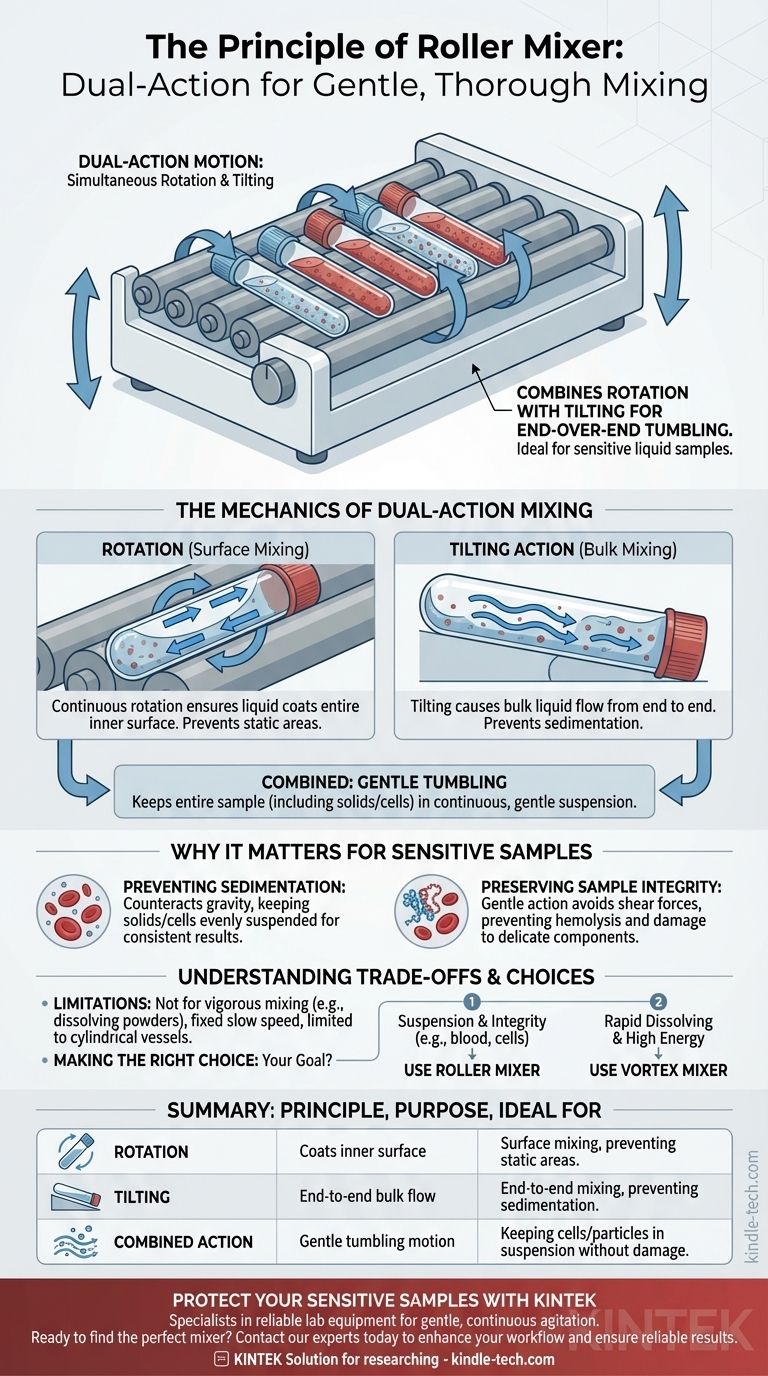

At its core, a roller mixer operates on a principle of dual-action motion. It uses a set of motor-driven rollers to continuously rotate sample tubes or bottles. Simultaneously, the entire roller assembly is gently tilted up and down, causing the liquid to flow back and forth along the length of the tube, ensuring a thorough yet gentle mix.

The crucial insight is that a roller mixer is not just for rolling. It combines rotation with a tilting action to create a gentle, end-over-end tumbling motion, making it the ideal choice for continuously mixing sensitive liquid samples without causing damage.

The Mechanics of Dual-Action Mixing

To understand why this piece of equipment is a staple in many labs, we must break down its two simultaneous movements. Each action serves a distinct but complementary purpose.

The Role of Rotation

The most visible action is the rotation. The samples, typically in cylindrical tubes or bottles, are placed between the rollers.

A motor drives these rollers at a fixed, low speed. This causes the sample vessels to spin slowly, ensuring the liquid constantly coats the entire inner surface of the container.

The Tilting Action

The second, less obvious action is the tilting or "rocking." One end of the roller apparatus is gently raised and then lowered by a cam mechanism.

This tilting causes the entire liquid volume to flow from one end of the tube to the other. This ensures bulk movement of the fluid, preventing any part of the sample from remaining static.

Combining Rotation and Tilting

The combination of these two movements is what makes the roller mixer so effective. The rotation ensures surface mixing, while the tilting ensures bulk, end-to-end mixing.

Together, they create a gentle, wave-like, tumbling motion. This guarantees that the entire sample—including any solids or cellular components—is kept in a state of continuous, gentle suspension.

Why This Principle Matters for Sensitive Samples

The design of a roller mixer is a direct solution for specific laboratory challenges that other mixers cannot address. Its gentle nature is a feature, not a bug.

Preventing Sedimentation

For samples containing particles, cells, or beads, gravity will cause them to settle at the bottom of the tube over time, a process called sedimentation.

The continuous, gentle motion of a roller mixer effectively counteracts gravity, keeping solids evenly suspended throughout the liquid for extended periods. This is critical for consistent results in hematology and other assays.

Preserving Sample Integrity

Vigorous mixing methods, like a vortexer, create high shear forces that can damage or destroy fragile components.

A roller mixer is designed to avoid this. Its gentle action is ideal for whole blood samples (preventing hemolysis, or the rupture of red blood cells), fragile protein solutions, and delicate cell cultures.

Understanding the Trade-offs

While highly effective for its intended purpose, the roller mixer is not a universal solution. Understanding its limitations is key to using it correctly.

Not for Vigorous Mixing

The gentle action is a disadvantage when you need to mix something quickly or forcefully. It is not the right tool for rapidly dissolving a solid powder or creating a high-energy emulsion. A vortex mixer or magnetic stirrer is far better suited for those tasks.

Speed is Fixed and Slow

Most roller mixers operate at a single, low speed. They are deliberately designed this way to protect samples. They lack the variable speed control needed for applications that require fine-tuning the agitation intensity.

Limited to Cylindrical Vessels

The design is specifically for tubes and bottles that can roll. It is not compatible with other common labware like Erlenmeyer flasks, beakers, or microplates.

Making the Right Choice for Your Goal

Selecting the correct mixer depends entirely on the nature of your sample and your desired outcome.

- If your primary focus is keeping cells or particles in suspension: The gentle, continuous agitation of a roller mixer is the ideal method for preventing sedimentation without damaging the sample.

- If your primary focus is mixing blood samples for analysis: A roller mixer is the industry standard, as it guarantees a homogeneous sample while preventing the cell damage that would invalidate test results.

- If your primary focus is rapidly dissolving a powder or mixing two low-viscosity liquids: You should use a vortex mixer for its speed and high-energy agitation.

By understanding the principle of combined rolling and tilting, you can confidently choose the right tool to protect your sample's integrity and ensure reliable results.

Summary Table:

| Principle | Purpose | Ideal For |

|---|---|---|

| Rotation | Ensures liquid coats the entire inner surface of the tube. | Surface mixing, preventing static areas. |

| Tilting | Causes bulk liquid to flow from one end of the tube to the other. | End-to-end mixing, preventing sedimentation. |

| Combined Action | Creates a gentle, wave-like tumbling motion. | Keeping cells/particles in suspension without damage. |

Protect the integrity of your sensitive samples with the right mixing equipment.

KINTEK specializes in providing reliable laboratory equipment, including roller mixers designed for gentle, continuous agitation. Whether you are working with whole blood, fragile cell cultures, or protein solutions, our solutions help you achieve homogeneous mixing without compromising sample integrity.

Ready to find the perfect mixer for your lab's needs? Contact our experts today to discuss how KINTEK's lab equipment can enhance your workflow and ensure reliable results.

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory Single Horizontal Jar Mill

People Also Ask

- Why is a rotary ball mill with grinding media required for mixing Inconel 625 with carbide powders?

- What role does a horizontal ball mill play in YAG ceramic mixing? Achieve Superior Microscopic Uniformity

- Why are agate grinding jars preferred for Li2S-P2S5 electrolytes? Ensure Purity in Solid-State Battery Research

- What is the function of grinding jars with transparent windows? Unlock Real-Time In-Situ Mechanochemistry Insights

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- What is the primary function of agate grinding jars and balls in Li4Ti5O12 prep? Ensure Purity & Performance

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- What is the primary role of a drum ball mill in copper-based composite preparation? Achieve Homogeneous Cu-SiC Mixtures