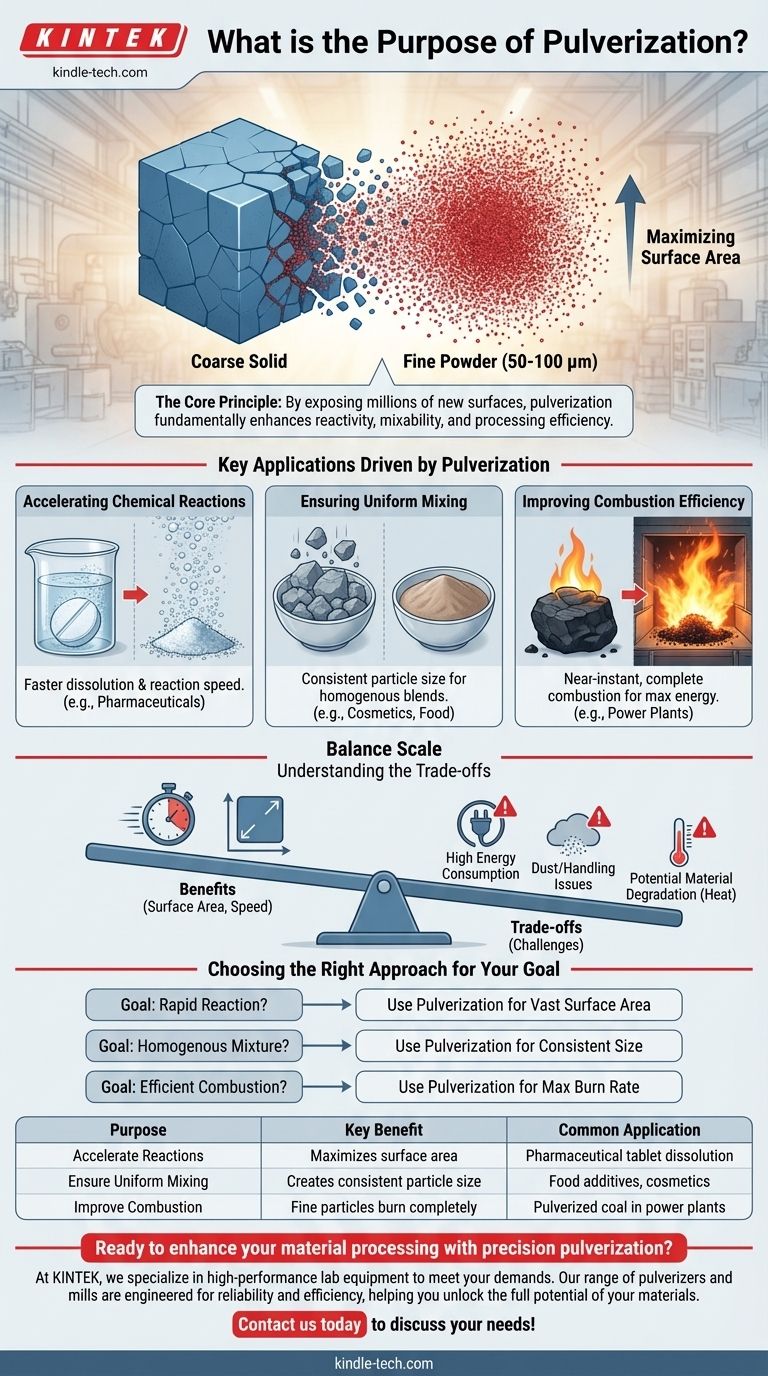

In essence, pulverization is the mechanical process of reducing a solid material into a fine powder. This operation grinds coarse pieces into much smaller particles, typically between 50 and 100 micrometers in size, to prepare them for industrial or pharmaceutical use.

The true purpose of pulverization is not merely to make something smaller. It is a strategic process designed to dramatically increase a material's total surface area, which fundamentally enhances its reactivity, mixability, and processing efficiency.

The Core Principle: Maximizing Surface Area

Pulverization is governed by a simple geometric principle. When you break a solid object into smaller pieces, you expose new surfaces, drastically increasing the total area available for physical and chemical interactions.

The Power of Exposure

Imagine a single, solid cube. It has only six faces exposed to the environment.

Now, imagine cutting that same cube into a million microscopic cubes. While the total volume remains the same, you have exposed millions of new surfaces.

