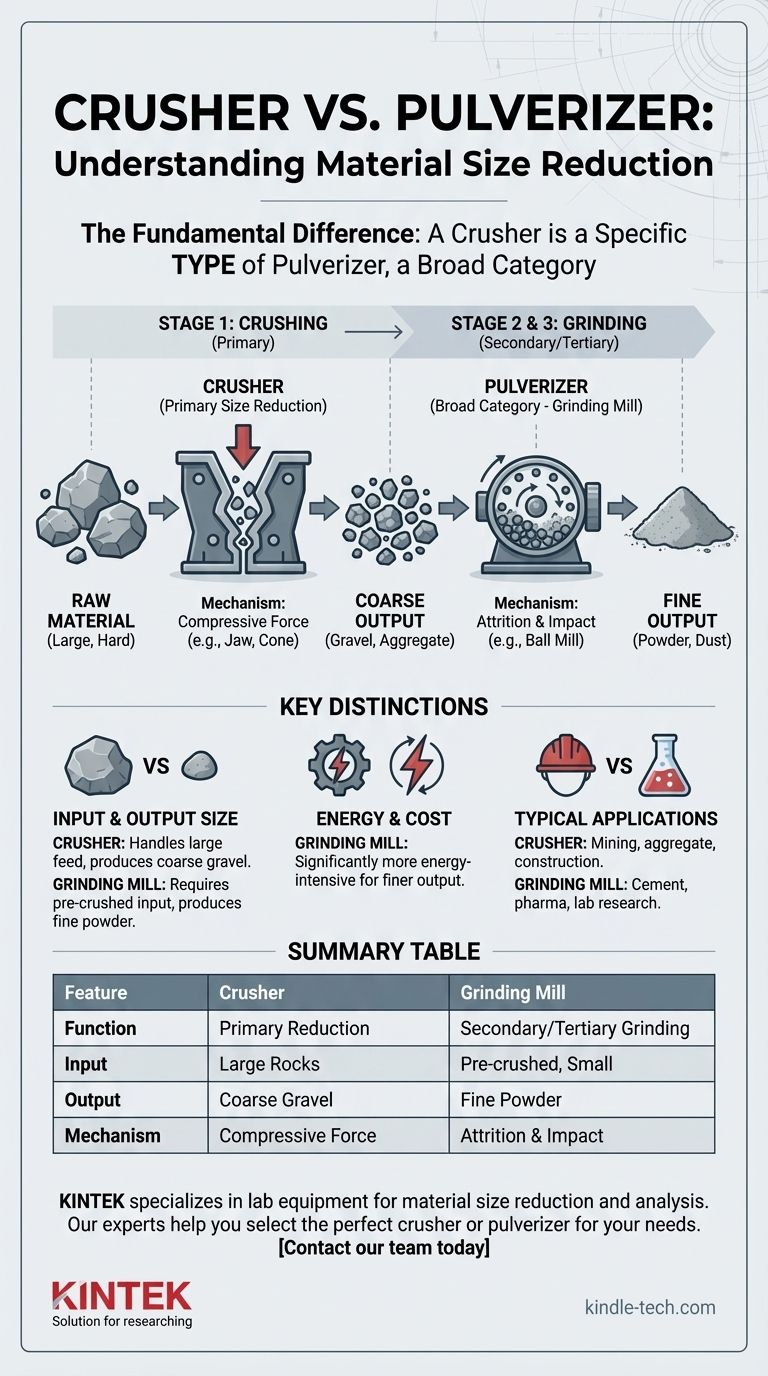

The fundamental difference is not one of opposition, but of classification. A pulverizer is a broad category of machine designed for material size reduction. A crusher is a specific type of pulverizer engineered for the initial, coarse breakdown of large, hard materials.

The core distinction lies in the stage of reduction. A crusher performs the primary task of breaking large rocks into smaller gravel, while other types of pulverizers, like grinding mills, perform the secondary and tertiary task of turning that gravel into fine powder.

What is a Pulverizer? The Broad Category of Size Reduction

A Tool for Disintegration

A pulverizer is any mechanical device designed to break down solid materials into smaller pieces. The term encompasses a wide family of equipment used across mining, construction, recycling, and manufacturing.

The Three Main Types

The pulverizer family is generally broken into three functional groups. Each is designed for a different phase of size reduction.

