At its core, a vibratory sieve shaker is a laboratory instrument designed to perform particle size analysis. It automates the process of separating a granular material into different size fractions, providing a clear and repeatable measurement of the particle distribution within a sample. This is crucial for quality control and research across countless industries.

A sieve shaker replaces inconsistent, labor-intensive manual sieving with a mechanical process that delivers superior accuracy, efficiency, and repeatability. Its function is to provide an objective, data-driven understanding of a material's physical properties by precisely sorting its constituent particles by size.

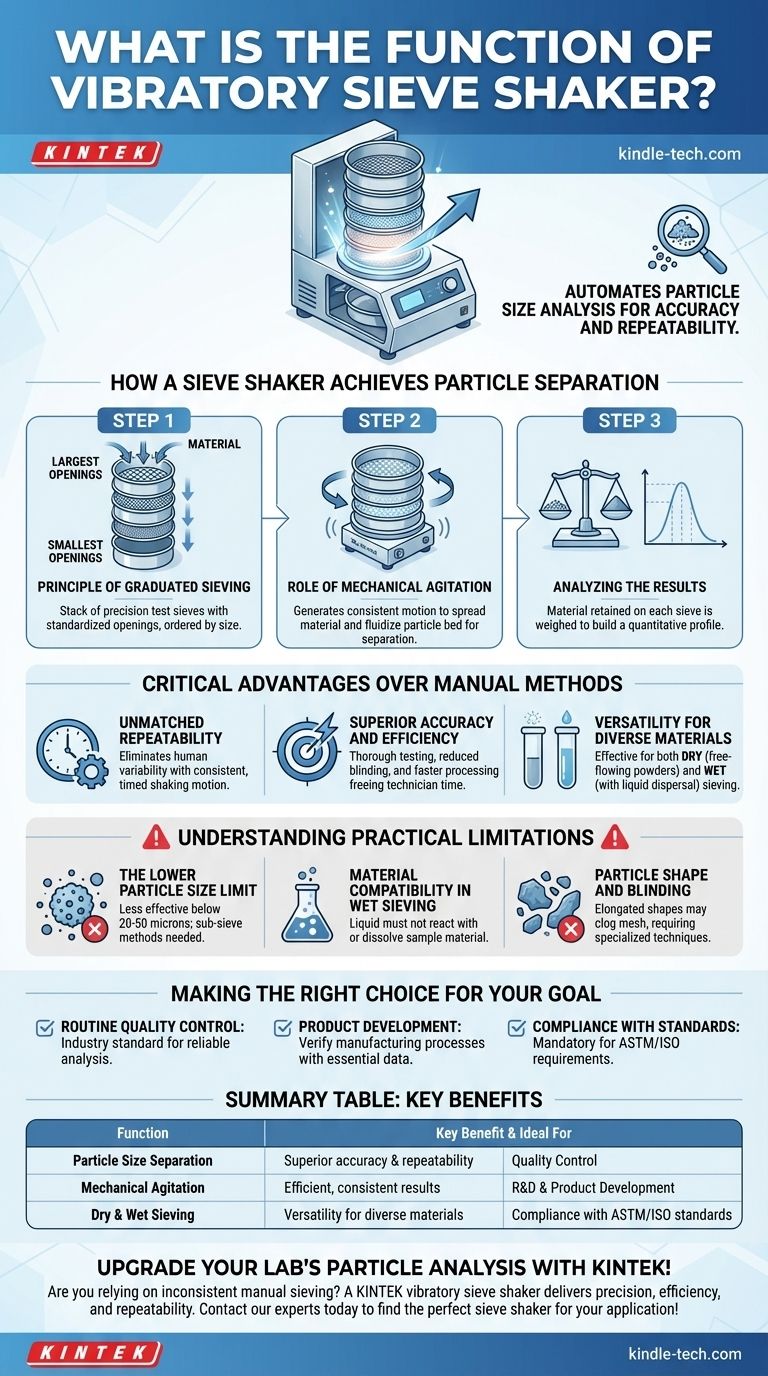

How a Sieve Shaker Achieves Particle Separation

The function of a sieve shaker is rooted in a simple, reliable mechanical process. It combines a standardized set of tools with controlled motion to ensure every analysis is consistent.

The Principle of Graduated Sieving

The foundation of the system is a stack of test sieves. These are precision instruments with a screen of woven wire mesh that has openings of a specific, certified size.

