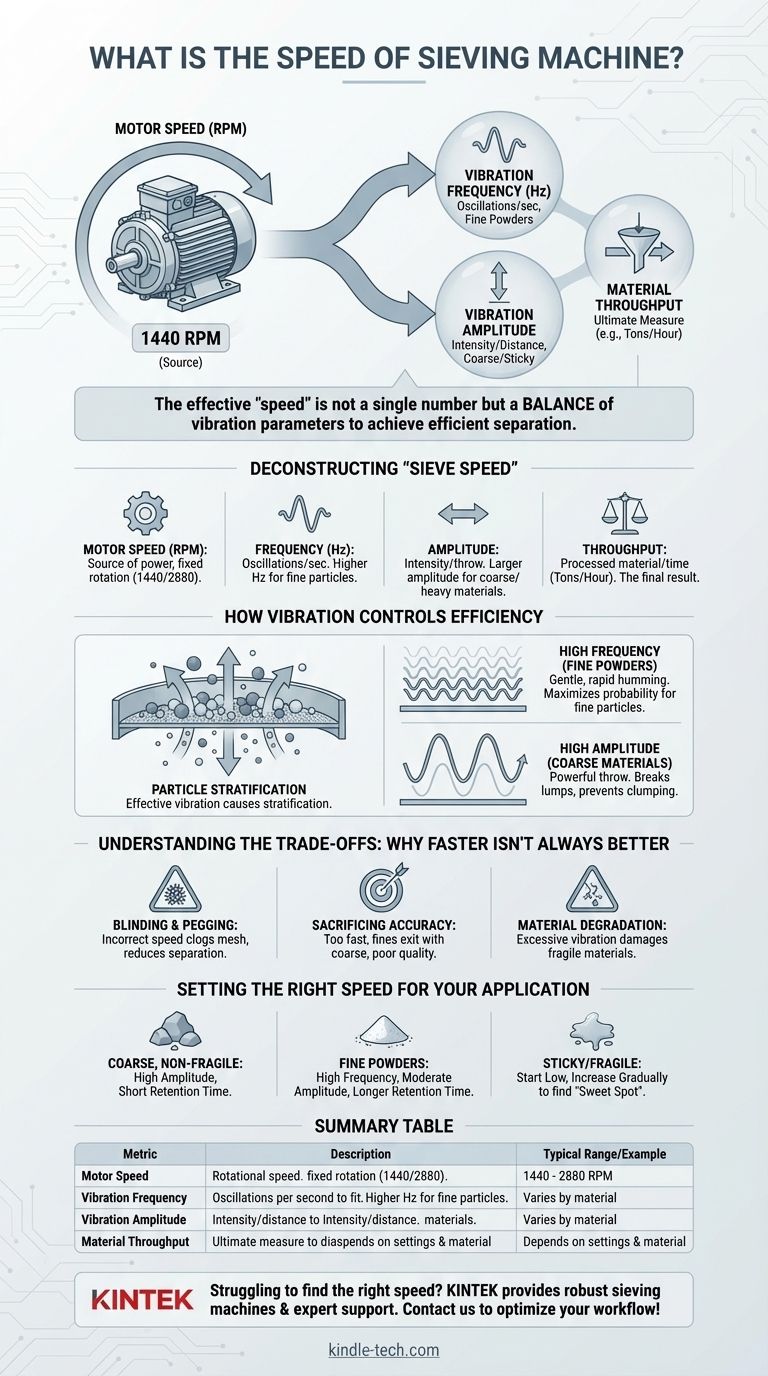

The speed of a sieving machine is not defined by a single number but is a function of several interconnected parameters. The most direct answer is the motor's rotational speed, which is often a standard 1440 revolutions per minute (RPM). However, this motor speed only creates the vibration; the effective "speed" is truly measured by the machine's throughput—the volume of material it can accurately separate over time.

The core challenge is not to find a single "speed" setting, but to balance the machine's vibration characteristics—its frequency and amplitude—to achieve the most efficient and accurate separation for your specific material. Faster is not always better and can often harm your results.

Deconstructing "Sieve Speed": The Key Metrics

To truly understand the speed of a sieving machine, we must break the concept down into its core components. Each one plays a distinct role in the final performance.

Motor Speed (RPM)

The process begins with the electric motor. Most vibratory sieving machines use a standard motor that operates at a fixed rotational speed, typically 1440 or 2880 RPM. This is the source of the machine's power, but it is not the variable you typically adjust.

Vibration Frequency (Hz)

The motor's rotation is converted into vibration. Frequency measures how many times the screen oscillates per second. A higher frequency provides more opportunities for a particle to find an opening in the mesh, which is especially useful for separating very fine powders.

Vibration Amplitude

Amplitude is the intensity of the vibration—the distance the screen travels during each oscillation. A larger amplitude imparts more energy, which is necessary to move heavier, coarser, or stickier materials across the screen and prevent clumping.

Material Throughput (Tons/Hour)

This is the ultimate measure of "speed" in an industrial context. It quantifies how much material is successfully processed per unit of time (e.g., kilograms per hour or tons per hour). Throughput is the result of correctly setting the frequency, amplitude, and material feed rate.

How Vibration Parameters Control Sieving Efficiency

The goal of sieving is to separate particles by size. The machine's settings are tuned to optimize this physical process.

The Goal: Particle Stratification

Effective vibration causes a phenomenon called stratification. The motion agitates the material bed, causing larger particles to rise to the top while smaller particles sink toward the screen mesh, where they have a chance to pass through.

The Role of Frequency for Fine Powders

High frequency with lower amplitude creates a gentle, rapid "humming" motion. This is ideal for fine, dry powders. The high number of small vibrations maximizes the probability that fine particles will encounter an aperture in the mesh before the material bed moves on.

The Role of Amplitude for Coarse Materials

High amplitude creates a more aggressive, longer "throw." This is crucial for heavy, wet, or coarse materials. The powerful motion breaks up lumps, keeps sticky material from adhering to the screen, and effectively throws larger particles forward to clear the screen for more material.

Adjusting Retention Time

Some advanced sieves allow for the adjustment of the vibration angle. This controls how quickly material travels from the center to the periphery of the screen. A longer retention time (slower travel) increases accuracy but reduces throughput, while a shorter time does the opposite.

Understanding the Trade-offs: Why Faster Isn't Always Better

Maximizing the speed settings is a common mistake that almost always leads to poor results. The key is finding an optimal balance.

The Risk of Blinding and Pegging

If the vibration is incorrect for the particle size, screen blinding can occur. Blinding is when fine, sticky particles clog the mesh openings. Pegging happens when near-size particles get wedged into the apertures. Both scenarios dramatically reduce or halt the separation process. An overly aggressive speed can force particles into the mesh, making this worse.

Sacrificing Accuracy for Throughput

Moving material across the screen too quickly gives fine particles insufficient time to stratify and pass through the mesh. The result is that a significant portion of your "fines" will exit with the "coarse" material, leading to poor separation quality and wasted product.

Material Degradation

For fragile or friable materials, such as crystals, grains, or certain chemical pellets, excessive vibration can be destructive. The high-energy impacts can break down the particles, creating more "fines" than were originally present and altering the final product characteristics.

Setting the Right Speed for Your Application

The ideal machine speed is entirely dependent on your material properties and your primary operational goal. Always start with the manufacturer's recommended settings for your material and adjust methodically from there.

- If your primary focus is high throughput of coarse, non-fragile materials: Prioritize a higher amplitude and a shorter retention time to move material across the screen quickly and efficiently.

- If your primary focus is high-accuracy separation of fine powders: Focus on a higher frequency with a moderate amplitude and a longer retention time to maximize the chances for every fine particle to pass through the mesh.

- If your primary focus is processing sticky or fragile materials: Begin with lower amplitude and frequency settings, then gradually increase them to find the "sweet spot" that ensures flow without causing material damage or screen blinding.

Ultimately, optimal sieving speed is found through methodical testing and adjustment, not by simply setting a dial to maximum.

Summary Table:

| Key Metric | Description | Typical Range/Example |

|---|---|---|

| Motor Speed (RPM) | Rotational speed of the motor, the source of vibration. | 1440 - 2880 RPM |

| Vibration Frequency (Hz) | Oscillations per second; critical for fine powder separation. | Varies by material |

| Vibration Amplitude | Intensity/distance of vibration; crucial for coarse/sticky materials. | Varies by material |

| Material Throughput | The ultimate measure of speed (e.g., tons/hour). | Depends on settings & material |

Struggling to find the right speed for your sieving process? The optimal balance of vibration frequency and amplitude is key to achieving high throughput and accurate particle separation without screen blinding or material degradation. KINTEK specializes in lab equipment and consumables, providing robust sieving machines and expert support to help you optimize your workflow for any material—from fine powders to coarse aggregates. Let our experts help you maximize your efficiency. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

- Laboratory Test Sieves and Sieving Machines

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- What is the role of a mechanical sieve shaker and standard sieve sets in the grading analysis of crushed glass for concrete? Precision Sieving for Quality Aggregates

- What are the limitations of sieve shaker? Avoid Costly Errors in Particle Size Analysis

- How do laboratory shakers ensure accuracy in adsorption studies? Optimize Your Kinetics and Isotherm Data Today

- What is the critical function of high-precision sieving for aluminum powders? Ensure Uniform Composite Integrity

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What are the advantages of a sieving machine? Achieve Precise Particle Analysis for Quality Control

- What role does a laboratory shaker play in the in-situ synthesis of Se/PPS fabrics? Achieve Deep Fiber Functionalization

- What is the role of a rotary shaker in bacterial attachment experiments? Isolate True Biological Adhesion