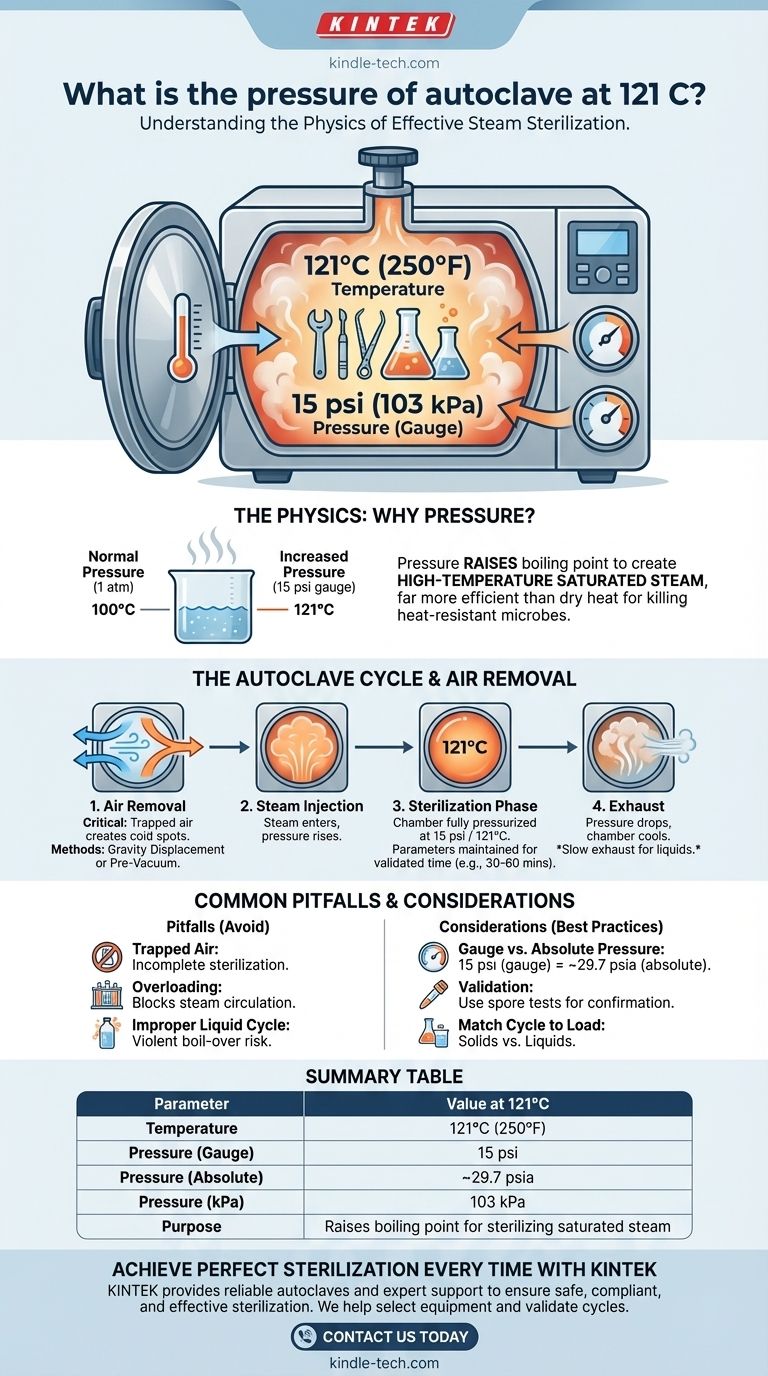

At the standard sterilization temperature of 121°C (250°F), a laboratory autoclave operates at a pressure of approximately 15 pounds per square inch (psi), which is equivalent to 103 kilopascals (kPa) or about 1.02 atmospheres above normal atmospheric pressure. This specific combination of heat and pressure is the cornerstone of effective steam sterilization.

The pressure in an autoclave is not the sterilizing agent itself. Instead, it is the necessary condition required to raise the boiling point of water to 121°C, creating high-temperature saturated steam that can rapidly destroy heat-resistant microorganisms.

The Physics of Effective Sterilization

At normal atmospheric pressure, water boils at 100°C. While hot, this temperature is not sufficient to reliably kill highly resistant bacterial spores in a practical timeframe. Autoclaving solves this by manipulating the physical properties of water.

Beyond Boiling: The Role of Saturated Steam

To achieve higher temperatures, the autoclave functions like a sophisticated pressure cooker. By increasing the pressure within its sealed chamber, it raises the boiling point of water.

The goal is to create saturated steam, which is steam at the exact temperature at which water boils at that specific pressure. This steam holds a massive amount of thermal energy that it can transfer to cooler items instantly upon contact, a process that is far more efficient for killing microbes than dry heat.

