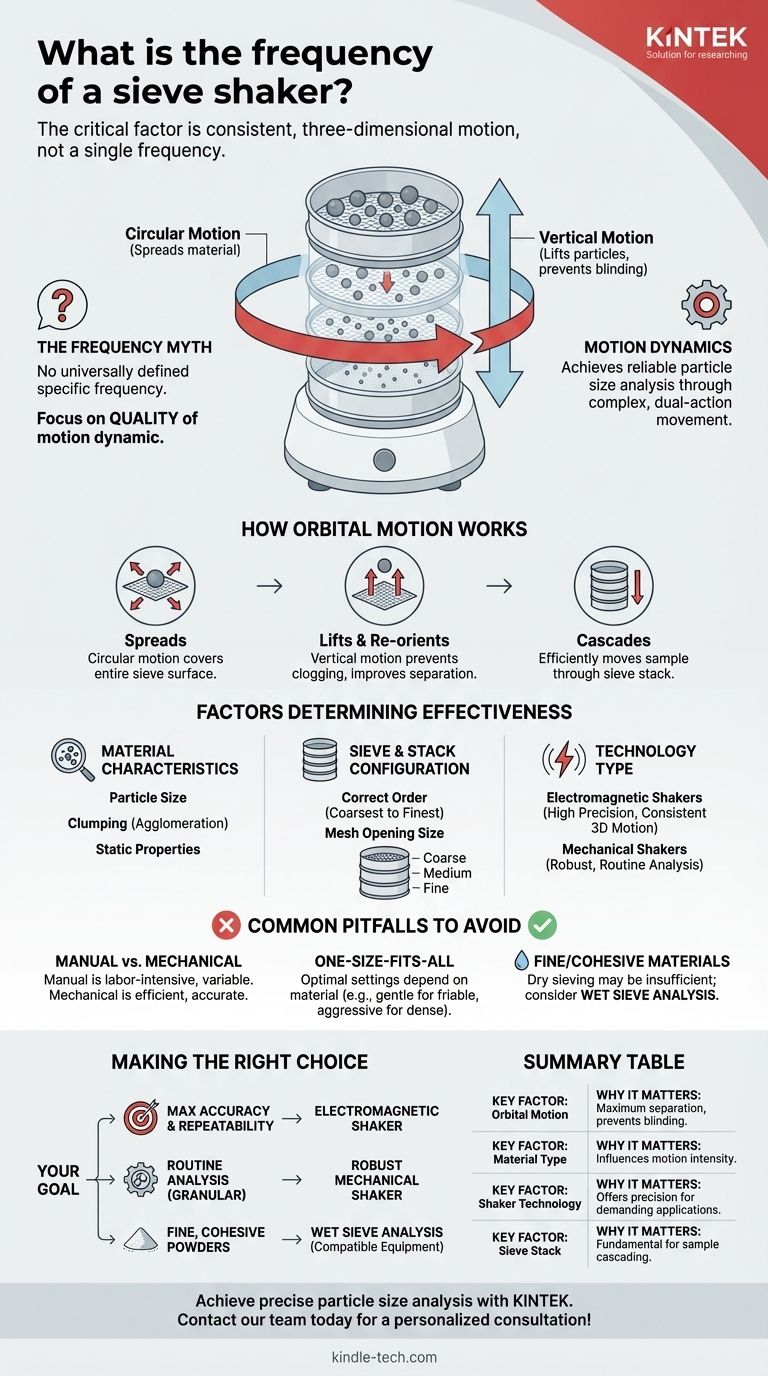

While a specific frequency is not universally defined, the critical factor for a sieve shaker's performance is its ability to produce a consistent, three-dimensional motion. This action ensures particles are repeatedly tested against the sieve openings for accurate and efficient separation. The focus is less on a single frequency value and more on the quality and type of the shaking dynamic.

The effectiveness of a sieve shaker is not determined by its frequency alone, but by its ability to generate a combined circular and vertical (orbital) motion. This complex movement is what ensures every particle has the maximum opportunity to pass through the correct sieve mesh, leading to reliable particle size analysis.

Beyond Frequency: The Importance of Motion Dynamics

The true measure of a sieve shaker is the quality of its motion. A simple back-and-forth vibration is insufficient for precise particle analysis.

The Optimal Orbital Motion

The most effective action for particle separation is orbital motion. This is a specific, three-dimensional movement that combines a horizontal, circular motion with a vertical, tapping motion.

The circular motion spreads the material across the entire surface of the sieve. The vertical motion lifts the particles, preventing the mesh from getting clogged (a problem known as "blinding") and re-orienting the particles to try passing through the openings again.

