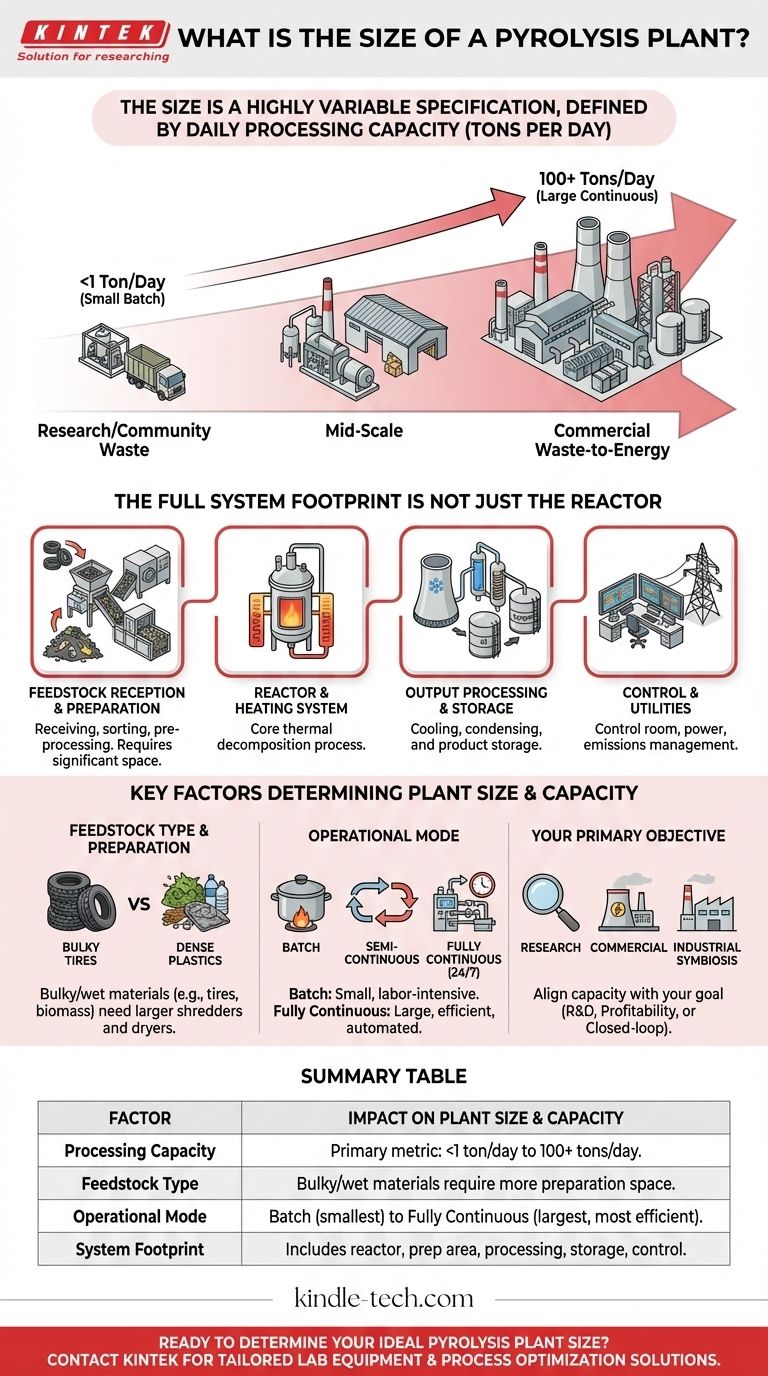

The size of a pyrolysis plant is not a single number but a highly variable specification determined by its function. These systems can range from small, skid-mounted units processing a few hundred kilograms per day to massive industrial facilities handling hundreds of tons of waste daily. The final footprint depends entirely on the required processing capacity, the type of waste feedstock, and the chosen technology.

The "size" of a pyrolysis plant is best understood not by its physical dimensions but by its daily processing capacity, measured in tons. This capacity dictates the scale of the entire system, from waste preparation and storage areas to the pyrolysis reactor and post-processing equipment.

What Defines a Pyrolysis Plant's "Size"?

Many people mistakenly believe the pyrolysis reactor alone defines the plant's size. In reality, the reactor is just one component of a much larger integrated system.

The Core Metric: Capacity (Tons Per Day)

The most critical specification is processing capacity. This refers to the amount of feedstock (like plastic, tires, or biomass) the plant can convert in a 24-hour period.

This metric directly influences the physical dimensions of the reactor, the material handling equipment, and the storage required for both feedstock and output products.

The Full System Footprint

A complete pyrolysis plant includes several essential operational zones that contribute to its overall footprint:

- Feedstock Reception & Preparation: Area for receiving, sorting, and pre-processing waste. This can include shredders, dryers, and balers, which require significant space.

