In essence, the Chemical Vapor Deposition (CVD) process for silicon carbide is a highly controlled manufacturing method used to grow an exceptionally pure and uniform solid material from a gas. Volatile precursor gases containing silicon and carbon are introduced into a high-temperature reaction chamber, where they decompose on a heated surface (the substrate) to form a dense, high-performance silicon carbide coating or solid part, layer by layer.

The core principle of CVD is not just about creating silicon carbide, but about achieving a level of material purity and structural perfection that is unattainable with most conventional methods. This precision is what makes it indispensable for mission-critical, high-technology applications.

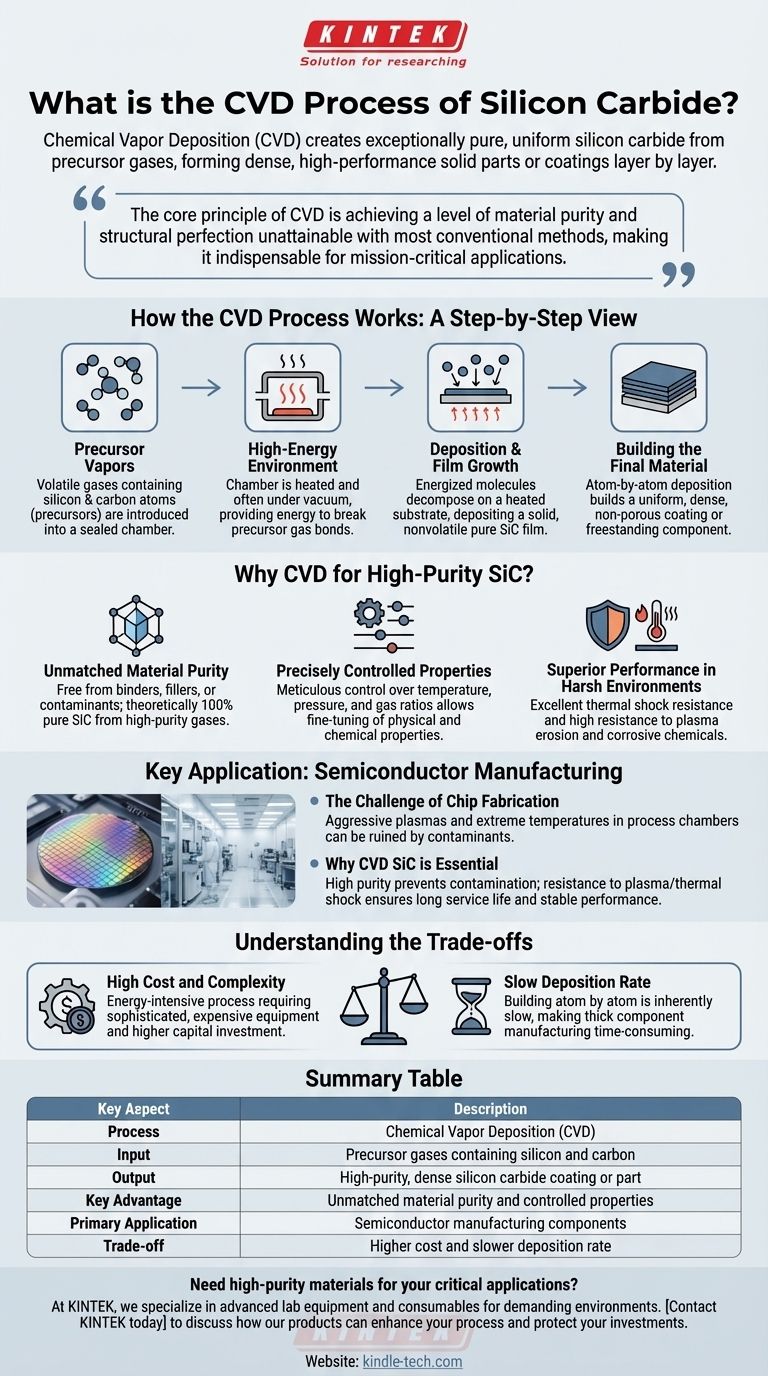

How the CVD Process Works: A Step-by-Step View

The CVD process transforms simple gases into a highly advanced solid material through a carefully orchestrated series of physical and chemical events.

The Precursor Vapors

The process begins by introducing specific volatile gases, known as precursors, into a sealed reaction chamber. These gases are selected because they contain the necessary silicon and carbon atoms and will react predictably at high temperatures.

