The primary purpose of a sieve shaker is to provide a consistent and repeatable mechanical action for sieve analysis. This automated agitation ensures that particle separation is uniform and reliable, removing the significant variability and inaccuracy associated with manual shaking. By standardizing the sieving process, a shaker produces data that is trustworthy for critical quality control and engineering decisions.

A sieve shaker transforms particle size analysis from a subjective approximation into a precise, reproducible scientific method. It replaces the inherent inconsistency of manual shaking with a controlled, mechanical force, which is the key to achieving the accuracy demanded by modern quality control and material specification standards.

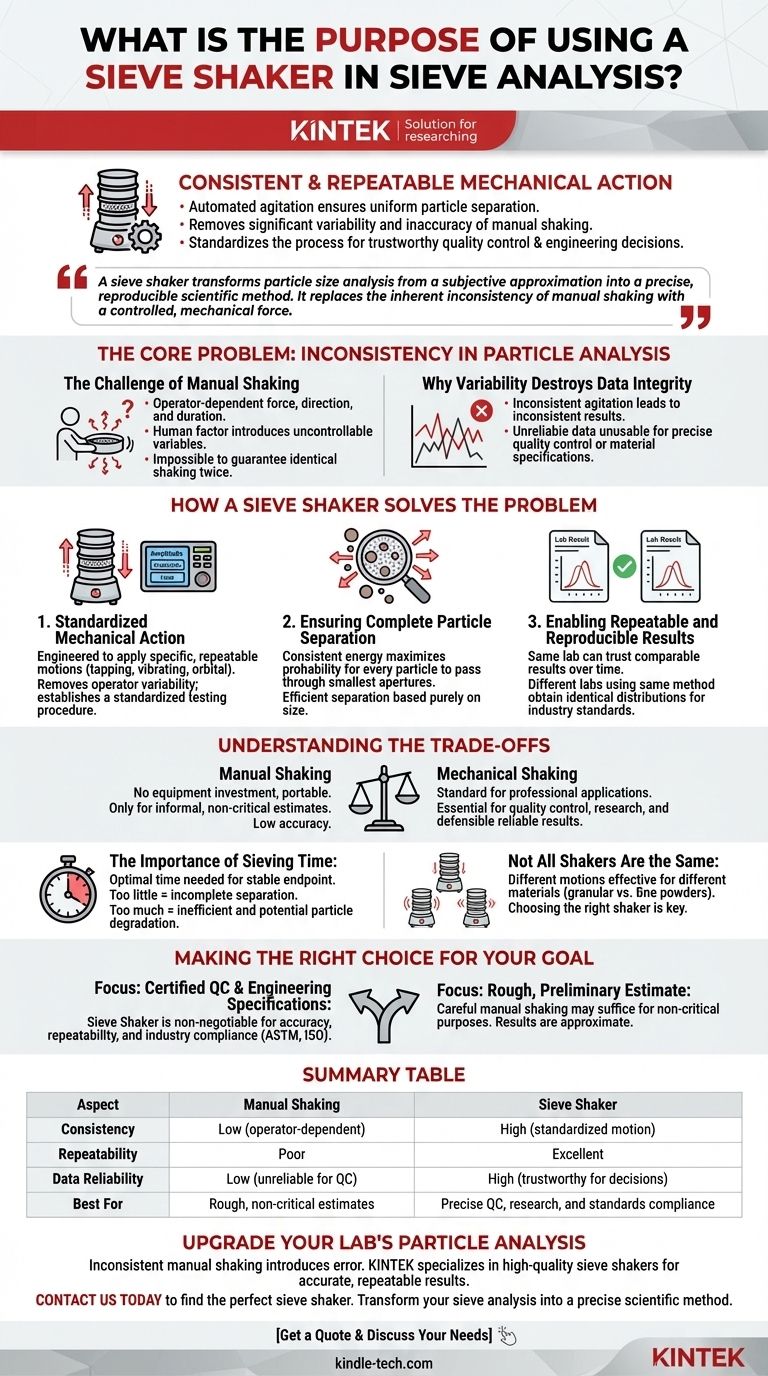

The Core Problem: Inconsistency in Particle Analysis

The Challenge of Manual Shaking

When sieving a material by hand, the results are highly dependent on the operator. The force, direction, and duration of shaking will vary from person to person, and even from test to test with the same person.

This human factor introduces uncontrollable variables into the analysis. There is no way to guarantee that a sample was shaken identically twice.

Why Variability Destroys Data Integrity

Inconsistent agitation leads to inconsistent results. A sample might show a different particle size distribution simply because it was shaken more vigorously or for a longer period.

