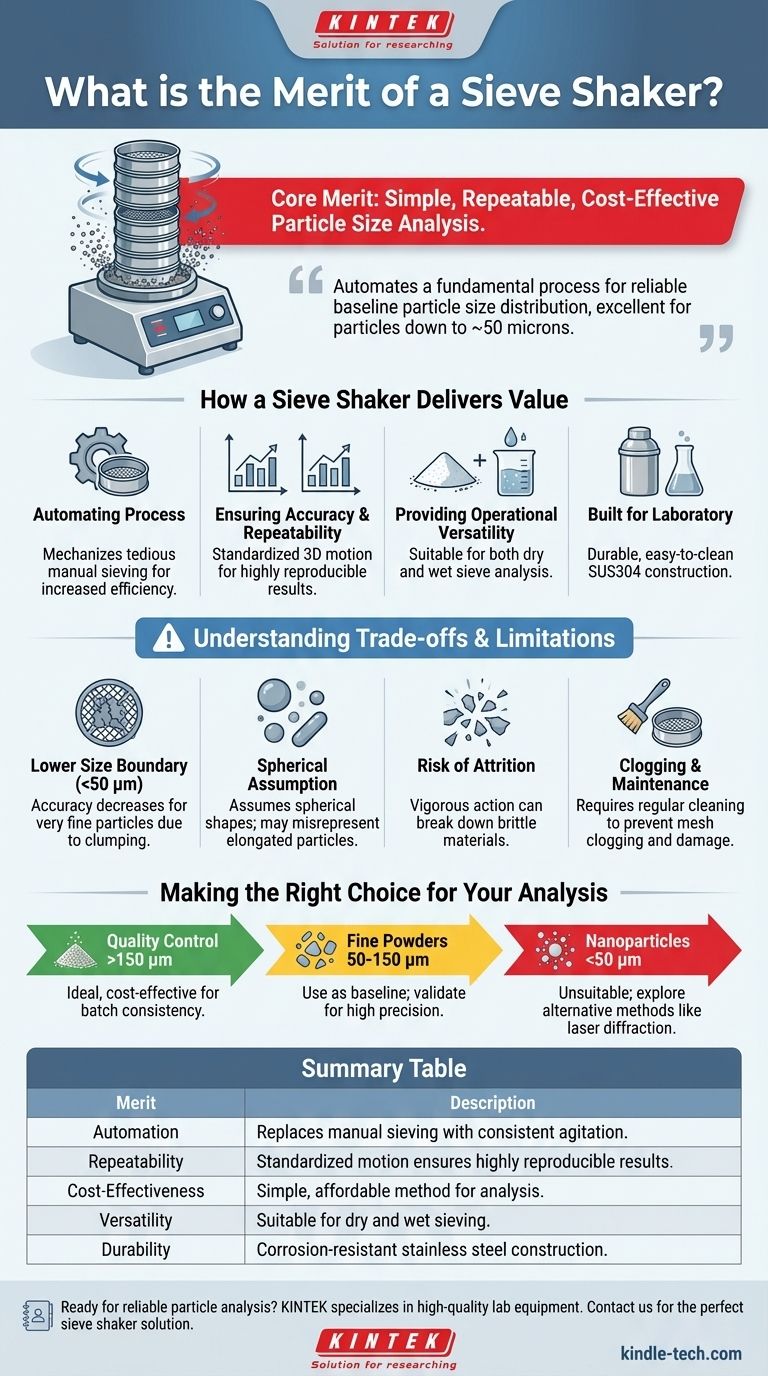

The core merit of a sieve shaker is its ability to provide simple, repeatable, and cost-effective particle size analysis. It automates the foundational process of sieving, replacing inconsistent manual methods with a machine-driven approach that delivers reliable data for quality control and material characterization.

A sieve shaker automates a fundamental process, offering a reliable baseline for particle size distribution. While it excels in simplicity and cost-effectiveness for particles down to about 50 microns, its accuracy is fundamentally limited by particle shape and the physical constraints of the mesh.

How a Sieve Shaker Delivers Value

A sieve shaker’s primary function is to agitate a stack of test sieves, allowing particles to separate by size. This simple mechanism provides several distinct advantages in a laboratory or industrial setting.

