q345R offers the best balance of performance and affordability.

- If your primary focus is longevity and processing corrosive feedstock (e.g., mixed plastics, medical waste): Stainless steel, particularly Grade 306, is a necessary investment to prevent rapid reactor degradation.

- If you are building a versatile, multi-feedstock system for long-term operation: Investing in stainless steel provides the operational flexibility and durability to handle a wider range of materials safely and effectively.

By aligning your material choice with your specific feedstock and operational goals, you ensure a safe, reliable, and profitable pyrolysis operation.

Summary Table:

| Material | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Boiler Steel (Q245R/Q345R) | Cost-efficiency; non-corrosive feedstocks (tires, clean biomass) | Lower upfront cost | Lower corrosion resistance |

| Stainless Steel 304 | Versatility; mildly corrosive feedstocks | Good corrosion resistance | Higher cost than boiler steel |

| Stainless Steel 306 | Aggressive, corrosive feedstocks (mixed plastics, medical waste) | Superior resistance to chlorides/acids | Highest upfront cost |

Ready to build a safe and efficient pyrolysis system?

The right reactor material is the foundation of your operation's success. KINTEK specializes in providing high-quality lab equipment and consumables, including reactor solutions tailored to your specific feedstock and operational goals. Our experts can help you navigate the trade-offs between boiler steel and stainless steel to maximize your ROI and ensure long-term reliability.

Contact us today to discuss your project requirements and let us help you select the perfect reactor material for your needs.

Get a Custom Quote & Expert Consultation

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS