In essence, a hammer mill is a machine designed for impact-based size reduction. Its primary purpose is to take larger, often brittle materials and shatter them into smaller, more uniform particles. This is achieved not through cutting or abrasion, but through the brute force of high-speed rotating hammers striking the material repeatedly.

A hammer mill operates on a simple yet powerful principle: material is pulverized by rapid, repeated impacts rather than being cut or ground. This makes it a versatile and high-throughput tool for breaking down a wide range of materials, from grain to rock.

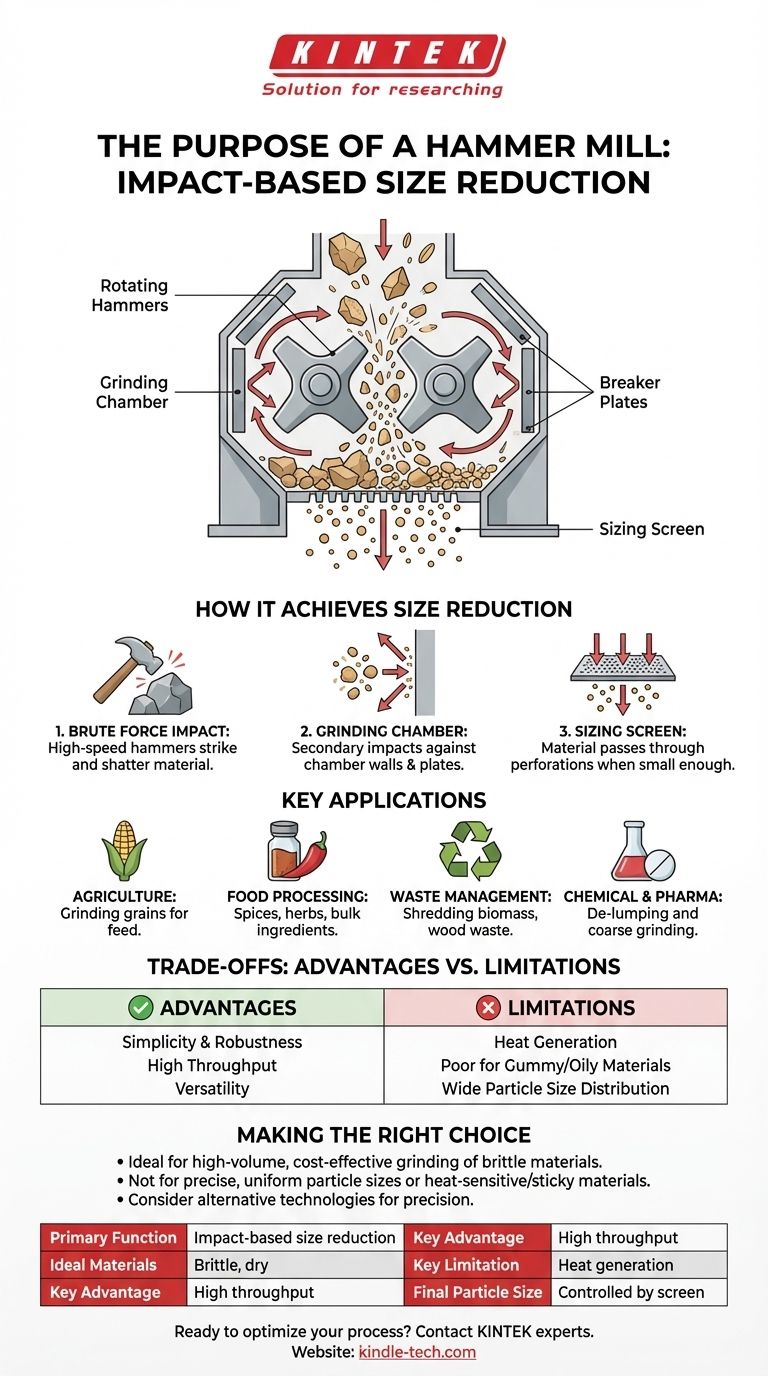

How a Hammer Mill Achieves Size Reduction

The effectiveness of a hammer mill lies in its straightforward mechanical design, which is optimized for high-energy collisions.

The Principle of Brute Force Impact

A hammer mill contains a rotor that spins at a very high velocity inside a grinding chamber. This rotor is fitted with numerous swinging hammers.

When material is fed into the mill, it is not cut. Instead, it is struck by the hammers, instantly shattering it upon impact.

The Grinding Chamber

The material, now broken into smaller pieces, is thrown against the inner walls of the grinding chamber, often lined with breaker plates. This secondary impact causes further size reduction.

This cycle of being struck by hammers and colliding with the chamber walls repeats hundreds or thousands of times per second.

The Sizing Screen

The bottom of the chamber is lined with a perforated screen or grate. The shattered material remains in the chamber, continuously impacted, until it is small enough to pass through the holes in this screen.

The size of the holes in the screen is what ultimately determines the maximum particle size of the final product.

Key Applications of a Hammer Mill

While commonly associated with agriculture, the hammer mill's utility extends to many industrial processes.

Agricultural Feed Production

This is the classic application. Hammer mills are used to grind grains like corn, wheat, and barley, as well as forage and other roughage, into a consistent meal for animal feed.

Food and Spice Processing

Many bulk food ingredients, such as sugar, spices, and dried herbs, are milled to a desired powder consistency using hammer mills. The high throughput is ideal for large-scale production.

Waste Management and Biomass

Hammer mills excel at processing brittle waste materials. They are used to shred wood waste, pallets, and agricultural biomass into smaller particles for conversion into fuel pellets or for composting.

Pharmaceutical and Chemical Milling

In these industries, hammer mills are used for "de-lumping" agglomerated powders or for coarse grinding of raw materials before a finer milling process.

Understanding the Trade-offs

No single technology is perfect for every task. The hammer mill's strengths are balanced by specific limitations.

Advantage: Simplicity and Robustness

The mechanical design is simple, with few complex parts. This makes hammer mills durable, reliable, and relatively easy to maintain compared to more sophisticated grinders.

Advantage: High Throughput and Versatility

They can process a large volume of material quickly and can handle a wide variety of brittle or fibrous inputs without requiring significant reconfiguration.

Limitation: Heat Generation

The high-speed impacts generate considerable heat. This can be detrimental when processing heat-sensitive materials, potentially causing degradation, melting, or altering the chemical properties of the product.

Limitation: Poor for Gummy or Oily Materials

Materials with high moisture, oil, or fat content tend to smear and clog the outlet screen. This drastically reduces efficiency and requires frequent cleaning.

Limitation: Particle Size Distribution

While the screen sets the maximum particle size, the output often includes a wide range of finer particles. If a very narrow, uniform particle size is required, a hammer mill may not be the best choice.

Making the Right Choice for Your Goal

To determine if a hammer mill is the appropriate tool, you must first define your material and your desired output.

- If your primary focus is high-volume, cost-effective grinding of brittle materials: A hammer mill is an excellent and often default choice for applications like animal feed or biomass processing.

- If your primary focus is achieving a very precise and uniform particle size: You should investigate alternative technologies like a roller mill or a pin mill that offer more control over the output.

- If your primary focus is processing heat-sensitive or sticky materials: A low-speed grinder or a system employing cryogenic cooling would be necessary to prevent product degradation and screen clogging.

Understanding that the hammer mill is an instrument of impact, not precision, is the key to deploying it effectively in your process.

Summary Table:

| Feature | Description |

|---|---|

| Primary Function | Impact-based size reduction (crushing/shattering) |

| Ideal Materials | Brittle, dry materials (grains, spices, wood, chemicals) |

| Key Advantage | High throughput, versatility, and simple, robust design |

| Key Limitation | Generates heat; not ideal for heat-sensitive, oily, or gummy materials |

| Final Particle Size | Controlled by a sizing screen at the mill's outlet |

Ready to optimize your size reduction process?

Whether you're processing agricultural feed, biomass, or chemicals, selecting the right equipment is critical for efficiency and product quality. KINTEK specializes in providing robust and reliable lab equipment, including hammer mills, to meet your specific grinding needs.

Our experts can help you determine if a hammer mill is the right solution for your material and desired output. Contact us today to discuss your application and get a personalized recommendation.

Visual Guide

Related Products

- Powerful Plastic Crusher Machine

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Jaw Crusher

- Three-dimensional electromagnetic sieving instrument

- Sealed Jaw Crusher High Efficiency Environmental Protection Safe and Reliable

People Also Ask

- What is the particle size of a ball mill? Control Your Grind from Microns to Nanometers

- What is the primary function of a ball mill in magnesium production? Optimize Pretreatment for Efficiency

- What are the advantages of using an agate mortar for manual mixing? Protect Particle Integrity in Solid-State Batteries

- Why is it important to grind the sample finely and pack it tightly before performing a melting point determination? Ensure Accurate and Sharp Melting Points

- How much volume should be filled in the ball mill? Optimize Grinding Efficiency & Reduce Wear

- What size are grinding balls? Optimize Your Grinding Circuit for Maximum Efficiency

- Why are high-shear mixing or ultrasonic homogenizers necessary for MMT nanocomposites? Unlock True Nano-Reinforcement

- What is the function of grinding equipment in the pre-treatment of lean coal and SCCBs? Unlock Precision Results