The High-Energy Environment

The chamber is heated to a precise reaction temperature, often while under a vacuum. This combination of heat and low pressure provides the necessary energy to break the chemical bonds within the precursor gas molecules.

Deposition and Film Growth

Inside the chamber, a substrate material is heated. When the energized gas molecules come into contact with this hot surface, they undergo a chemical reaction or decomposition. This reaction deposits a solid, nonvolatile film of pure silicon carbide (SiC) directly onto the substrate.

Building the Final Material

This deposition occurs atom by atom, building up a thin film that is perfectly uniform and covers all exposed areas of the substrate. Over time, these layers accumulate to create a coating or even a freestanding solid component with a dense, non-porous structure.

Why CVD is the Method of Choice for High-Purity SiC

While other methods can produce silicon carbide, CVD is chosen when performance and purity are the most critical factors. Its advantages stem directly from the nature of the process.

Unmatched Material Purity

Because the material is built directly from filtered, high-purity gases, the final silicon carbide product is free from the binders, fillers, or contaminants often present in traditional ceramic processes. This results in a material that is theoretically 100% pure SiC.

Precisely Controlled Properties

Engineers have meticulous control over the final material. By adjusting parameters like temperature, pressure, and the ratio of precursor gases, they can fine-tune the physical and chemical properties of the silicon carbide to meet exact specifications.

Superior Performance in Harsh Environments

The resulting material exhibits exceptional characteristics. It has excellent thermal shock resistance, meaning it can withstand rapid temperature changes without cracking. It is also highly resistant to erosion from the high-energy plasmas and corrosive chemicals used in advanced manufacturing.

Key Application: Semiconductor Manufacturing

The unique properties of CVD silicon carbide make it a critical material in the semiconductor industry, where environments are extremely demanding.

The Challenge of Chip Fabrication

Semiconductor process chambers, particularly those for oxide etching and rapid thermal processing (RTP), involve aggressive plasmas and extreme temperature cycles. Any contamination from equipment components can ruin an entire wafer of microchips, costing millions.

Why CVD SiC is Essential

CVD SiC is the ideal material for components inside these chambers. Its high purity ensures it does not introduce contaminants into the process. Its resistance to plasma erosion and thermal shock guarantees a long service life and stable performance, protecting the delicate silicon wafers.

Understanding the Trade-offs

Despite its clear advantages, the CVD process is not a universal solution. A trusted advisor must acknowledge its inherent trade-offs.

High Cost and Complexity

CVD is a complex, energy-intensive process requiring sophisticated and expensive equipment. The capital investment and operational costs are significantly higher than for methods like sintering or reaction bonding.

Slow Deposition Rate

Building a material atom by atom is inherently slow. Manufacturing thick, bulk components via CVD can take a very long time, which further contributes to the cost and limits its use for applications where speed and volume are the primary drivers.

Making the Right Choice for Your Application

Selecting the correct material and process requires a clear understanding of your project's primary goal.

- If your primary focus is extreme purity and performance: Specify CVD SiC for applications where material failure or contamination is not an option, such as in semiconductor process equipment.

- If your primary focus is resistance to harsh environments: Choose CVD SiC for components that will be exposed to aggressive chemicals, high-energy plasmas, or rapid and extreme temperature changes.

- If your primary focus is cost-sensitivity on a bulk component: You must evaluate if the superior properties of CVD justify its higher cost compared to other manufacturing methods for silicon carbide.

Ultimately, understanding the CVD process is key to leveraging silicon carbide's full potential in the world's most demanding technological applications.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Chemical Vapor Deposition (CVD) |

| Input | Precursor gases containing silicon and carbon |

| Output | High-purity, dense silicon carbide coating or part |

| Key Advantage | Unmatched material purity and controlled properties |

| Primary Application | Semiconductor manufacturing components |

| Trade-off | Higher cost and slower deposition rate |

Need high-purity materials for your critical applications?

The CVD process is essential for creating silicon carbide that performs reliably in the most demanding environments, like semiconductor fabrication. At KINTEK, we specialize in providing advanced lab equipment and consumables that meet these stringent requirements.

Let us help you achieve superior results. Our expertise ensures you get the right solutions for your laboratory's specific challenges in material science and high-tech manufacturing.

Contact KINTEK today to discuss how our products can enhance your process and protect your investments.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition