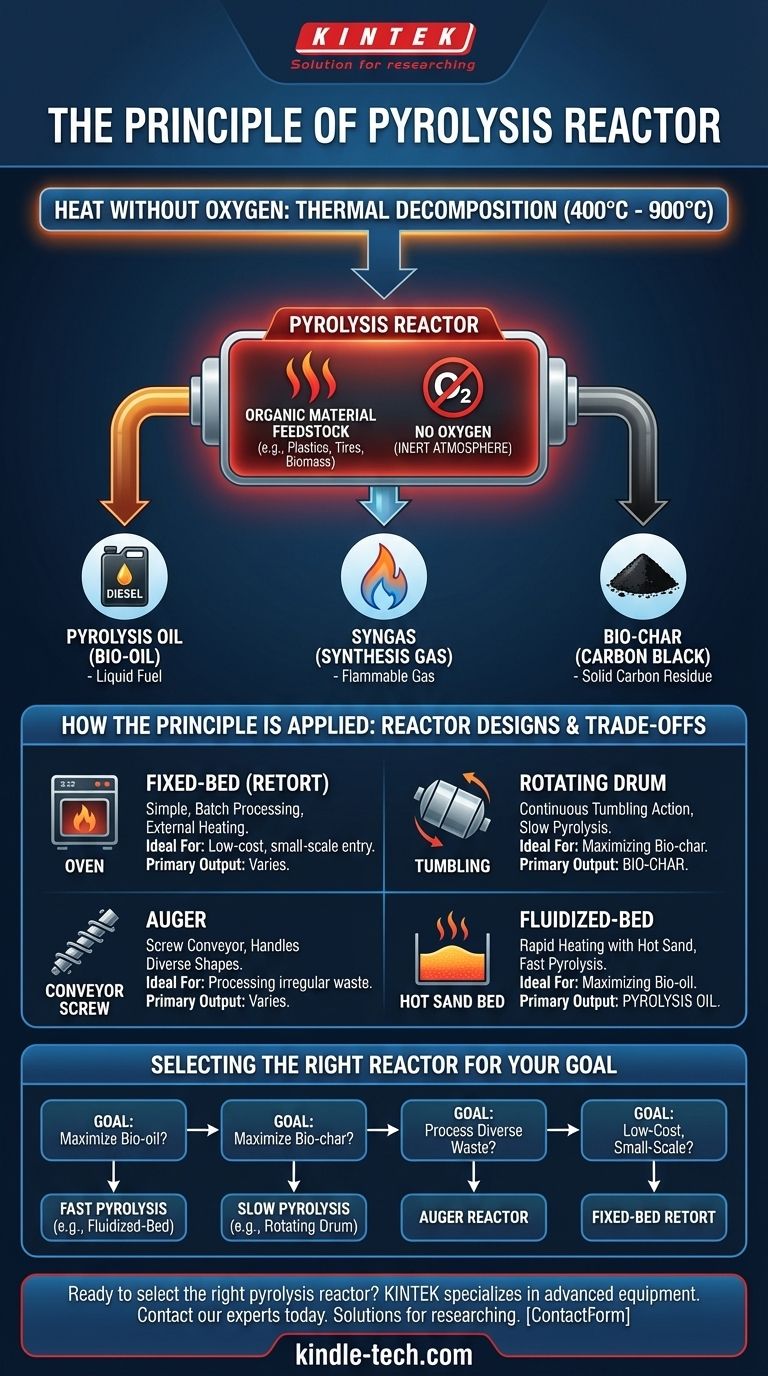

At its core, a pyrolysis reactor operates on a single, powerful principle: it uses intense heat in an oxygen-free environment to chemically decompose organic materials. Instead of burning the material through combustion, this process, known as thermal decomposition, breaks down large, complex molecules into smaller, more valuable components like liquid fuel, combustible gas, and a solid carbon-rich residue.

The fundamental principle of pyrolysis is straightforward—heat without oxygen. However, the true effectiveness of the process and the specific products it yields are determined entirely by the reactor's design, which governs how heat is transferred and the material is processed.

The Fundamental Process: Heat Without Fire

Pyrolysis is often confused with incineration, but they are fundamentally different. Incineration uses oxygen to burn waste, releasing energy and creating ash. Pyrolysis purposefully starves the process of oxygen to deconstruct materials instead.

The Critical Role of an Inert Atmosphere

The defining condition of pyrolysis is the absence of oxygen. By replacing air with an inert gas like nitrogen or simply operating in an airtight vessel, the reactor prevents combustion from occurring.

Without oxygen, the material cannot "burn" in the traditional sense. Instead, the applied heat energy breaks the chemical bonds within the feedstock's molecules.

Thermal Decomposition in Action

Inside the reactor, the feedstock (such as plastic, tires, or biomass) is heated to temperatures between 400°C and 900°C (750°F to 1650°F).

This extreme heat, combined with the lack of oxygen, causes long polymer chains to crack and break apart into smaller, more stable molecules. The process is similar to the thermal cracking used in petroleum refining but is applied to waste streams instead of crude oil.

The Three Primary Outputs

The decomposition process reliably yields three distinct products, each with its own value:

- Pyrolysis Oil (Bio-oil): A liquid fuel comparable to a low-grade diesel, which can be refined for higher quality or used directly in certain engines and boilers.

- Syngas (Synthesis Gas): A mixture of flammable gases (primarily hydrogen and carbon monoxide) that can be captured and burned to power the pyrolysis reactor itself, making the process more energy-efficient.

- Bio-char (Carbon Black): A solid, carbon-rich material. When derived from biomass, it can be used as a soil amendment. When derived from tires or plastics, it serves as a raw material known as carbon black.

Reactor Designs: How the Principle is Applied

While the core principle remains constant, different reactor designs apply it in unique ways. The design choice dictates the speed of the process and the proportion of liquid, gas, and solid outputs.

Fixed-Bed Reactors (The "Oven" Approach)

Also known as a retort reactor, this is the simplest design. It is essentially an airtight vessel heated from an external source, much like an oven.

Heat transfers slowly through the vessel's walls into the static batch of feedstock. This method is straightforward but can result in uneven heating and is generally less efficient than more dynamic systems.

Rotating Drum Reactors (The "Tumbling" Approach)

This design features a large, cylindrical drum that rotates slowly while being heated externally.

The rotation continuously tumbles the feedstock, ensuring more uniform exposure to heat. This method is typically used for slow pyrolysis, which maximizes the production of bio-char.

Auger Reactors (The "Conveyor" Approach)

An auger reactor uses a large, motor-driven screw to simultaneously mix and transport feedstock through a heated chamber.

This design offers excellent control over how long the material stays in the reactor. It relies on mechanical force and pressure for heat transfer and is very effective at handling a wide variety of feedstock shapes and sizes.

Fluidized-Bed Reactors (The "Hot Sand" Approach)

This highly efficient design uses a bed of inert material, like sand, at the bottom of the reactor. An inert gas (like nitrogen) is pumped up through the sand, causing it to behave like a fluid.

This "fluidized" hot sand engulfs the feedstock particles, enabling extremely rapid and uniform heat transfer. This method is ideal for fast pyrolysis, which maximizes the yield of pyrolysis oil.

Understanding the Trade-offs

Choosing a pyrolysis technology is not about finding the "best" reactor, but the right one for a specific goal. Each design involves clear trade-offs.

Speed vs. Product Yield

The rate of heating directly impacts the final products.

- Fast Pyrolysis (e.g., Fluidized-Bed): Seconds of processing time. Favors the production of liquids (pyrolysis oil).

- Slow Pyrolysis (e.g., Rotating Drum): Hours of processing time. Favors the production of solids (bio-char).

Feedstock Requirements

The physical nature of the waste material matters. Fluidized-bed reactors require small, uniform particles for optimal performance. In contrast, auger and rotating drum reactors are more robust and can handle less-prepared, more varied feedstocks.

Complexity and Cost

Simpler designs like fixed-bed retorts have lower initial capital costs but suffer from lower efficiency and less precise process control.

Advanced designs like fluidized-bed reactors are more complex and expensive to build and operate but offer superior heat transfer, higher throughput, and more consistent product quality.

Making the Right Choice for Your Goal

The optimal reactor design is directly tied to your desired primary output.

- If your primary focus is maximizing liquid fuel (bio-oil): A fast pyrolysis design like a fluidized-bed reactor is the most effective choice due to its rapid heat transfer.

- If your primary focus is producing solid bio-char for agriculture or carbon products: A slow pyrolysis design like a rotating drum reactor is ideal for maximizing the solid residue.

- If your primary focus is processing diverse or irregularly shaped waste: An auger reactor provides the mechanical robustness needed for reliable material handling.

- If your primary focus is low-cost, small-scale batch processing: A simple fixed-bed retort reactor offers a viable entry point into the technology.

Understanding these design principles allows you to move beyond the "what" of pyrolysis to the "how," enabling you to select the precise technology for your specific application.

Summary Table:

| Reactor Type | Key Characteristic | Ideal For | Primary Output |

|---|---|---|---|

| Fixed-Bed (Retort) | Simple, batch processing, external heating | Low-cost, small-scale entry | Varies |

| Rotating Drum | Tumbling action, slow pyrolysis | Maximizing bio-char production | Bio-char |

| Auger | Screw conveyor, handles diverse feedstocks | Processing irregular waste shapes | Varies |

| Fluidized-Bed | Rapid heating with hot sand, fast pyrolysis | Maximizing pyrolysis oil yield | Pyrolysis Oil |

Ready to select the right pyrolysis reactor for your specific waste conversion goals? The optimal design depends on your target output—whether it's maximizing bio-oil, bio-char, or handling diverse feedstocks. KINTEK specializes in advanced laboratory equipment and consumables, providing the precise reactor technology you need to efficiently transform waste materials into valuable products. Contact our experts today to discuss your project and discover how our solutions can enhance your lab's capabilities and drive your research forward.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process