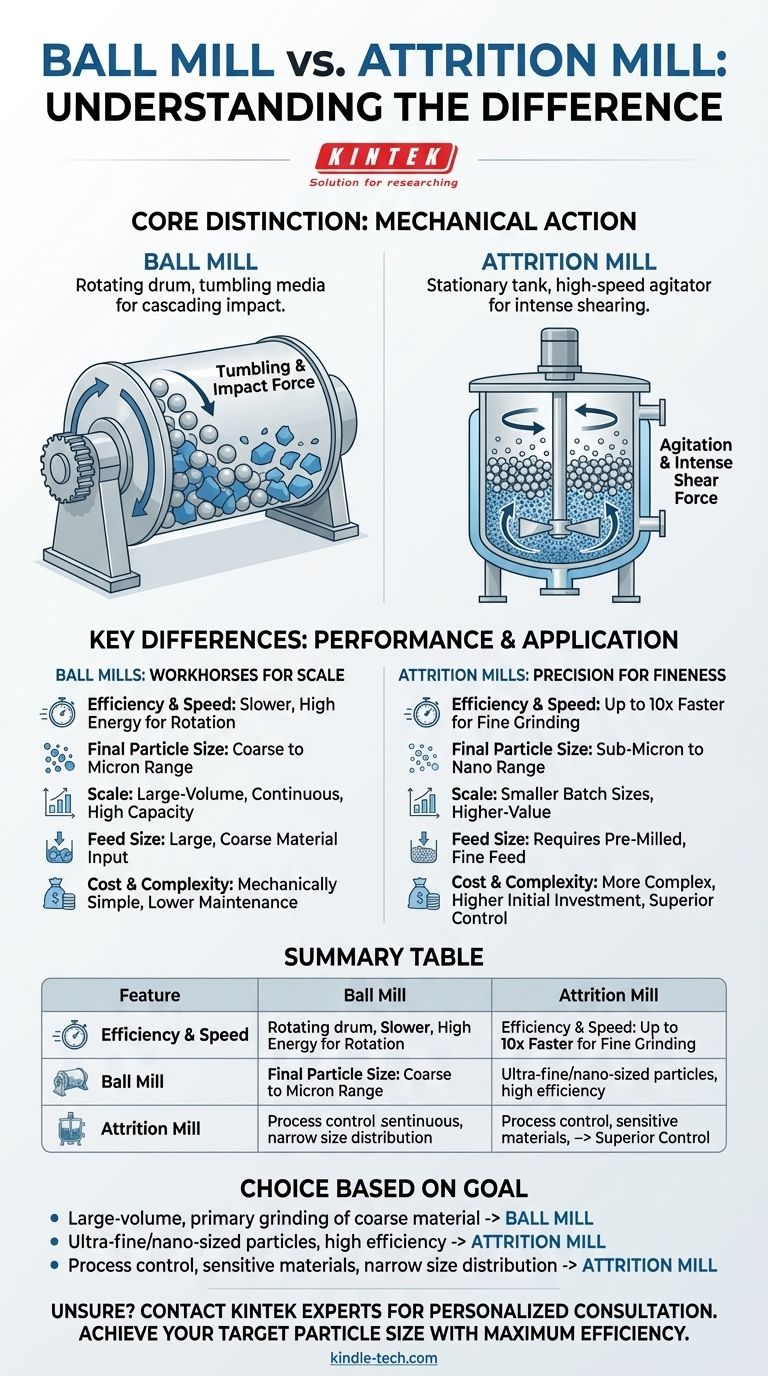

At their core, the fundamental difference between a ball mill and an attrition mill lies in their mechanical action. A ball mill is a rotating drum that tumbles grinding media to create a cascading impact, while an attrition mill is a stationary tank that uses a high-speed internal agitator to create intense shearing forces within the media.

The choice between them is a choice between scale and fineness. Ball mills are workhorses for coarse, large-volume grinding, whereas attrition mills are precision instruments for creating ultra-fine particles with superior speed and efficiency.

Understanding the Mechanical Action

To select the right tool, you must first understand how each one works. The physical design of the mill directly dictates the type of grinding force it applies to the material.

The Ball Mill: Tumbling and Impact

A ball mill is a hollow cylindrical shell that rotates on its axis. It is partially filled with the material to be ground, plus a grinding medium—typically steel or ceramic balls.

As the drum rotates, it carries the media up the side until gravity overcomes the centrifugal force, causing the media to cascade down onto the material below. This action produces size reduction primarily through impact and secondarily through attrition (rubbing).

Different designs exist, such as planetary ball mills and horizontal rolling mills, but the principle of tumbling media remains the same. The mill's diameter dictates grinding performance, while its length primarily affects capacity.

The Attrition Mill: Agitation and Shear

An attrition mill, often called an attritor, consists of a stationary, jacketed tank. Inside, a central shaft with arms (an agitator) rotates at high speed through a bed of very small grinding media.

This high-speed agitation creates intense and continuous motion. The grinding occurs not from tumbling, but from the powerful shearing and rubbing forces generated as the countless media particles rub against each other and the material. This process is significantly more energetic and efficient than the action in a ball mill.

Key Differences in Performance and Application

The contrast in mechanical action leads to significant differences in results, making each mill suitable for very different goals.

Grinding Efficiency and Speed

Because all the energy in an attrition mill is transferred directly to agitating the media, it is far more energy-efficient and faster than a ball mill, which must expend considerable energy simply to rotate a heavy drum. For fine grinding, an attritor can be up to ten times faster than a conventional ball mill.

Final Particle Size

Ball mills are excellent for reducing materials from pebble size down to the micron range. They are the standard for many industrial primary grinding tasks.

Attrition mills, however, excel at producing sub-micron or nano-sized particles. The intense shear is uniquely effective at breaking down materials to a much finer state than is practical with a ball mill.

Process Control

Attrition mills often offer superior process control. The stationary, jacketed tank allows for precise temperature management, which is critical for heat-sensitive materials. The process is continuous and samples can be taken easily without stopping the operation.

Understanding the Trade-offs

Neither technology is universally superior. The optimal choice depends entirely on balancing your project's specific needs for scale, cost, and final particle characteristics.

Scale and Capacity

Ball mills can be scaled to massive industrial sizes, capable of processing hundreds of tons per hour. They are built for high-volume, continuous production.

Attrition mills are typically used for smaller batch sizes, ranging from laboratory scale to a few hundred gallons. They are better suited for higher-value materials where fine particle size and quality control are paramount.

Feed Material Size

A key advantage of the ball mill is its ability to accept a much larger feed size. It can break down coarse materials directly.

An attrition mill requires a much finer starting material, often needing a pre-milling step before the material can be processed effectively.

Cost and Complexity

Ball mills are mechanically simple and robust, often resulting in lower initial and maintenance costs for their size.

Attrition mills are more complex machines with high-speed agitators and seals. While their operational efficiency can lead to long-term savings, the initial capital investment is typically higher.

Making the Right Choice for Your Goal

Your final decision should be guided by your end objective.

- If your primary focus is large-volume, primary grinding of coarse material: A ball mill is the clear choice for its high capacity, simplicity, and ability to handle large feed sizes.

- If your primary focus is producing ultra-fine or nano-sized particles with high efficiency: An attrition mill is the superior technology due to its speed and intense shearing action.

- If your primary focus is process control and working with sensitive materials: An attrition mill provides better capabilities for managing temperature and achieving a narrow particle size distribution.

Understanding this fundamental distinction between tumbling impact and agitated shear empowers you to select the precise tool for your material processing needs.

Summary Table:

| Feature | Ball Mill | Attrition Mill |

|---|---|---|

| Mechanical Action | Tumbling & Impact | Agitation & Shear |

| Primary Force | Impact | Shearing/Rubbing |

| Best For Particle Size | Coarse to Micron Range | Sub-Micron to Nano Range |

| Typical Scale | Large-Volume, Continuous | Smaller Batch Sizes |

| Feed Size | Large, Coarse Material | Requires Pre-Milled, Fine Feed |

| Grinding Speed | Slower | Up to 10x Faster for Fine Grinding |

Still unsure which mill is right for your project? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment, including ball mills and attrition mills, to meet your specific grinding and material processing needs.

Let us help you achieve your target particle size with maximum efficiency. Contact our team today for a personalized consultation and discover the KINTEK difference in laboratory performance.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- How does a high-energy planetary ball mill facilitate the synthesis of sulfide glassy electrolytes? Achieve Amorphization