The sieves are stacked in order of aperture size, with the sieve having the largest openings on top and the one with the smallest openings at the bottom. A solid collection pan is placed below the final sieve.

The Role of Mechanical Agitation

Once a material sample is placed in the top sieve, the shaker is activated. It generates a consistent, often three-dimensional, throwing motion.

This agitation serves two purposes: it spreads the material across the mesh surface and fluidizes the particle bed, giving each particle the opportunity to pass through an aperture if it is small enough. Particles continue to fall through the stack until they are retained by a sieve with openings smaller than their own diameter.

Analyzing the Results

After a set time, the machine is stopped. The material retained on each individual sieve is then weighed.

This data allows the operator to build a particle size distribution curve, which provides a quantitative profile of the sample, detailing the percentage of material that falls within each size range.

The Critical Advantages Over Manual Methods

While manual sieving is possible, a mechanical shaker provides benefits that are essential for any professional setting where data integrity is important.

Unmatched Repeatability

A machine performs the exact same shaking motion for the exact same duration every time. This eliminates the human variability inherent in manual methods, ensuring results are comparable day-to-day and between different operators.

Superior Accuracy and Efficiency

The shaker's consistent energy input ensures that particles are thoroughly tested against each sieve opening, reducing the chance of blinding (clogging) and providing a more accurate separation. It also processes samples significantly faster, freeing up valuable technician time.

Versatility for Diverse Materials

Modern sieve shakers are highly flexible. They can perform dry sieving for free-flowing powders and granules or be adapted for wet sieving, which uses a liquid to help disperse fine particles that might otherwise agglomerate.

Understanding the Practical Limitations

While powerful, a vibratory sieve shaker is not the universal solution for all particle analysis. Understanding its limitations is key to generating reliable data.

The Lower Particle Size Limit

Vibratory shakers are most effective for coarse materials down to relatively fine powders. However, for extremely fine particles, typically below 20-50 microns, the physical interactions between particles can prevent them from passing through the mesh effectively.

For these sub-sieve materials, other methods like air jet sieving or laser diffraction are often more appropriate.

Material Compatibility in Wet Sieving

When performing wet sieve analysis, the chosen liquid (usually water) must not react with or dissolve the sample material. Doing so would alter the particle sizes and invalidate the results.

Particle Shape and Blinding

Elongated or irregularly shaped particles can become lodged in the mesh openings, a phenomenon known as blinding or pegging. While the shaker's motion helps minimize this, certain materials may still require specialized techniques or frequent cleaning to ensure accurate results.

Making the Right Choice for Your Goal

Using a sieve shaker is about applying the right tool to the right problem. Its function is to provide reliable data for specific applications.

- If your primary focus is routine quality control for granular materials: A sieve shaker is the industry standard for cost-effective, reliable, and repeatable analysis.

- If you are developing a new product with specific particle characteristics: This tool provides the essential data to verify your manufacturing process is producing the desired outcome.

- If your primary focus is compliance with industry standards (e.g., ASTM, ISO): Using a certified sieve shaker and test sieves is often a mandatory requirement.

Ultimately, a vibratory sieve shaker transforms particle analysis from a subjective approximation into a precise, data-driven science.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Particle Size Separation | Superior accuracy & repeatability | Quality Control |

| Mechanical Agitation | Efficient, consistent results | R&D & Product Development |

| Dry & Wet Sieving | Versatility for diverse materials | Compliance with ASTM/ISO standards |

Upgrade your lab's particle analysis with KINTEK!

Are you relying on inconsistent manual sieving for your quality control or research? A KINTEK vibratory sieve shaker delivers the precision, efficiency, and repeatability you need for reliable particle size data. Our shakers are designed to meet industry standards and handle a wide range of materials, ensuring your results are accurate and trustworthy.

As your partner in laboratory equipment, KINTEK specializes in providing robust solutions for all your sieving needs. Let us help you enhance your workflow and data integrity.

Contact our experts today to find the perfect sieve shaker for your application!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What are the precautions of sieve shaker? Ensure Accurate Particle Analysis & Protect Your Equipment

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What is the amplitude of a sieve shaker? A Guide to Optimizing Particle Separation

- What is a vibrating sieve shaker? Achieve Accurate and Repeatable Particle Size Analysis

- What role does a laboratory vibrating sieve shaker play in the LiFePO4 powder processing workflow? Ensure Batch Quality