In simple terms, a sieve shaker is a laboratory instrument that automates the process of sorting particles by size. It works by vigorously shaking a stack of nested sieves, each with a different mesh size, allowing material to pass through progressively finer screens to determine its particle size distribution.

The core function of a sieve shaker is to replace inconsistent manual hand sieving with a mechanical process, delivering significantly more accurate, efficient, and repeatable results for particle analysis.

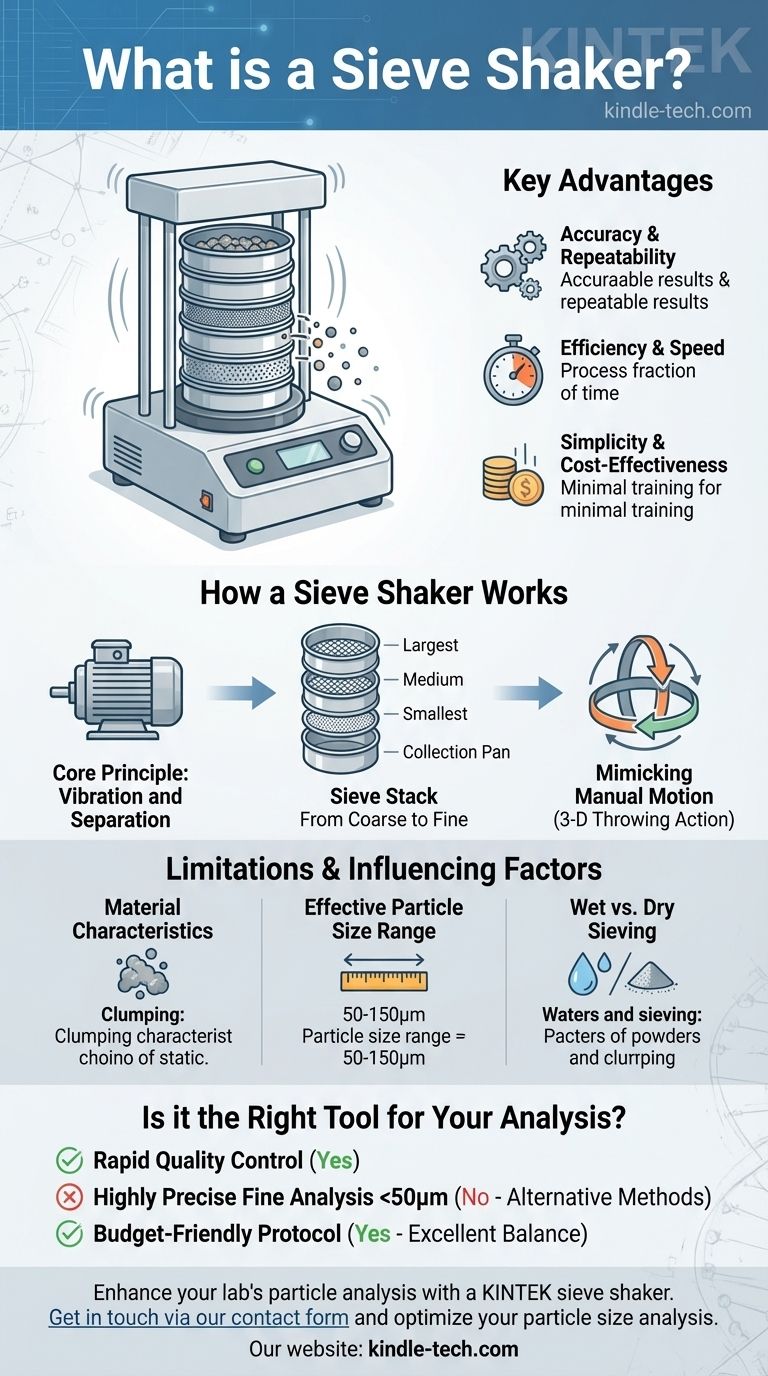

How a Sieve Shaker Works

A sieve shaker’s design is straightforward but highly effective. It combines a powerful motion with a precisely organized set of tools to achieve particle separation.

The Core Principle: Vibration and Separation

At the heart of the machine is a vibration source, typically an electric motor. This motor drives the base of the shaker, creating a consistent and powerful vibrating or oscillating motion.

This motion is transferred directly to a stack of test sieves mounted on the base, causing the material within them to agitate.

