The standard operating pressure for most autoclaves is approximately 15 pounds per square inch (psi) above atmospheric pressure. This specific pressure is not the end goal, but rather the necessary condition to raise the temperature of saturated steam to 121°C (250°F), which is the benchmark for effective sterilization.

The core principle to understand is that pressure itself does not sterilize. Instead, an autoclave uses elevated pressure as a tool to increase the temperature of steam well beyond its normal boiling point, enabling it to destroy even the most heat-resistant microorganisms.

The Core Principle: Why Pressure is Essential

An autoclave is essentially a highly controlled pressure cooker. Its effectiveness hinges on a fundamental law of physics: the boiling point of water increases as pressure increases.

Raising the Boiling Point of Water

At normal sea-level atmospheric pressure, water boils at 100°C (212°F). This temperature is sufficient for sanitation but not for true sterilization, as it cannot reliably kill hardy bacterial spores.

By increasing the pressure inside the chamber to 15 psi above atmospheric pressure, the autoclave forces water to remain in its liquid state until it reaches 121°C (250°F). At this point, it turns into high-temperature, saturated steam.

The Role of Saturated Steam

The true sterilizing agent is saturated steam. This is not just hot air; it is water vapor that carries immense thermal energy. When this steam comes into contact with cooler items in the load, it rapidly condenses back into water, transferring its heat with extreme efficiency.

This massive and rapid heat transfer is what denatures the essential proteins and enzymes within microorganisms, leading to their death.

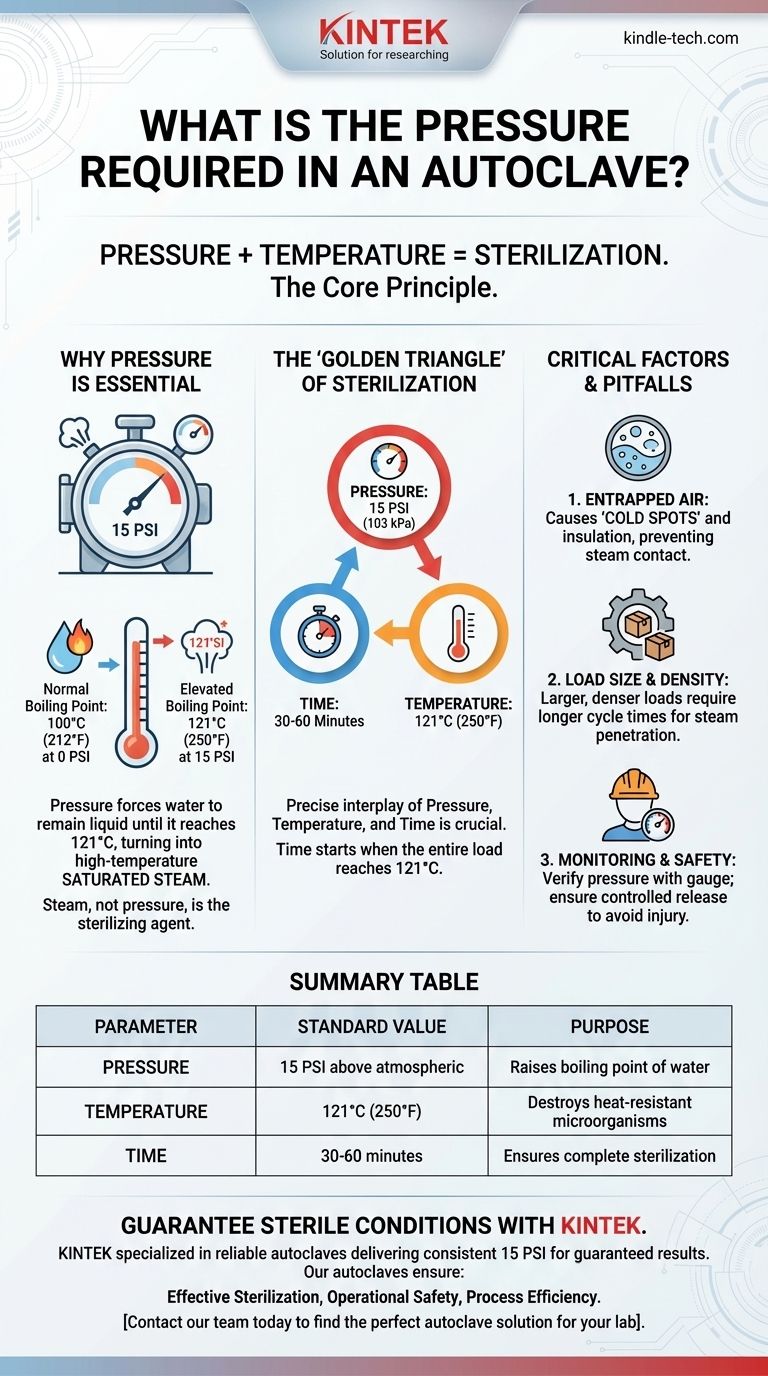

The "Golden Triangle" of Sterilization

Effective sterilization depends on the precise interplay of three factors: pressure, temperature, and time. Changing one requires adjusting the others.

Standard Parameters

The most common and widely validated cycle for general-purpose sterilization is:

- Pressure: 15 psi (103 kPa)

- Temperature: 121°C (250°F)

- Time: 30 to 60 minutes

The time is not measured from when you start the machine, but from the moment the entire load has reached the target temperature of 121°C.

Why 121°C?

This temperature is the established industry and medical standard because it is proven to be high enough to kill the most resilient forms of microbial life, particularly bacterial spores like Geobacillus stearothermophilus, which are used as biological indicators to validate autoclave performance.

Understanding the Critical Factors and Pitfalls

Achieving the correct pressure is only part of the process. Several factors can lead to a failed sterilization cycle even if the gauge reads 15 psi.

The Danger of Entrapped Air

This is the single most common cause of sterilization failure. If air is trapped within the chamber or inside the items being sterilized, it creates "cold spots."

Air acts as an insulator, preventing steam from making direct contact with surfaces. Since the sterilizing power comes from the condensation of steam, any surface insulated by an air pocket will not reach the required temperature and will not be sterilized. Modern autoclaves have vacuum cycles to remove this air before the steam is injected.

Load Size and Density

A larger or denser load requires a longer cycle time. It takes more time for steam to penetrate the center of a dense pack of surgical instruments or a large flask of liquid. The 30-60 minute cycle time is a general guideline that must be adjusted based on the contents.

Monitoring and Safety

The pressure gauge is a critical safety and monitoring tool. It allows the operator to visually confirm that the machine is reaching and maintaining the target pressure. A proper cycle also includes a controlled, slow release of pressure to prevent boiling over of liquids or damage to equipment.

Making the Right Choice for Your Goal

Understanding the principles behind the pressure setting allows you to ensure your sterilization cycles are both safe and effective.

- If your primary focus is guaranteed sterility: Ensure all air is removed from the chamber and your load is packed loosely to allow for complete steam penetration. Always use a biological indicator to validate your cycle.

- If your primary focus is operational safety: Always monitor the pressure gauge during the cycle and follow the manufacturer's specific procedures for releasing pressure to avoid injury or damage.

- If your primary focus is cycle efficiency: Adjust the sterilization time based on the size and density of the load, recognizing that a small, simple load requires less time at temperature than a large, complex one.

By mastering the relationship between pressure, temperature, and steam, you move from simply operating a machine to guaranteeing a sterile outcome.

Summary Table:

| Parameter | Standard Value | Purpose |

|---|---|---|

| Pressure | 15 PSI above atmospheric | Raises boiling point of water |

| Temperature | 121°C (250°F) | Destroys heat-resistant microorganisms |

| Time | 30-60 minutes | Ensures complete sterilization |

Guarantee Sterile Conditions in Your Lab with KINTEK

Understanding the precise relationship between pressure and temperature is critical for effective sterilization. KINTEK specializes in high-performance lab equipment, including reliable autoclaves designed to deliver consistent 15 PSI pressure for guaranteed results.

Our autoclaves ensure:

- Effective Sterilization: Precise pressure control for optimal steam temperature.

- Operational Safety: Built-in safety features and clear monitoring tools.

- Process Efficiency: Designed for various load sizes and cycle customization.

Let KINTEK's expertise support your laboratory's sterilization needs. Contact our team today to find the perfect autoclave solution for your lab.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

People Also Ask

- How does an industrial autoclave work? Unlock the Power of High-Pressure Steam for Sterilization

- What is the minimum temperature and time for autoclave? Achieve Guaranteed Sterilization Every Time

- Why must a Teflon-lined high-pressure autoclave be used for TiO2 bamboo deposition? Ensure Purity and Safety.

- What is the primary purpose of an autoclave in the preparation of media for the biological leaching of uranium?

- What role do laboratory autoclaves play in evaluating nuclear stainless steel? Ensure Safety with Realistic Simulation

- What is the primary application of a laboratory autoclave in the rice husk biorefining process? Ensure Process Purity

- What is the specific function of an autoclave with a PTFE liner? Enhance Biomass Carbonization Efficiency

- What are the advantages and disadvantages of sterilization with an autoclave? Achieve Reliable Sterilization for Your Lab