Automating a Foundational Process

A sieve shaker mechanizes the tedious and error-prone task of hand sieving. By providing a consistent and vigorous motion, it ensures that particles have the maximum opportunity to pass through the appropriate sieve apertures. This increases efficiency and frees up technician time.

Ensuring Accuracy and Repeatability

The key to any valid analysis is reproducibility. Sieve shakers use a standardized motion, such as a 3D throwing action, to create the same agitating conditions for every test. This removes the variability of manual shaking and leads to highly repeatable and accurate results that can be trusted for quality control.

Providing Operational Versatility

Sieve shakers are not limited to one type of material. They can be used for both dry sieving of free-flowing powders and wet sieve analysis for materials that tend to clump or are not affected by liquid. This flexibility makes them suitable for analyzing everything from coarse aggregates down to fine powders.

Built for a Laboratory Environment

Most laboratory sieve shakers are constructed from durable materials like SUS304 stainless steel. This provides excellent corrosion resistance and a smooth surface that is easy to clean, preventing cross-contamination between samples. Their design often requires minimal installation space, fitting easily into most lab workflows.

Understanding the Trade-offs and Limitations

No instrument is perfect for every application. To use a sieve shaker effectively, you must understand its inherent limitations. These are not flaws in the design but trade-offs rooted in the physical principles of sieving.

The Lower Particle Size Boundary

Sieving becomes increasingly difficult as particles get smaller. Sieve shakers are generally unsuitable for particles smaller than 50 micrometers (µm), and accuracy can begin to decrease even with materials finer than 100 mesh (approximately 150 µm). At this scale, forces like static electricity and cohesion can cause particles to clump together and clog the sieve mesh.

The Spherical Particle Assumption

Sieve analysis measures a particle's ability to pass through a two-dimensional opening. The method inherently assumes all particles are perfect spheres. This is a significant limitation when analyzing elongated or flat particles, which may pass through a mesh sideways despite having a much larger total mass or volume. This can lead to an inaccurate representation of the true particle size distribution.

Risk of Sample Alteration (Attrition)

The vigorous mechanical action of a sieve shaker can break down brittle or friable materials. This process, known as attrition, creates finer particles during the analysis itself, skewing the results to show a smaller average particle size than the original sample actually possessed.

The Challenge of Clogging and Maintenance

For the results to be accurate, the sieves must be in perfect condition. Over time, mesh openings can become clogged with near-size particles or distorted from improper handling. Regular inspection and cleaning are critical to prevent these issues from compromising the accuracy of your results.

Making the Right Choice for Your Analysis

Choosing a sieve shaker means aligning its capabilities with your specific analytical goals. Consider the nature of your material and the precision you require.

- If your primary focus is routine quality control for granular materials (>150 µm): A sieve shaker is an ideal, cost-effective, and highly reliable tool for ensuring batch-to-batch consistency.

- If your primary focus is analyzing fine powders or mixed-shape particles (50-150 µm): Use a sieve shaker for a baseline measurement, but be aware of its limitations and consider validating results with other methods if high precision is required.

- If your primary focus is analyzing nanoparticles or materials smaller than 50 µm: A sieve shaker is unsuitable; you must explore alternative methods like laser diffraction or dynamic light scattering.

Ultimately, understanding a sieve shaker's strengths and limitations is the key to leveraging it as a powerful tool for material characterization.

Summary Table:

| Merit | Description |

|---|---|

| Automation | Replaces manual sieving with consistent, machine-driven agitation. |

| Repeatability | Standardized motion ensures highly reproducible results for QC. |

| Cost-Effectiveness | Provides a simple, affordable method for particle size analysis. |

| Versatility | Suitable for both dry and wet sieving of various materials. |

| Durability | Often made from corrosion-resistant stainless steel for lab use. |

Ready to enhance your lab's particle analysis with reliable, cost-effective solutions?

KINTEK specializes in high-quality lab equipment, including durable sieve shakers designed for accurate and repeatable particle size analysis. Whether your focus is routine quality control for granular materials or you need versatile equipment for various sample types, we have the right tools to meet your laboratory's needs.

Contact us today to find the perfect sieve shaker for your application and ensure consistent, trustworthy results for your material characterization.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency