The rotational speed of a ball mill cylinder is the single most critical factor in determining its grinding efficiency. The speed dictates the motion of the grinding media—the balls—and this motion is what generates the forces needed to break down material. If the speed is wrong, you will either waste immense energy on an inefficient process or fail to grind the material at all.

The goal is not to rotate the mill as fast as possible. Instead, the optimal speed is a carefully calculated percentage of the mill's "critical speed," designed to create a cascading and tumbling motion that maximizes both impact and friction for effective grinding.

The Physics of Grinding: Gravity vs. Centrifugal Force

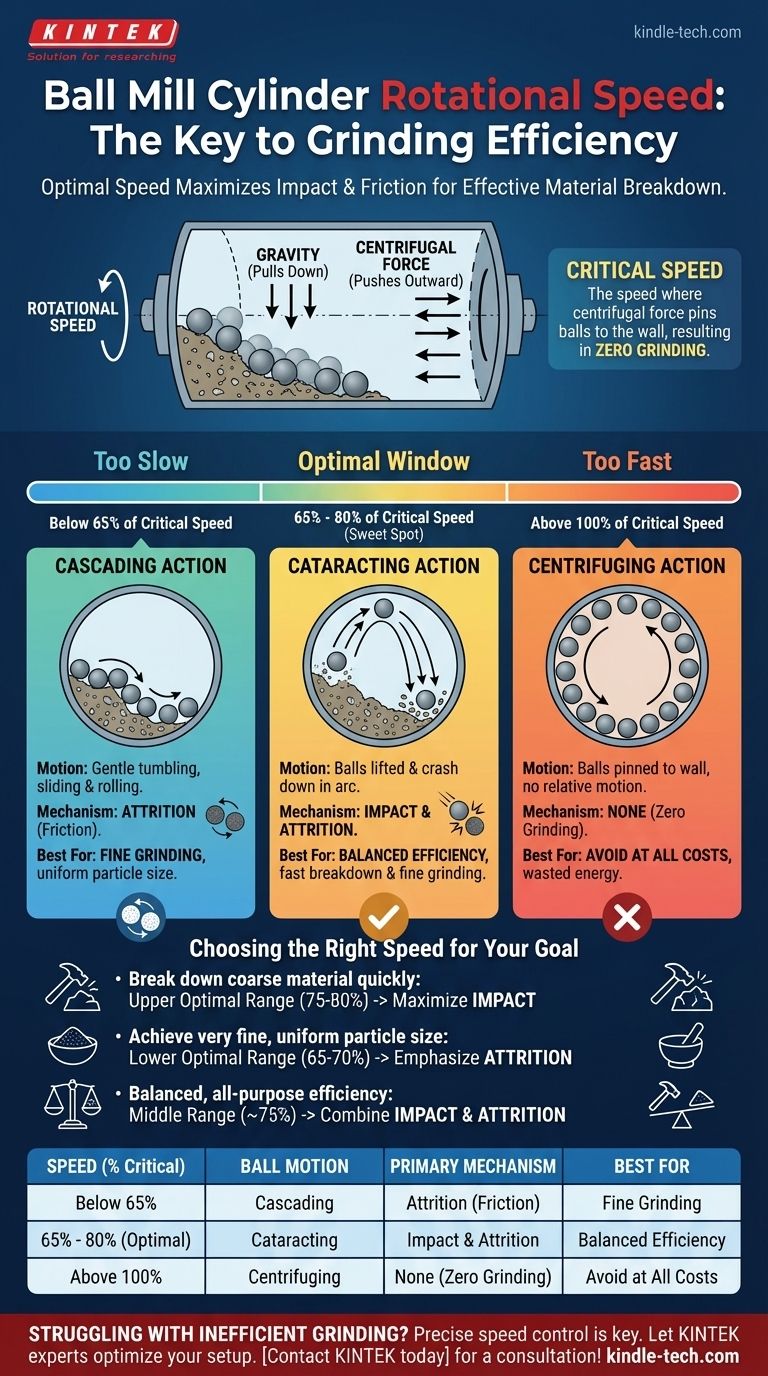

The behavior of the grinding media inside the mill is a constant battle between two primary forces. Gravity pulls the balls down, while the rotation of the cylinder creates a centrifugal force that pushes them outward against the mill wall. The rotational speed determines which force wins.

What is "Critical Speed"?

Critical speed is the theoretical rotational speed at which the centrifugal force precisely overcomes gravity. At this speed, the outermost layer of grinding balls will be pinned against the inner wall of the cylinder for the entire rotation.

