In simple terms, the frequency of a vibrating screen is the speed of its vibration, measured as the number of cycles it completes per minute (RPM) or per second (Hz). While typical screens operate between 750 and 1000 RPM, specialized high-frequency units can run as fast as 3600 RPM to handle fine, dry materials.

The critical insight is that frequency is not a standalone value. It is one part of a crucial balance with amplitude (the size of the vibration) to generate the right G-force, which dictates how effectively material is separated.

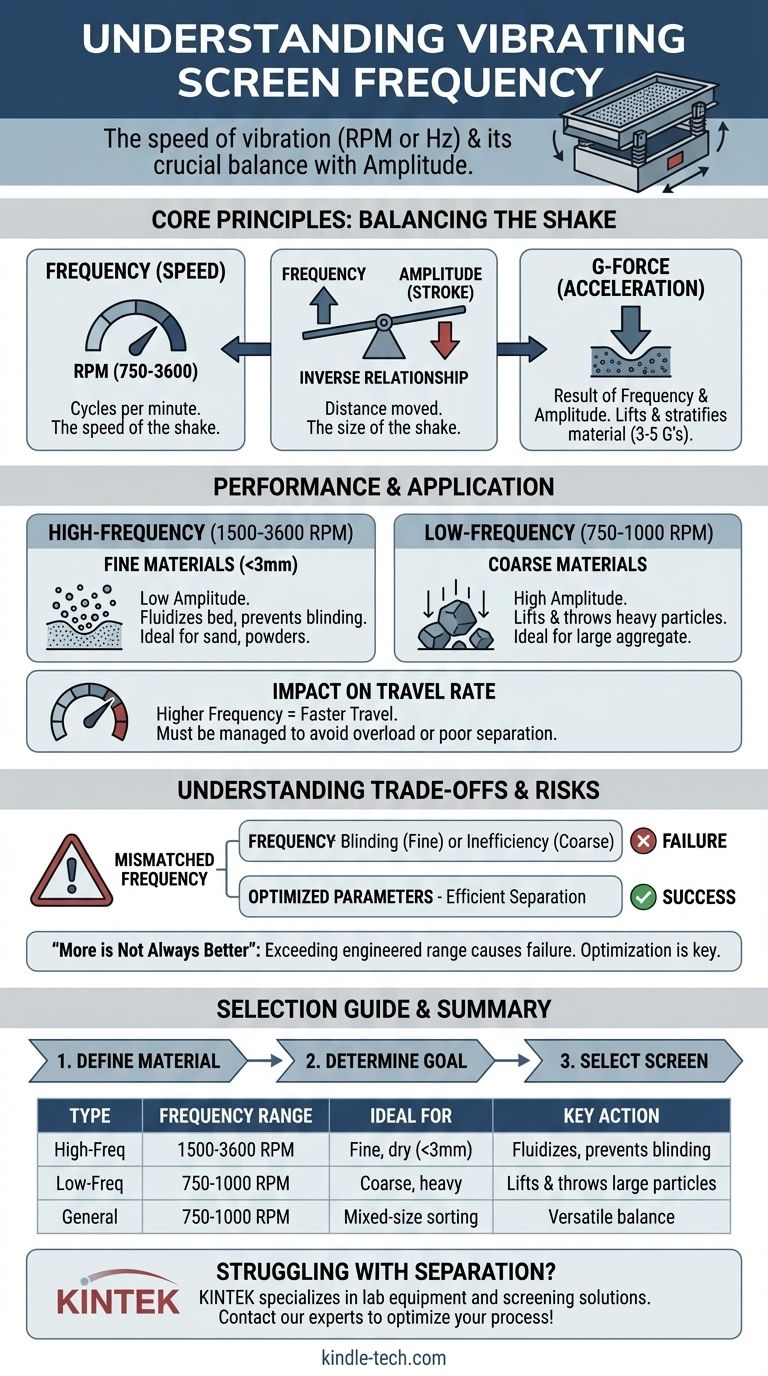

The Core Principles of Screen Vibration

To understand frequency, you must see it as part of a system. The goal of a vibrating screen is to throw material up and forward, allowing particles to stratify and giving smaller particles a chance to pass through the screen opening.

Defining Frequency

Frequency refers to how often the screen completes a full vibrational movement. It is the "speed" of the shake.

This is most commonly expressed in Revolutions Per Minute (RPM), which directly relates to the operational speed of the motor or exciter mechanism driving the screen.

The Role of Amplitude (Stroke)

Amplitude, or stroke, is the distance the screen deck moves during one vibration. It is the "size" of the shake.

Frequency and amplitude have an inverse relationship. A machine designed for high frequency will have a low amplitude, while a low-frequency machine will have a high amplitude. You cannot simply increase one without affecting the other.