How This Motion Achieves Separation

This dual-action movement ensures that particles don't just sit in one place. It keeps the entire sample agitated and moving, maximizing the probability that each particle will encounter a mesh opening in an orientation that allows it to pass through.

This process continues down a stack of sieves, which are arranged with the largest openings on top and the smallest on the bottom. The orbital motion efficiently cascades the sample through the layers.

The Role of Mechanical Design

A sieve shaker's design is engineered to produce this specific motion. It consists of a power unit connected to a cradle that holds the stack of sieves.

The cradle is often mounted on shock-absorbing rods and pivots, allowing the power unit to translate its energy into the required orbital path, ensuring the entire sieve stack moves as a single, inflexible unit.

Factors That Determine Sieving Effectiveness

Achieving accurate results depends on more than just the shaker itself. The characteristics of your material play a crucial role.

Material Characteristics

The nature of the material being analyzed heavily influences the process. Key factors include the minimum particle size you need to separate, the material's tendency to clump together (agglomerate), and any static electric properties that may cause particles to stick to the mesh.

Sieve and Stack Configuration

The analysis relies on a stack of precision test sieves. Each sieve is composed of a stainless steel or brass frame holding a woven-wire mesh with a specific opening size, ranging from millimeters down to microns. The correct stacking order, from coarsest to finest, is fundamental to the separation process.

Technology Type

For applications demanding the highest levels of precision and repeatability, electromagnetic sieve shakers are often recommended. These units use electromagnetic pulses to generate a very consistent and controllable 3D motion, offering greater accuracy than some purely mechanical models.

Common Pitfalls to Avoid

While mechanical shakers are a major improvement over manual methods, understanding their limitations is key to achieving reliable data.

Manual Sieving vs. Mechanical Shaking

Replacing manual hand sieving with a mechanical shaker provides significant advantages in efficiency, accuracy, and flexibility. Manual methods are prone to operator-induced variability and are far more labor-intensive.

Not a One-Size-Fits-All Solution

There is no single set of shaking parameters (including motion intensity and duration) that works for all materials. The optimal settings depend entirely on the material's properties. A gentle motion may be needed for friable particles, while a more aggressive action might be required for dense, agglomerated powders.

Limitations with Certain Materials

For very fine powders or materials that are heavily affected by static or clumping, dry sieving may be insufficient. In these cases, wet sieve analysis is necessary, where a liquid is used to help disperse the particles and carry them through the mesh.

Making the Right Choice for Your Goal

To ensure reliable particle analysis, you must match the sieving method to your material and your analytical objectives.

- If your primary focus is maximum accuracy and repeatability: Select an electromagnetic shaker that offers precise control over the orbital motion.

- If your primary focus is routine analysis of granular or coarse materials: A robust mechanical shaker that provides a consistent orbital motion is a highly effective and reliable choice.

- If your primary focus is analyzing fine, cohesive, or static-prone powders: Plan for wet sieve analysis and ensure your shaker is compatible with the necessary equipment.

Ultimately, achieving accurate particle size analysis relies on applying the correct type of controlled motion for your specific material.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Orbital Motion | Combines circular and vertical movement for maximum particle separation and prevents mesh blinding. |

| Material Type | Influences the required motion intensity; fine powders may need gentler action than coarse granules. |

| Shaker Technology | Electromagnetic shakers offer superior precision and repeatability for demanding applications. |

| Sieve Stack Configuration | Correct order (coarsest to finest) is fundamental for cascading the sample through the layers. |

Achieve precise and repeatable particle size analysis with the right equipment. The key to reliable results is a sieve shaker that delivers consistent, three-dimensional orbital motion tailored to your specific material. At KINTEK, we specialize in high-quality lab equipment, including mechanical and electromagnetic sieve shakers, designed to meet the diverse needs of laboratories. Whether your focus is routine analysis or maximum accuracy, our experts can help you select the ideal solution. Enhance your lab's efficiency and data quality – contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- Which sieving instrument for fine aggregates? Choose the Right Sieve Shaker for Accurate Gradation

- What is the critical function of high-precision sieving for aluminum powders? Ensure Uniform Composite Integrity

- What are the disadvantages of a sieve shaker? Key Limitations for Accurate Particle Sizing

- Why is a benchtop shaker essential during the biosorption experiments of palladium ions (Pd2+)? Maximize Your Ion Yield

- What is the function of a mechanical shaker in zirconium-hafnium solvent extraction? Master Precise Chemical Separation

- What is the importance of industrial-grade sieving systems in food waste fermentation? Enhance Yield & Protect Equipment

- Why is a sieve shaker important? Automate Particle Analysis for Accurate, Repeatable Results

- What precautions should be taken during sieve analysis? Ensure Accurate & Repeatable Particle Size Results