These balls never fall. They simply travel in a circle with the mill's shell. When this happens, there is no tumbling, no impact, and therefore, no grinding takes place. Operating at or above the critical speed is a state of zero efficiency.

The Optimal Operating Speed

For effective grinding, the mill must be operated at a speed below its critical speed. The universally accepted range for optimal performance is between 65% and 80% of the critical speed.

This specific window ensures the balls are carried up the side of the mill, detach near the top, and fall onto the material at the bottom. This motion creates the two essential mechanisms for size reduction.

The Three Regimes of Mill Operation

The speed you choose creates one of three distinct types of motion inside the mill, each with a different outcome.

1. Too Slow: Cascading Action

At low speeds (typically below 65% of critical speed), the balls tumble over one another, primarily staying in the bottom half of the mill. This gentle sliding and rolling motion is called cascading.

The primary grinding mechanism here is attrition, or friction, as particles are rubbed between the moving balls. While this is effective for producing a very fine product, the process is slow and lacks the powerful impact forces needed to break down larger particles efficiently.

2. Too Fast: Centrifuging Action

At speeds at or above 100% of the critical speed, the grinding media centrifuges. The balls are held firmly against the mill's inner wall by centrifugal force.

There is no relative motion between the balls and the cylinder. As a result, no impact or attrition occurs. This is the least effective state, resulting in zero grinding and wasted energy.

3. The "Sweet Spot": Cataracting Action

Within the optimal 65-80% window, the mill achieves cataracting motion. The balls are carried high up the side of the mill and then break free, following a parabolic arc to crash down onto the material below.

This is the most efficient mode of operation because it combines powerful impact forces from the falling balls with the continuous attrition from the tumbling charge. This dual-action grinding is ideal for most applications, delivering fast and effective particle size reduction.

Understanding the Trade-offs

Choosing a speed even within the optimal window involves balancing competing goals. The right choice depends on your starting material and desired final product.

Efficiency is Paramount

Operating outside the optimal window—either too slow or too fast—directly leads to wasted energy, increased operational costs, and significantly longer grinding times. Incorrect speed is the most common source of poor ball mill performance.

Fine Grinding vs. Coarse Grinding

A speed at the lower end of the optimal range (around 65-70%) favors cascading and attrition. This is better for producing a finer, more uniform final product if your starting material is already relatively small.

A speed at the higher end (around 75-80%) maximizes cataracting and impact. This is more effective for quickly breaking down larger, coarser feed material.

How to Set the Right Speed for Your Goal

Your target speed is not an arbitrary number; it is a strategic choice based on the physics of grinding.

- If your primary focus is breaking down coarse material quickly: Operate in the upper range of the optimal window (75-80% of critical speed) to maximize powerful impact forces.

- If your primary focus is achieving a very fine, uniform particle size: Operate in the lower range of the optimal window (65-70% of critical speed) to emphasize attrition and friction.

- If your primary focus is balanced, all-purpose efficiency: Aim for the middle of the range (around 75% of critical speed) to achieve a strong combination of impact and attrition.

Controlling the rotational speed is controlling the very nature of the grinding process, transforming it from a random action into a precise engineering task.

Summary Table:

| Speed (% of Critical Speed) | Ball Motion | Primary Grinding Mechanism | Best For |

|---|---|---|---|

| Below 65% | Cascading | Attrition (Friction) | Fine Grinding |

| 65% - 80% (Optimal) | Cataracting | Impact & Attrition | Balanced Efficiency |

| Above 100% | Centrifuging | None (Zero Grinding) | Avoid at All Costs |

Struggling with inefficient grinding or inconsistent results? The precise control of your ball mill's rotational speed is the key to unlocking peak performance, reducing energy costs, and achieving your target particle size. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable solutions your laboratory needs for optimal grinding processes. Let our experts help you optimize your setup. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the efficiency of a ball mill is maximum at? Optimize Grinding with the Right Speed

- Why use agate grinding jars for silver vanadium oxide? Ensure Purity in Battery Material Milling

- What are the disadvantages of producing a laboratory sample from a gross sample by crushing and grinding? Avoid Contamination and Data Errors

- Why are high-shear mixing or ultrasonic homogenizers necessary for MMT nanocomposites? Unlock True Nano-Reinforcement

- Why is an agate mortar used for manual grinding? Ensure Purity in LLZO Electrolyte Mixing

- What is the mechanism of a grinding machine? Achieve Superior Precision and Surface Finishes

- What role does grinding equipment play in the chemical stability assessment of Li3InCl6 electrolytes? | Expert Analysis

- What is the function of a 3D motion mixer with WC balls for high-entropy alloys? Ensure Perfect Powder Homogeneity