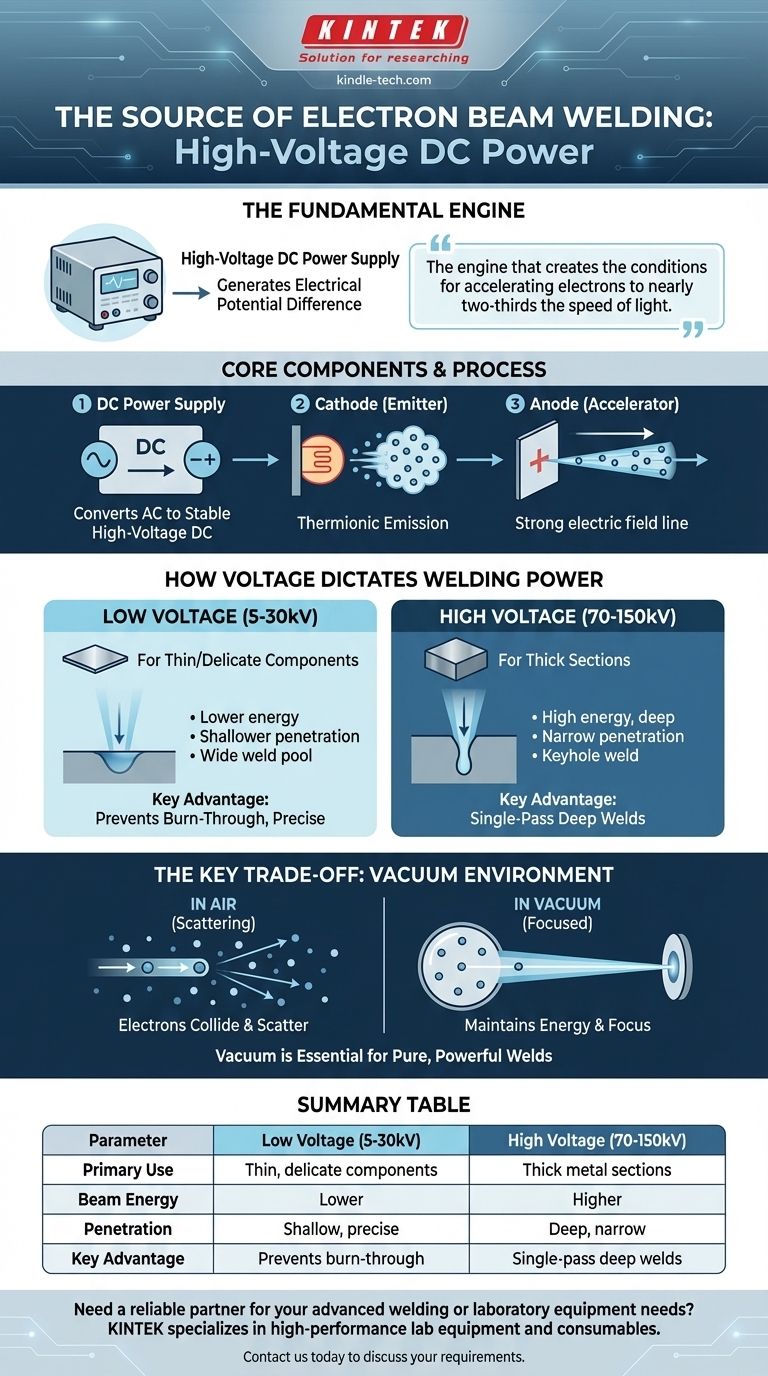

The source of an electron beam weld is a high-voltage direct current (DC) power supply. This specialized power source is responsible for generating a significant electrical potential difference between a cathode (the electron emitter) and an anode (the accelerator), which is the fundamental first step in creating a high-energy beam of electrons for welding.

The power supply is not merely a source of electricity; it is the engine that creates the conditions for accelerating electrons to nearly two-thirds the speed of light, transforming them into a powerful tool for joining materials.

The Core Components of the Power System

To understand the source, you must understand the system it drives. The DC power supply is the heart of a system designed to generate, accelerate, and focus a beam of electrons.

The High-Voltage DC Power Supply

This unit converts standard alternating current (AC) from the grid into the stable, high-voltage direct current (DC) required for the process. Its primary function is to create a powerful and stable electric field.

The Cathode (The Emitter)

The negative terminal of the power supply is connected to a filament, typically made of tungsten, which acts as the cathode. The power supply heats this filament, causing it to release a cloud of free electrons in a process called thermionic emission.