The Critical Factor: G-Force

G-force is the acceleration applied to the material particles by the screen's motion. It is the direct result of combining frequency and amplitude.

This force is what overcomes gravity and lifts the material off the screen cloth. Proper G-force (typically 3-5 G's) is essential to spread the material, stratify the particle bed, and achieve efficient separation.

How Frequency Dictates Performance

The correct frequency is determined entirely by the material being processed and the desired cut size. There is no single "best" frequency; there is only the right frequency for the application.

High-Frequency for Fine Materials

For separating fine, dry materials like sand or powders (typically under 3mm), high-frequency (1500-3600 RPM) vibration is necessary.

The low amplitude and high-speed vibrations are essential to break the surface tension and static bonds between small particles. This action "fluidizes" the material bed, allowing fine particles to easily find the screen openings and preventing screen blinding (clogging).

Low-Frequency for Coarse Materials

For separating heavy, coarse materials like large rocks or primary aggregates, a low-frequency (750-1000 RPM) approach is required.

These applications need a high-amplitude stroke to physically lift and throw the heavy, large particles forward. A high-frequency vibration would simply shake the material in place without providing the force needed to move and stratify it effectively.

The Impact on Travel Rate

Frequency also influences how quickly material moves across the screen deck. Generally, a higher frequency results in a faster travel rate.

This must be carefully managed. If material travels too fast, it doesn't have enough time on the screen for efficient separation. If it travels too slowly, it can overload the screen and reduce capacity.

Understanding the Trade-offs

Selecting the wrong operating parameters can lead to significant operational failures. The goal is optimization, not maximization.

The Risk of Mismatched Frequency

Using a low-frequency screen for fine materials will result in immediate screen blinding and poor separation efficiency.

Conversely, using a high-frequency screen for heavy, coarse material will fail to move the material effectively and could cause premature structural fatigue on a machine not designed for that impact.

Why "More is Not Always Better"

Simply increasing the frequency of a screen is not a universal solution. Doing so without considering the amplitude will alter the G-force and travel rate, often in undesirable ways.

Every screen is engineered to operate within a specific frequency and amplitude range. Exceeding these parameters can lead to component failure and inefficient screening.

Selecting the Right Frequency for Your Application

The choice must be driven by your material and your goal. Consult with the equipment manufacturer to ensure the machine's parameters are set to match your specific needs.

- If your primary focus is fine material separation (e.g., sand, powders, fine minerals): Your solution lies in high-frequency, low-amplitude screens designed to prevent blinding and fluidize the material.

- If your primary focus is coarse scalping or heavy-duty sizing (e.g., large aggregate, riprap): You require a low-frequency, high-amplitude machine with the power to throw and stratify heavy material.

- If your primary focus is general-purpose sorting with mixed sizes: A conventional inclined screen operating in a standard range (750-1000 RPM) offers the most versatile balance of throw and vibration.

Ultimately, matching the screen's frequency and stroke to the material's characteristics is the key to achieving efficient and profitable separation.

Summary Table:

| Vibration Type | Typical Frequency Range | Ideal For Material | Key Action |

|---|---|---|---|

| High-Frequency | 1500 - 3600 RPM | Fine, dry materials (< 3mm) | Fluidizes bed, prevents blinding |

| Low-Frequency | 750 - 1000 RPM | Coarse, heavy materials | Lifts and throws large particles |

| General Purpose | 750 - 1000 RPM | Mixed-size sorting | Versatile balance of throw and vibration |

Struggling with screen blinding or inefficient separation? The right frequency and amplitude settings are critical for your material. KINTEK specializes in lab equipment and consumables, including screening solutions for laboratory needs. Our experts can help you select and optimize the right vibrating screen for your specific application, ensuring peak performance and efficiency. Contact our specialists today to discuss your requirements and enhance your separation process!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- What are the disadvantages of sieve shaker machine? Key Limitations for Accurate Particle Analysis

- Why is the use of high-precision analytical sieve shakers necessary for LPBF? Ensure Perfect Metal Powder Consistency

- Which types of diameter or size can be determined using sieve shaker method for the given granular sample? A Guide to the 38 µm to 4 mm Range

- What is the significance of using a laboratory constant-temperature shaker in corrosion inhibitor biodegradation study?

- What role does a constant temperature shaker play in evaluating boron removal? Ensure Data Accuracy in Brine Adsorption

- What role does a constant-temperature shaker play in batch adsorption experiments? Key Insights for Lab Efficiency

- What is the purpose of a shaker in Zircon powder coating? Achieve Dense, Bubble-Free NTP Reactor Electrodes