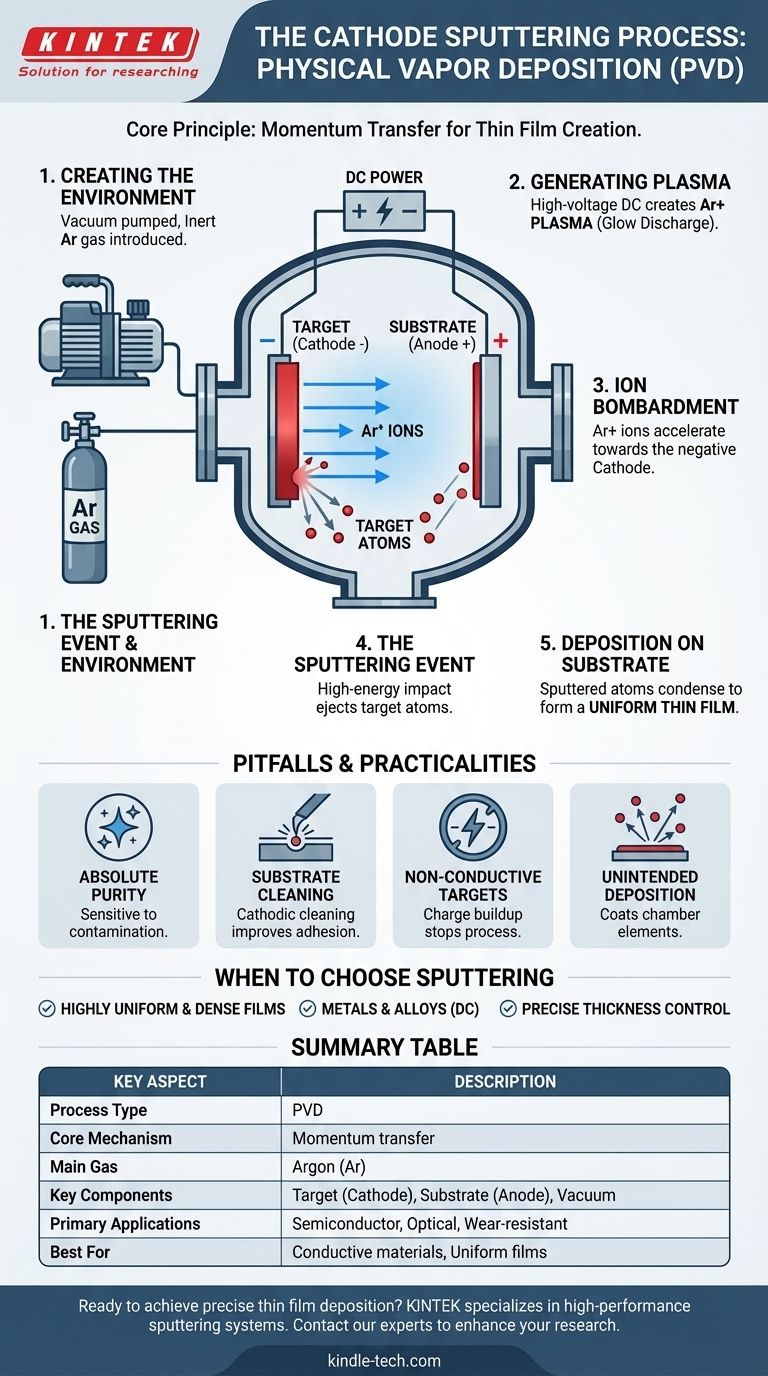

At its core, cathode sputtering is a physical vapor deposition (PVD) technique used to create ultra-thin films. The process uses high-energy ions to bombard a source material, known as the target, physically dislodging atoms from its surface. These ejected atoms then travel through a vacuum and condense onto a separate surface, the substrate, building up a uniform coating atom by atom.

The central principle of cathode sputtering is momentum transfer. By creating a plasma and using an electric field to accelerate ions into a target, the process effectively "sandblasts" the target material on an atomic scale, resulting in a controlled and highly uniform deposition of that material elsewhere.

The Core Mechanism: From Plasma to Film

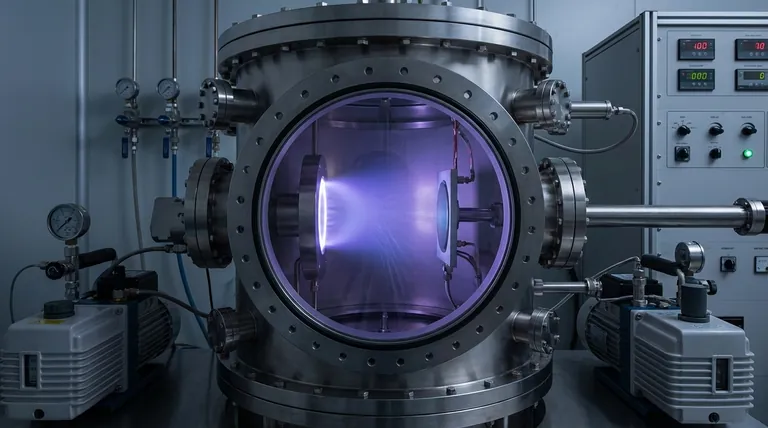

The entire sputtering process takes place within a sealed vacuum chamber. Understanding it involves a clear, five-step sequence that transforms a solid material into a precise thin film.

Step 1: Creating the Environment

Before the process begins, the chamber is pumped down to a very low pressure, creating a vacuum. This is critical to remove air and other contaminants. An inert gas, most commonly Argon (Ar), is then introduced into the chamber at a controlled low pressure.

Step 2: Generating the Plasma

A high-voltage DC electric field is applied between two electrodes: the target material, which acts as the cathode (negative electrode), and the substrate, which acts as the anode (positive electrode). This strong electric field strips electrons from some of the Argon atoms, creating a mix of free electrons and positively charged Argon ions (Ar+). This energized, ionized gas is known as a plasma or "glow discharge."

Step 3: The Ion Bombardment

The positively charged Argon ions (Ar+) are strongly attracted and accelerated towards the negatively charged target (the cathode). They gain significant kinetic energy as they travel across the electric field.

Step 4: The Sputtering Event

Upon impact, the high-energy ions slam into the surface of the target. This collision sets off a "collision cascade," transferring momentum to the atoms within the target material. If the energy transferred to a surface atom is greater than the energy that binds it to the target, that atom is ejected or "sputtered" away.

Step 5: Deposition on the Substrate

The sputtered atoms from the target travel through the low-pressure chamber. They eventually reach the substrate, where they condense on the surface. Over time, this atomic deposition builds up to form a dense, uniform, and high-purity thin film.

Understanding the Pitfalls and Practicalities

While the principle is straightforward, successful sputtering depends on careful control of the process environment and an awareness of its limitations.

The Need for Absolute Purity

The quality of the final film is highly sensitive to contamination. The sputtering gas must be clean and dry to maintain the desired composition of the coating. Likewise, the substrate itself must be pristine to ensure the deposited film adheres properly.

Substrate Cleaning

To improve film adhesion, a technique called cathodic cleaning is often used. Before deposition begins, the voltage polarity is temporarily reversed. This turns the substrate into the cathode, causing it to be bombarded by ions that etch away any surface contaminants.

The Challenge of Non-Conductive Targets

The simple DC sputtering process described here works exceptionally well for conductive materials like metals. However, when sputtering insulating (non-conductive) materials, positive ions accumulate on the target's surface. This charge buildup eventually repels the incoming Argon ions, stopping the sputtering process.

Unintended Deposition

The sputtered material travels in many directions. While most of it coats the substrate, some can end up on other elements within the vacuum chamber. This can alter the chamber's electrical properties over time or even cause short circuits.

When to Choose Cathode Sputtering

Deciding if sputtering is the right method depends on the specific goals of your application.

- If your primary focus is creating highly uniform and dense films: Sputtering excels at depositing thin layers with excellent coverage and strong adhesion across the entire substrate.

- If your primary focus is working with metals and alloys: DC cathode sputtering is a reliable, repeatable, and well-established process for depositing conductive materials.

- If your primary focus is precise control over film thickness: The process offers a very stable and controllable deposition rate, allowing for the creation of films with exact thicknesses down to the atomic level.

Ultimately, cathode sputtering is a foundational technology in modern manufacturing, enabling the production of everything from semiconductor devices to optical coatings and hard-wearing surfaces.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Momentum transfer via ion bombardment |

| Main Gas Used | Argon (Ar) |

| Key Components | Target (cathode), Substrate (anode), Vacuum chamber |

| Primary Applications | Semiconductor devices, optical coatings, wear-resistant surfaces |

| Best For | Conductive materials, highly uniform and dense films |

Ready to achieve precise thin film deposition in your lab? KINTEK specializes in high-performance sputtering systems and lab equipment designed for researchers and manufacturers who demand superior film quality, uniformity, and process control. Whether you're working with metals, alloys, or advanced materials, our solutions deliver the reliability and precision your laboratory needs. Contact our experts today to discuss how our sputtering technology can enhance your research and production capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the difference between CVD and ALD? Choosing the Right Thin Film Deposition Method

- What machines make lab diamonds? Discover the HPHT and CVD Technologies Behind Lab-Grown Gems

- Which gases are used in CVD process? A Guide to Precursors and Carrier Gases

- What is atomic layer deposition of a gas? Achieve Perfectly Uniform Thin Films with Atomic Precision

- How do they make diamonds in CVD? Unlock the Secrets of Lab-Grown Diamond Creation

- What is sputtering atmosphere? The Key to Controlled Thin Film Deposition

- Why do we use CVD? Unlock Unmatched Precision in Thin Film Deposition

- What role do high-temperature CVD furnaces play in synthesizing CNT arrays for de-icing? Precision Aerospace Engineering