This makes the data unreliable. For applications like manufacturing quality control or designing concrete mixes, where precise material properties are essential, such data is unusable. The goal is to measure the material, not the effectiveness of the person shaking the sieves.

How a Sieve Shaker Solves the Problem

Standardized Mechanical Action

A sieve shaker is engineered to apply a specific, repeatable motion to a stack of test sieves. Common motions include tapping, vibrating, or a combination of orbital and jarring actions.

By setting parameters like amplitude and time, the shaker ensures that every sample is subjected to the exact same agitation process. This removes operator-dependent variability and establishes a standardized testing procedure.

Ensuring Complete Particle Separation

The consistent energy imparted by a shaker maximizes the probability that every particle will be presented to the sieve apertures multiple times and in multiple orientations.

This allows the particles to find their way through the smallest possible mesh, leading to an efficient and complete separation based purely on their size. The test is typically run until the weight of material passing a sieve is negligible, indicating an "end-point" has been reached.

Enabling Repeatable and Reproducible Results

Because the shaking action is standardized, sieve analysis becomes a repeatable process. The same lab can test samples over time and trust the results are comparable.

Furthermore, it makes the results reproducible. Different labs using the same method and equipment can test the same material and obtain nearly identical particle size distributions. This is the foundation of industry standards and material specification.

Understanding the Trade-offs

Manual Shaking vs. Mechanical Shaking

Manual shaking requires no investment in equipment and can be done anywhere. However, it is only suitable for informal, non-critical estimates where a high degree of accuracy and repeatability is not required.

Mechanical shaking with a sieve shaker is the standard for any professional application. It is essential for quality control, research, and any process where results must be reliable and defensible.

The Importance of Sieving Time

Too little sieving time results in incomplete separation and inaccurate data, as finer particles remain trapped on upper sieves. Too much time is inefficient and can, with some friable materials, cause particle degradation (attrition), which also skews results.

A key part of standardizing a test is determining the optimal sieving time to reach a stable endpoint without damaging the sample.

Not All Shakers Are the Same

Different shaker motions are more effective for different materials. A tapping shaker might be ideal for dense, granular materials, while a vibratory shaker may work better for fine powders that tend to agglomerate. Choosing the right shaker is part of developing a valid test method.

Making the Right Choice for Your Goal

The decision to use a sieve shaker depends entirely on the required reliability of your results.

- If your primary focus is certified quality control or engineering specifications: A sieve shaker is non-negotiable to achieve the required accuracy, repeatability, and compliance with industry standards (like ASTM or ISO).

- If your primary focus is a rough, preliminary estimate for a non-critical purpose: Careful manual shaking may suffice, but you must acknowledge that the results are approximate and not suitable for formal reporting.

Ultimately, employing a sieve shaker is what elevates particle analysis from a simple sorting exercise to a robust and reliable scientific measurement.

Summary Table:

| Aspect | Manual Shaking | Sieve Shaker |

|---|---|---|

| Consistency | Low (operator-dependent) | High (standardized motion) |

| Repeatability | Poor | Excellent |

| Data Reliability | Low (unreliable for QC) | High (trustworthy for decisions) |

| Best For | Rough, non-critical estimates | Precise QC, research, and standards compliance |

Upgrade your lab's particle analysis with precision and reliability.

Inconsistent manual shaking introduces error and makes your data unreliable for critical quality control decisions. KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-quality sieve shakers designed to deliver the accurate, repeatable results your work demands.

Contact us today to find the perfect sieve shaker for your materials and standards. Let our experts help you transform your sieve analysis from an approximation into a precise scientific method.

Get a Quote & Discuss Your Needs

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Single Horizontal Jar Mill

People Also Ask

- How do you calibrate a sieve shaker? Ensure Consistent Particle Size Analysis

- What is the role of crushing and sieving systems in wheat straw pretreatment? Maximize Sugar Yield through Particle Sizing

- What is a sieving shaker? Automate Your Particle Size Analysis for Accurate Results

- What is the purpose of maintaining a constant rotation speed in a laboratory shaker? Optimize Vanadium Slag Extraction

- What role does a laboratory shaker play in the pH stabilization process for geopolymer surfaces? Optimize Ion Exchange

- What are the disadvantages of sieve shaker method? Uncover the Critical Limitations for Accurate Particle Analysis

- What is the function of the crushing and sieving system in zinc ash processing? Enhance Efficiency & Recovery

- What is the working principle of sieve shaker? Achieve Precise Particle Size Analysis