In essence, a wiped film molecular still is a purification technology designed to separate compounds at significantly lower temperatures than their normal boiling points. It achieves this by spreading a liquid into an ultra-thin film on a heated surface inside a high-vacuum chamber, allowing volatile molecules to evaporate and travel a short, unobstructed path to an internal condenser for collection.

The core principle is not just separation, but preservation. Wiped film molecular distillation is engineered to purify thermally sensitive, high-boiling-point compounds that would be damaged or destroyed by traditional distillation methods.

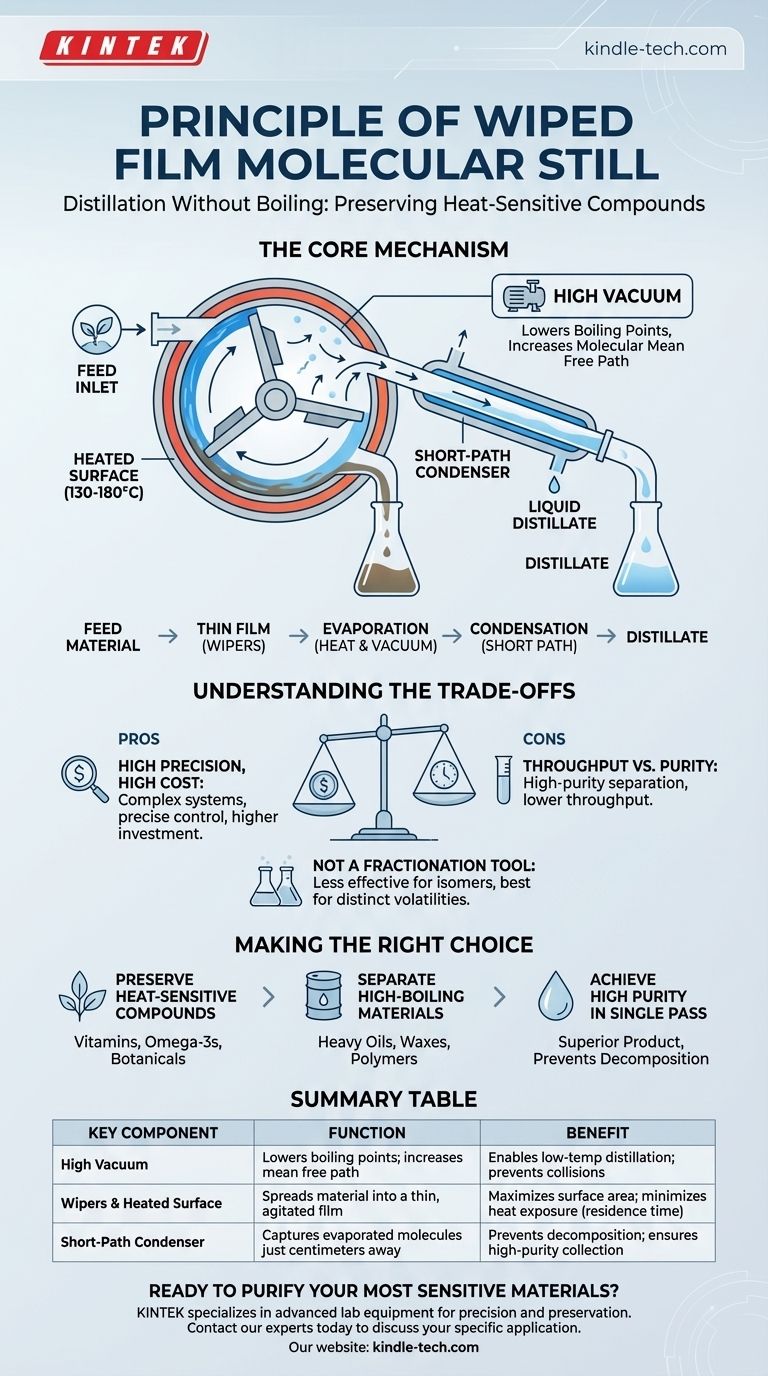

The Core Mechanism: Distillation Without Boiling

The genius of this technique lies in its ability to manipulate physical conditions—pressure, temperature, and time—to achieve precise separation. This is accomplished through a synergy of three key components.

The Role of High Vacuum

The entire process occurs under a deep vacuum. This drastically lowers the temperature required for a substance to evaporate.

Critically, the high vacuum increases the mean free path of molecules—the average distance a molecule can travel before colliding with another. In a molecular still, this path is engineered to be longer than the distance to the condenser, ensuring an unobstructed journey.

The Heated Surface and Wipers

The feed material is introduced onto the inner wall of a vertical, jacketed cylinder that is heated, often by a circulating oil unit. The distillation temperature is typically between 130-180°C (266-356°F), though the system can reach much higher.

Rotating wipers then continuously smear this material into an extremely thin, agitated film. This action has two profound effects: it maximizes the surface area for rapid evaporation and drastically reduces the residence time, minimizing the material's exposure to heat.

The "Short Path" Condenser

Unlike traditional distillation where vapors travel up a column, a molecular still features an internal condenser placed just centimeters away from the heated wall.

Evaporated molecules travel this short distance and are immediately captured as a liquid distillate. The less volatile, heavier residue that did not evaporate continues down the heated wall and is collected separately at the bottom.

Understanding the Trade-offs

While powerful, this technology is a specialized tool with specific limitations. Understanding them is key to its proper application.

High Precision, High Cost

Wiped film systems are complex instruments. They require precise control over vacuum levels, feed rate, and multiple temperature zones. This sophistication results in higher capital and operational costs compared to simpler distillation setups.

Throughput vs. Purity

These systems are designed for high-purity separation of difficult materials, not high-volume stripping of simple solvents. While they operate continuously, their throughput may be lower than a large-scale traditional still designed for less demanding separations.

Not a Fractionation Tool

Molecular distillation excels at separating materials with significantly different volatilities (e.g., separating a volatile active ingredient from heavy waxes). It is less effective for separating compounds with very similar boiling points (isomers), which would require fractional distillation.

Making the Right Choice for Your Goal

This method is chosen when the value and sensitivity of the material justify the process.

- If your primary focus is preserving heat-sensitive compounds: This is the ideal method for purifying vitamins, omega-3 fatty acids, or botanical extracts without thermal degradation.

- If your primary focus is separating high-boiling-point materials: This technology makes it possible to distill heavy oils, waxes, and polymers that are impossible to process with conventional equipment.

- If your primary focus is achieving high purity in a single pass: The short-path design prevents decomposition and cross-contamination, often yielding a superior product compared to multi-stage alternatives.

By precisely controlling heat, time, and pressure, wiped film molecular distillation provides a powerful solution for purifying materials that other methods would destroy.

Summary Table:

| Key Component | Function | Benefit |

|---|---|---|

| High Vacuum | Lowers boiling points; increases molecular mean free path. | Enables low-temperature distillation; prevents molecular collisions. |

| Wipers & Heated Surface | Spreads material into a thin, agitated film. | Maximizes surface area; minimizes heat exposure time (residence time). |

| Short-Path Condenser | Captures evaporated molecules just centimeters away. | Prevents decomposition; ensures high-purity collection. |

Ready to Purify Your Most Sensitive Materials?

KINTEK specializes in advanced lab equipment, including wiped film molecular stills designed for precision and preservation. Our systems are ideal for laboratories processing heat-sensitive compounds like botanical extracts, vitamins, and high-boiling-point oils.

Let us help you achieve superior purity without compromising your product's integrity.

Contact our experts today to discuss your specific application and find the perfect solution for your lab's needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings