In a ball mill, the grinding media are the balls, beads, or pebbles that physically collide with and break down the material being processed. These media are made from a range of materials—including stainless steel, various ceramics like zirconium oxide, tungsten carbide, and agate—each chosen based on the material to be ground and the desired outcome of the process.

Selecting the right grinding media is as critical as choosing the mill itself. The media's material properties—specifically its hardness, density, and chemical inertness—directly determine the grinding efficiency and, most importantly, the level of contamination introduced into your final sample.

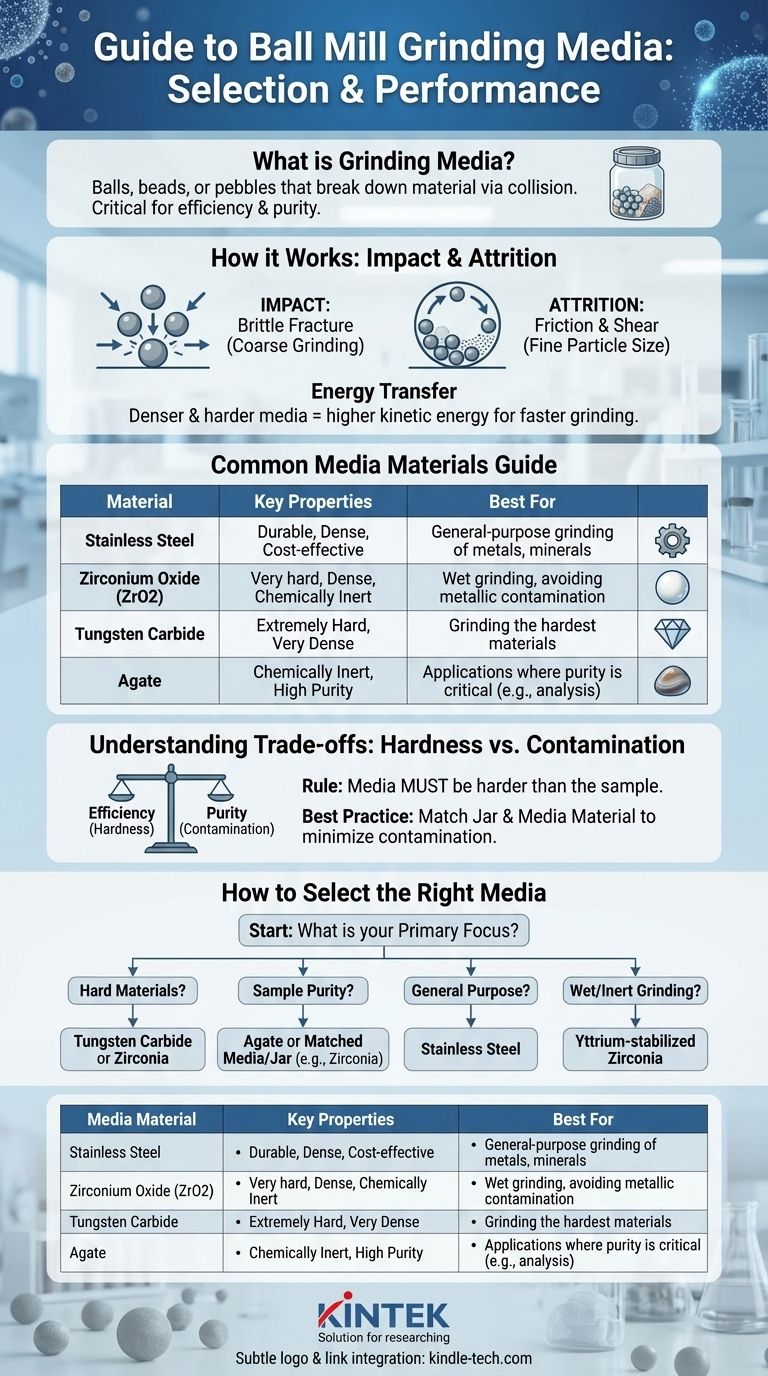

The Role of Grinding Media: More Than Just Crushing

A ball mill works by placing the sample material in a jar along with the grinding media. As the jar rotates or oscillates at high speed, the media cascades and collides, pulverizing the sample through a combination of impact and friction.

The Principle of Impact and Attrition

High-energy impacts from the falling media cause brittle fracturing and coarse grinding. Simultaneously, the friction and shear forces created as the media tumbles against itself and the sample cause attrition, which leads to much finer particle sizes.

Energy Transfer and Grinding Efficiency

The effectiveness of this process hinges on energy transfer. Denser and harder media transfer more kinetic energy upon impact, leading to faster and more efficient grinding of tough materials. The size of the media also plays a role, with larger balls providing higher impact and smaller balls providing a finer final grind.

A Guide to Common Grinding Media Materials

The choice of media material is a deliberate engineering decision based on the sample's properties and the analytical goals.

Stainless Steel

Stainless steel is the workhorse of grinding media. It is durable, relatively dense, and cost-effective, making it an excellent choice for general-purpose grinding of many materials, including metals and some minerals.

Zirconium Oxide (Ceramic)

Often stabilized with yttrium, zirconium oxide (ZrO2) is a high-performance ceramic. It is exceptionally hard, dense, and highly wear-resistant. Its chemical inertness and non-corrosive nature make it the preferred choice for wet grinding and applications where metallic contamination must be avoided.

Tungsten Carbide

For grinding extremely hard materials, tungsten carbide is the superior choice. It is significantly harder and denser than even zirconium oxide, providing the maximum possible impact energy. However, it is also more expensive and can introduce tungsten contamination.

Agate

When sample purity is the absolute priority, agate is the ideal media. It is a form of microcrystalline quartz that is chemically inert and introduces very minimal contamination. Its primary limitation is its lower hardness and density, making it unsuitable for grinding very hard substances.

Other Specialized Media

Materials like brass, bronze, and non-sparking lead serve niche applications. For instance, non-sparking media is a critical safety requirement when milling potentially explosive or volatile materials. Flint pebbles are a traditional, low-cost option for less demanding applications.

Understanding the Trade-offs: Hardness vs. Contamination

Choosing the right media involves balancing two competing factors: the need for efficient grinding and the need for sample purity.

The Rule of Hardness

A fundamental principle of milling is that the grinding media must be significantly harder than the material being ground. If the sample is harder than the media, you will wear down your media, introduce massive contamination, and fail to effectively grind your sample.

The Inevitability of Contamination

All grinding processes introduce some level of contamination as the media and jar inevitably wear down. The goal is not to achieve zero contamination—which is impossible—but to minimize it and control its composition.

Matching Jar and Media Material

A best practice for controlling contamination is to use a grinding jar made from the same material as your media. Using zirconia balls in a zirconia jar, for example, ensures that any contamination introduced is simply more zirconia, which can often be ignored or easily accounted for in subsequent analysis.

How to Select the Right Media for Your Application

Your choice should be guided by a clear understanding of your primary objective.

- If your primary focus is grinding very hard materials: Choose a media harder than your sample, such as tungsten carbide or zirconium oxide.

- If your primary focus is minimizing sample contamination: Use agate media for ultimate purity, or match your media material to your jar material (e.g., zirconia balls in a zirconia jar).

- If your primary focus is cost-effective, general-purpose grinding: Stainless steel is often the most practical and versatile starting point.

- If you are performing wet grinding or need chemical inertness: Yttrium-stabilized zirconium oxide is the industry standard due to its non-corrosive and wear-resistant properties.

By understanding the properties of your grinding media, you transform milling from a brute-force process into a controlled and precise technique.

Summary Table:

| Media Material | Key Properties | Best For |

|---|---|---|

| Stainless Steel | Durable, cost-effective, good density | General-purpose grinding of metals, minerals |

| Zirconium Oxide (ZrO2) | Very hard, dense, chemically inert, wear-resistant | Wet grinding, avoiding metallic contamination |

| Tungsten Carbide | Extremely hard and dense | Grinding the hardest materials |

| Agate | Chemically inert, minimal contamination | Applications where sample purity is critical |

| Specialized (e.g., Lead) | Non-sparking | Milling explosive or volatile materials |

Struggling to choose the right grinding media for your specific application?

The wrong choice can lead to inefficient grinding, excessive contamination, and wasted time. KINTEK specializes in lab equipment and consumables, offering expert guidance and a full range of high-quality grinding media and jars to perfectly match your material and purity requirements.

Let our experts help you achieve optimal results. Contact us today to discuss your application and find the ideal solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Nature Agate Mortar and Pestle for Grinding and Mixing

People Also Ask

- What is the primary function of mechanical grinding equipment in PHBV production? Optimize Feedstock for Maximum Yield

- What is the working principle of a vertical ball mill? Achieve Efficient Fine Grinding with Agitated Media

- What are the advantages of using a high-shear homogenizer for BED/GMA coatings? Achieve Superior Nano-Dispersion

- What types of contamination and changes in composition can occur during crushing and grinding? Protect Your Sample Integrity

- Why is a grinding mill necessary during cement clinker pulverization? Unlock Reactivity and Strength

- What is the preventive maintenance of ball mill? Ensure Maximum Uptime and Reliability

- What is the role of a 3D powder mixer in the preparation of metal-ceramic composites? Achieve Perfect Homogeneity

- What is the critical role of high-energy ball mills in UHTC powders? Enhancing Sintering Efficiency and Reactivity