These groups are crushers, impactors, and grinding mills. Understanding the role of each is key to selecting the right equipment.

The Role of the Crusher: Primary Size Reduction

The First Stage of the Process

A crusher is the heavy-duty machine used at the very beginning of the size reduction process. Its sole purpose is to handle large, often raw, and highly durable materials like rock, ore, and concrete.

How Crushers Work

Crushers use immense compressive force to break material. Common types, like jaw crushers or cone crushers, squeeze the material between two hard surfaces until it fractures. This is a brute-force mechanical action.

The Output: Coarse Materials

The output from a crusher is not a fine powder. Instead, it produces smaller rocks, gravel, or coarse aggregate. While some dust is created as a byproduct, the primary goal is to get the material to a manageable, intermediate size.

Beyond Crushing: Fine Grinding with Other Pulverizers

The Goal of Fine Particles

Many industrial processes, from cement production to pharmaceuticals, require a fine, consistent powder, not coarse gravel. This is where other types of pulverizers become necessary.

Introducing Grinding Mills

Grinding mills are a type of pulverizer that takes the smaller, crushed material and reduces it further into a fine or ultrafine powder. They represent the secondary or tertiary stage of reduction.

The Mechanism: Attrition and Impact

Unlike the compressive force of crushers, mills use principles like attrition (particles rubbing against each other) and high-velocity impact. A ball mill, for example, tumbles the material with steel balls, grinding it down into a fine dust.

Understanding the Trade-offs: Crusher vs. Grinding Mill

Input Material Size

A crusher is built to accept very large feed sizes, measured in feet or inches. A grinding mill cannot handle this; it requires pre-crushed material, typically no larger than a half-inch, as its input.

Desired Output Size

This is the most critical distinction. If you need gravel or small stones, you need a crusher. If you need a sand-like or flour-like powder, you need a grinding mill.

Energy and Operational Costs

As a rule, the finer the final particle size, the more energy is required. Grinding material into a fine powder is significantly more energy-intensive and costly than simply crushing it into aggregate.

Making the Right Choice for Your Application

Choosing the correct machine requires you to define your starting material and your desired end product. It's a two-step process, not an either-or choice.

- If your primary focus is breaking large rocks for aggregate or site fill: You need a crusher for primary reduction.

- If your primary focus is producing a fine powder for manufacturing: You need a crusher for primary reduction followed by a grinding mill for secondary reduction.

- If you are simply looking for a "pulverizer": You must first define your input and output size to determine which specific type of pulverizer (crusher, mill, etc.) is right for the job.

Ultimately, understanding the sequence of size reduction is more important than memorizing definitions.

Summary Table:

| Feature | Crusher | Grinding Mill |

|---|---|---|

| Primary Function | Primary size reduction (coarse) | Secondary/Tertiary grinding (fine) |

| Input Material Size | Large (feet/inches) | Pre-crushed, small (e.g., < 0.5 inch) |

| Output Material Size | Gravel, aggregate, small rocks | Fine or ultra-fine powder |

| Mechanism | Compressive force (e.g., jaw, cone) | Attrition and impact (e.g., ball mill) |

| Typical Application | Mining, construction, aggregate production | Cement, pharmaceuticals, fine powder manufacturing |

Still unsure which equipment is right for your material processing needs?

KINTEK specializes in lab equipment and consumables, serving laboratory needs for material size reduction and analysis. Our experts can help you select the perfect crusher or pulverizer to achieve your desired particle size efficiently.

Contact our team today for a personalized consultation and discover how our solutions can enhance your lab's productivity and precision!

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of mechanical mixing equipment? Optimize C-SiC-B4C Composite Homogeneity

- What is the primary function of a ball mill in magnesium production? Optimize Pretreatment for Efficiency

- What is a ball mill used in pharmaceutical industry? Achieve Superior Particle Size Reduction for Drug Efficacy

- What is the diameter of the balls in a ball mill? Optimize Your Grinding Efficiency with the Right Size

- What is the role of a mechanical rotating ball mill in Li-C anode preparation? Optimize Surface Coating & Conductivity

- What are 5 uses of hammer mill? Unlock Versatile Size Reduction for Your Industry

- Why is grinding equipment used for sulfur-carbon solid-state battery cathodes? Achieve Peak Conductivity

- What is the role of laboratory grinding equipment and high-precision sieving systems? | Boost Sludge Pretreatment