The Sieve Stack: From Coarse to Fine

The sieves are stacked in a specific order: the sieve with the largest mesh opening is placed on top, followed by sieves of progressively smaller openings, with a solid collection pan at the very bottom.

As the stack shakes, particles smaller than the mesh openings of a given sieve fall through to the one below it. This process continues until the particles are retained on a sieve they are too large to pass through.

Mimicking Manual Motion

The motion generated by a modern sieve shaker is engineered to replicate the ideal actions of hand sieving. Early methods were described as rotating a sieve while tapping it on the side.

Modern shakers use advanced motions, sometimes described as a 3-D throwing action, to ensure particles are constantly reoriented and have the maximum opportunity to pass through the mesh openings.

Key Advantages of Using a Sieve Shaker

Automating the sieving process provides several critical benefits over manual methods, making it a standard for quality control and material analysis in many industries.

Accuracy and Repeatability

The primary advantage is reproducible results. The machine provides the same motion for the same duration every time, eliminating the human variability inherent in hand sieving.

Efficiency and Speed

A sieve shaker can process a sample in a fraction of the time it would take to do so manually. It allows for multilevel testing, separating a sample into multiple size fractions simultaneously.

Simplicity and Cost-Effectiveness

Operating a sieve shaker requires minimal training. Compared to more complex particle analysis methods like laser diffraction, sieving is a highly cost-effective and accessible technique.

Understanding the Limitations and Influencing Factors

While powerful, the effectiveness of a sieve shaker is not absolute. The characteristics of the material being tested play a significant role in the accuracy of the results.

Material Characteristics Matter

The nature of the sample is crucial. Materials that tend to clump together (agglomeration) or hold a static electric charge can be difficult to sieve accurately, as particles may not separate and pass freely through the mesh.

Effective Particle Size Range

Sieve shakers are excellent for analyzing coarse materials down to finer powders, typically around 50 to 150 micrometers (µm). For particles smaller than this, the method becomes less reliable, and alternative analysis techniques may be required.

Wet vs. Dry Sieving

While most commonly used for dry powders, many shakers can be adapted for wet sieve analysis. This is useful for materials that agglomerate when dry, but it's only viable if the material is not adversely affected by the liquid used for dispersion.

Is a Sieve Shaker the Right Tool for Your Analysis?

Choosing the right instrument depends entirely on your material and your analytical goals.

- If your primary focus is rapid quality control for granular or powdered materials: A sieve shaker is an ideal choice due to its speed, simplicity, and repeatable results.

- If your primary focus is highly precise analysis of very fine particles (sub-50µm): You should investigate alternative methods, as you are approaching the lower limit of sieving technology.

- If your primary focus is establishing a budget-friendly, reliable testing protocol: A sieve shaker provides an excellent balance of low initial cost and accurate, industry-accepted data.

Ultimately, a sieve shaker provides a robust and dependable foundation for understanding and controlling the physical character of particulate materials.

Summary Table:

| Aspect | Description |

|---|---|

| Core Function | Automates particle separation by size using vibrating sieves. |

| Key Advantages | Accuracy, repeatability, efficiency, and cost-effectiveness. |

| Typical Particle Range | 50 to 150 micrometers (µm). |

| Ideal For | Rapid quality control of granular and powdered materials. |

Ready to enhance your lab's particle analysis?

A KINTEK sieve shaker delivers the accuracy and efficiency your quality control process demands. Our reliable instruments are designed to provide the repeatable results you need for consistent material testing.

Contact us today to find the perfect sieving solution for your laboratory. Get in touch via our contact form and let our experts help you optimize your particle size analysis.

Visual Guide

Related Products

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Oscillating Orbital Shaker

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- Why are crushing and sieving systems necessary for biomass pyrolysis? Ensure Feedstock Quality and High Yields

- How do you use a sieve shaker? Master Particle Size Analysis for Quality Control

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- How does a precision sieving system contribute to waste eggshell powder in construction? Improve Strength & Stability

- What is the procedure of sieve shaker? A Step-by-Step Guide to Accurate Particle Size Analysis

- What are the primary functions of automated crushing and sieving systems in e-waste recycling? Optimize Material Recovery

- Why is the use of high-precision analytical sieve shakers necessary for LPBF? Ensure Perfect Metal Powder Consistency

- What key role does sieving equipment play in all-solid-state battery powder processing? Ensure SPS Structural Integrity