The Anode (The Accelerator)

The positive terminal of the power supply creates a strong positive charge on the anode. This establishes a massive voltage difference between the negative cathode and the positive anode, which violently accelerates the cloud of free electrons toward the anode, forming a coherent beam.

How Voltage Dictates Welding Power

The voltage level generated by the power supply directly controls the kinetic energy of the electrons in the beam. This energy determines the beam's penetration depth and welding capability.

Low Voltage for Thin Materials

For welding thin or delicate components, power sources typically operate in the 5kV to 30kV range. The lower voltage imparts less velocity to the electrons, resulting in a lower-energy beam with shallower penetration, which prevents burning through the material.

High Voltage for Thick Materials

To weld thick sections of metal, power sources must generate much higher voltages, typically between 70kV and 150kV. This extreme voltage accelerates electrons to very high speeds, creating a high-energy beam capable of producing deep, narrow, and high-quality welds.

Understanding the Key Trade-off: Power vs. Environment

The use of a high-voltage electron beam introduces a fundamental operational requirement that defines the entire process.

The Necessity of a Vacuum

An electron beam can only maintain its energy and focus in a vacuum. If fired in open air, the electrons would immediately collide with air molecules, scattering their energy and making welding impossible.

Therefore, the entire process must be conducted inside a vacuum chamber. While this allows for exceptionally pure and powerful welds, it adds significant complexity, cost, and cycle time to the operation compared to other welding methods.

Matching the Source to the Application

The choice of power source voltage is dictated entirely by the material and the joint design.

- If your primary focus is welding thin, delicate components: A lower-voltage system (5-30kV) provides the necessary precision and controlled penetration.

- If your primary focus is joining thick metal sections for structural applications: A high-voltage system (70-150kV) is required to generate the high-energy beam needed for deep, single-pass welds.

Understanding the power source is the key to mastering the unique capabilities of the electron beam welding process.

Summary Table:

| Parameter | Low Voltage (5-30kV) | High Voltage (70-150kV) |

|---|---|---|

| Primary Use | Thin, delicate components | Thick metal sections |

| Beam Energy | Lower | Higher |

| Penetration | Shallow, precise | Deep, narrow |

| Key Advantage | Prevents burn-through | Single-pass deep welds |

Need a reliable partner for your advanced welding or laboratory equipment needs? KINTEK specializes in high-performance lab equipment and consumables, serving industries that require precision and reliability. Whether you're working with advanced materials or need robust solutions for your R&D or production, our expertise can help you achieve superior results. Contact us today to discuss how we can support your specific requirements!

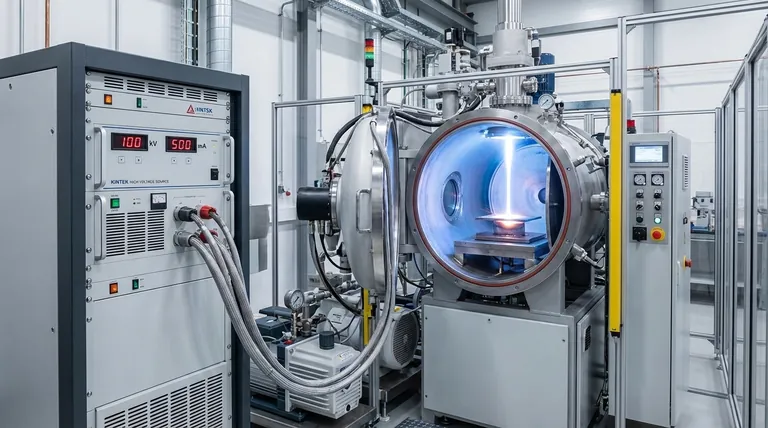

Visual Guide

Related Products

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Vacuum Cold Mounting Machine for Sample Preparation

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why are glove boxes or vacuum equipment indispensable for ZrO2-Li2ZrCl6 preparation? Protect Air-Sensitive Materials

- Why is a vacuum oven necessary for treating SiOx anodes? Ensure Battery Stability and Prevent Copper Oxidation

- What are the benefits of a heat treatment furnace? Achieve Precise Control Over Material Properties

- What is sintering of powder metals? Transform Powder into High-Performance Metal Parts

- What is arc melting? Harnessing Extreme Heat for High-Performance Metals

- What are the methods of heat treatment of steel? Engineer Your Steel's Properties for Any Application

- What is the role of a high-vacuum box furnace for TB8 titanium alloys? Ensure Microstructural Stability and Purity

- What is the core role of Hot Isostatic Pressing (HIP) equipment? Master High-Density Consolidation for Alloys