- Reactor & Heating System: This is the core of the plant where the thermal decomposition occurs.

- Output Processing & Storage: Equipment to cool and condense pyrolysis gas into oil, along with tanks to store the final products (oil, syngas, and char).

- Control & Utilities: A control room, power connections, and potentially a system for managing emissions or process water.

Key Factors That Determine Plant Size

The final dimensions and layout of a facility are a direct result of several key design choices. Understanding these factors is crucial for planning a project.

Feedstock Type and Preparation

The type of waste being processed has a major impact. Bulky materials like tires require powerful, large-footprint shredders, whereas denser, pre-sorted plastics might need less preparation space. Wet feedstocks like biomass or municipal solid waste demand large dryers before they can enter the reactor.

Operational Mode: Batch vs. Continuous

Pyrolysis plants operate in one of three modes, each with different space and infrastructure requirements:

- Batch Plants: These are the smallest and simplest. Feedstock is loaded, the process runs, and then the system is cooled and emptied. They are suitable for smaller capacities (e.g., 1-5 tons/day) but are labor-intensive and have a lower throughput.

- Semi-Continuous Plants: These systems can be fed and discharged without a full shutdown, offering better efficiency than batch models. They represent a middle ground in terms of size and complexity.

- Fully Continuous Plants: These are large, industrial-scale facilities designed for 24/7 operation. They require extensive automated feeding and discharge systems, making them the largest and most capital-intensive option, but also the most efficient for high volumes (e.g., 20-100+ tons/day).

Understanding the Trade-offs

Choosing a plant size involves balancing economic viability with logistical reality. Both ends of the scale present unique challenges.

The Challenge of Small-Scale Plants

While small batch plants have a low initial cost and footprint, they often struggle with profitability. Their low throughput and high labor requirements per ton of processed material can make it difficult to achieve a positive return on investment without subsidies or specific niche applications.

The Demands of Large-Scale Plants

Large, continuous plants offer superior economies of scale but demand a massive and consistent supply of feedstock. Securing a stable, long-term source of suitable waste is often the single greatest logistical hurdle. These plants also require significant upfront capital, extensive permitting, and a large physical site.

Matching Plant Size to Your Objective

The right size for a pyrolysis plant is the one that aligns with your primary goal. Use your core objective as the starting point for all technical specifications.

- If your primary focus is research or local community waste: A small-scale batch or skid-mounted system provides operational flexibility with a minimal footprint.

- If your primary focus is commercial-scale waste-to-energy: A large, fully continuous plant is necessary to achieve the efficiency and throughput required for profitability.

- If your primary focus is industrial symbiosis (e.g., a factory processing its own plastic waste): The plant size should be precisely matched to your facility's daily waste output to create a closed-loop system.

Ultimately, defining your operational capacity and feedstock strategy is the first and most critical step in determining the right-sized pyrolysis solution.

Summary Table:

| Factor | Impact on Plant Size & Capacity |

|---|---|

| Processing Capacity | The primary metric. Ranges from <1 ton/day (small batch) to 100+ tons/day (large continuous). |

| Feedstock Type | Bulky/wet materials (tires, biomass) require more preparation space (shredders, dryers). |

| Operational Mode | Batch (smaller, simpler) vs. Semi-Continuous vs. Fully Continuous (largest, most efficient). |

| System Footprint | Includes reactor, preparation area, output processing, storage tanks, and control room. |

Ready to determine the ideal pyrolysis plant size for your operation?

At KINTEK, we specialize in providing tailored lab equipment and consumables for pyrolysis R&D and process optimization. Whether you're in the research phase or scaling up to commercial production, our expertise can help you select the right equipment to match your capacity needs and feedstock type.

Contact our experts today to discuss your project and discover how KINTEK's solutions can enhance your pyrolysis efficiency and profitability.

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Wall Mounted Water Distillation Unit

- Laboratory Hybrid Tissue Grinding Mill

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- Which is the most important disadvantage of biomass pyrolysis? The Problem of Poor-Quality Bio-Oil

- How is pyrolysis sustainable? Turning Waste into Energy and Circular Materials

- What is the history of pyrolysis technology? From Wood Distillation to Modern Waste Valorization

- What are the steps of biomass pyrolysis? Turn Waste into Biochar, Bio-Oil & Biogas

- What are the different forms of biomass conversion? Choose the Right Process for Your Feedstock and Goal

- What is bio-oil from biomass? A Guide to Pyrolysis Oil Production and Uses

- How does particle size affect pyrolysis? Control Your Product Yields with Precision

- Is plastic pyrolysis effective? A Balanced Look at Converting Waste into Resources