How Pressure Creates Temperature

The relationship is governed by physics. To raise the temperature of steam to 121°C, you must increase the pressure.

The target of 15 psi is specifically the gauge pressure (psig) required to make water boil at 121°C. The autoclave's control system monitors the temperature and injects or heats steam until this target is met, with the pressure naturally stabilizing as a result.

Understanding the Autoclave Cycle

A successful sterilization cycle depends on more than just hitting a pressure number on a dial. The process is a sequence of carefully controlled steps designed to ensure steam penetrates the entire load.

The Critical Importance of Air Removal

The most common cause of autoclave failure is the presence of trapped air. If pockets of air remain in the chamber or within the load, the autoclave's gauge may read 15 psi, but it will be a mixture of air and steam pressure.

Since the partial pressure of the steam is lower, the temperature in those air pockets will be below 121°C, creating cold spots where microorganisms can survive. Autoclaves use methods like gravity displacement (where steam pushes the heavier, cooler air down and out) or pre-vacuum cycles (which actively pump air out) to solve this.

Factors That Define Cycle Time

The standard cycle time of 30-60 minutes is not arbitrary. It is determined by the nature of the load.

Factors include the size, shape, and density of the items being sterilized. A large, dense pack of surgical instruments requires a longer cycle time than a few glass beakers because the steam needs more time to penetrate to the very center of the load.

Common Pitfalls and Considerations

Relying solely on the machine's readings without understanding the principles can lead to sterilization failure.

Gauge Pressure vs. Absolute Pressure

The "15 psi" figure is almost always gauge pressure (psig), meaning 15 psi above the surrounding atmospheric pressure. This is a critical distinction in physics and engineering. Absolute pressure (psia) would be approximately 29.7 psi (15 psi + 14.7 psi for atmospheric pressure at sea level).

The Risk of Improper Loading

Overloading the autoclave or wrapping items too tightly are common mistakes. These practices block steam circulation and create air pockets, preventing steam from contacting all surfaces and rendering the process ineffective.

Sterilizing Liquids Requires a Different Approach

When autoclaving liquids, a separate "liquid cycle" must be used. This cycle features a much slower pressure release (exhaust) phase to prevent the superheated liquids from boiling over violently, which can cause spills, loss of volume, and potential injury.

Making the Right Choice for Your Goal

To ensure your sterilization is successful, you must match the cycle to the load and verify the outcome.

- If your primary focus is routine sterilization of solid goods: Ensure the autoclave reaches and holds 121°C and ~15 psi for the validated time, paying close attention to proper loading to avoid air pockets.

- If you are sterilizing liquids or media: Use a dedicated liquid cycle with a slow exhaust to prevent boil-over, and remember that larger volumes require significantly longer cycle times to reach the target temperature.

- If you are validating a new process or ensuring compliance: Use biological indicators (like spore tests) placed in the most challenging part of the load to confirm that the cycle parameters achieve a true microbial kill, not just meet the machine's display readings.

Understanding the relationship between steam, temperature, and pressure is the key to achieving reliable and safe sterilization every time.

Summary Table:

| Parameter | Value at 121°C |

|---|---|

| Pressure (Gauge) | 15 psi |

| Pressure (Absolute) | ~29.7 psia |

| Pressure (kPa) | 103 kPa |

| Purpose | Raises water's boiling point to create sterilizing saturated steam |

Achieve Perfect Sterilization Every Time with KINTEK

Understanding the precise relationship between temperature and pressure is critical for effective sterilization in your laboratory. KINTEK specializes in providing reliable autoclaves and expert support to ensure your processes are safe, compliant, and effective.

We offer a range of laboratory autoclaves designed to deliver consistent performance for sterilizing solids, liquids, and media. Our team can help you select the right equipment and validate your cycles to prevent common pitfalls like air pockets and boil-overs.

Contact us today to discuss your lab's sterilization needs and discover how KINTEK's equipment and expertise can enhance your workflow's safety and reliability.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What to avoid when using an autoclave? Prevent Common and Dangerous Sterilization Errors

- What are the 3 types of autoclave? Choose the Right Sterilization Method for Your Lab

- Why is temperature important in sterilization? Achieve Complete Microbial Destruction

- What is an Autoclave Site Acceptance Test (SAT)? Ensure Compliance and Precision in Your Lab

- Do you need to autoclave glassware? A Guide to Sterilization vs. Cleaning

- Why is autoclaving used in research and medical facilities? The Gold Standard for Sterilization

- What other temperatures and times can be used to autoclave? Beyond 121°C for 15 Minutes

- How often do we need to perform maintenance on the autoclave machine? A Guide to High-Risk vs. General Use