Why Surface Area Matters

Nearly all important processes—such as dissolving, burning, or reacting—happen at the surface of a material. By creating a fine powder, you create an exponentially larger stage for these actions to occur, making them faster and more complete.

Key Applications Driven by Pulverization

The benefits of increased surface area are leveraged across numerous industries, from energy production to healthcare.

Accelerating Chemical Reactions

In chemistry, reaction speed is often limited by how well reactants can make contact. Powders mix intimately and dissolve almost instantly, accelerating reactions that would be sluggish with solid chunks.

This is critical in pharmaceuticals, where the speed at which a tablet dissolves can determine the drug's effectiveness.

Ensuring Uniform Mixing

Achieving a perfectly homogenous mixture is nearly impossible with coarse materials of different sizes and densities.

Pulverizing all components to a similar, fine particle size allows them to be blended uniformly. This ensures consistent quality in products like cosmetics, food additives, and concrete.

Improving Combustion Efficiency

A large lump of coal burns slowly and inefficiently from the outside in.

In contrast, pulverized coal blown into a furnace behaves almost like a flammable gas. The massive surface area allows for near-instantaneous and complete combustion, maximizing energy extraction in power plants.

Understanding the Trade-offs

While powerful, pulverization is not a universally perfect solution. It involves clear engineering and operational trade-offs that must be considered.

Significant Energy Consumption

Grinding hard materials into a fine powder is an energy-intensive process. The machinery required is heavy and consumes a substantial amount of power, which can be a primary operational cost.

Material Handling Challenges

Fine powders can be difficult to manage. They can create dust hazards (which can be explosive or a health risk), flow poorly in hoppers, and are often sensitive to moisture, which can cause clumping.

Potential for Material Degradation

The mechanical force and friction involved in pulverization generate heat. For heat-sensitive materials, such as certain polymers or complex organic compounds, this can alter or degrade their chemical properties.

Choosing the Right Approach for Your Goal

Pulverization is a tool used to achieve a specific outcome. Evaluating your primary objective is key to determining if it's the correct process.

- If your primary focus is rapid reaction or dissolution: Pulverization is essential for creating the vast surface area needed for maximum speed and efficiency.

- If your primary focus is a homogenous mixture: Reducing components to a fine powder is the most reliable method for ensuring a consistent, uniform blend.

- If your primary focus is complete and efficient combustion: Pulverizing fuel is critical for maximizing the burn rate and extracting the most energy.

Ultimately, pulverization is a transformative process that alters a material's physical form to unlock its chemical and physical potential.

Summary Table:

| Purpose | Key Benefit | Common Application |

|---|---|---|

| Accelerate Reactions | Maximizes surface area for faster chemical interactions | Pharmaceutical tablet dissolution |

| Ensure Uniform Mixing | Creates consistent particle size for homogenous blends | Food additives, cosmetics, concrete |

| Improve Combustion | Fine particles burn completely and efficiently | Pulverized coal in power plants |

Ready to enhance your material processing with precision pulverization?

At KINTEK, we specialize in high-performance lab equipment and consumables designed to meet the rigorous demands of your laboratory. Whether your goal is to accelerate reactions, ensure uniform mixing, or improve combustion efficiency, the right pulverization equipment is key to achieving consistent, high-quality results.

Our range of pulverizers and mills are engineered for reliability and efficiency, helping you unlock the full potential of your materials. Let our experts help you select the ideal solution for your specific application.

Contact us today to discuss your needs and discover how KINTEK can power your lab's success!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary purpose of using zirconia (ZrO2) grinding balls? Optimize Purity in ZrB2–SiC–TaC Milling

- What is a screw mixer? Achieve Gentle, Homogeneous Blending of Powders

- What industries use hammer mills? The Versatile Grinding Solution for Agriculture, Recycling, and More

- Can you make flour with a hammer mill? Yes, for Coarse, Whole-Grain Flour & Animal Feed

- Where are hammer mills used? From Agriculture to Recycling, a Versatile Size-Reduction Solution

- What is the function of a high-energy ball mill in the synthesis of LPS? Unlock High Ionic Conductivity Today

- How many balls are needed for a ball mill? Optimize grinding with the right charge volume.

- What is the function of a ball mill in photocatalyst preparation? Enhance Specific Surface Area and Phase Uniformity