At its core, a standard test sieve is a precision tool used to measure particle size distribution. It functions by separating a granular material sample into different size fractions. This process, known as a sieve analysis, is a fundamental quality control and analytical procedure in industries ranging from pharmaceuticals and food production to mining and agriculture.

The primary function of a test sieve isn't just to separate particles, but to provide quantitative data on the size distribution within a sample, which is a critical quality control metric in countless industrial processes.

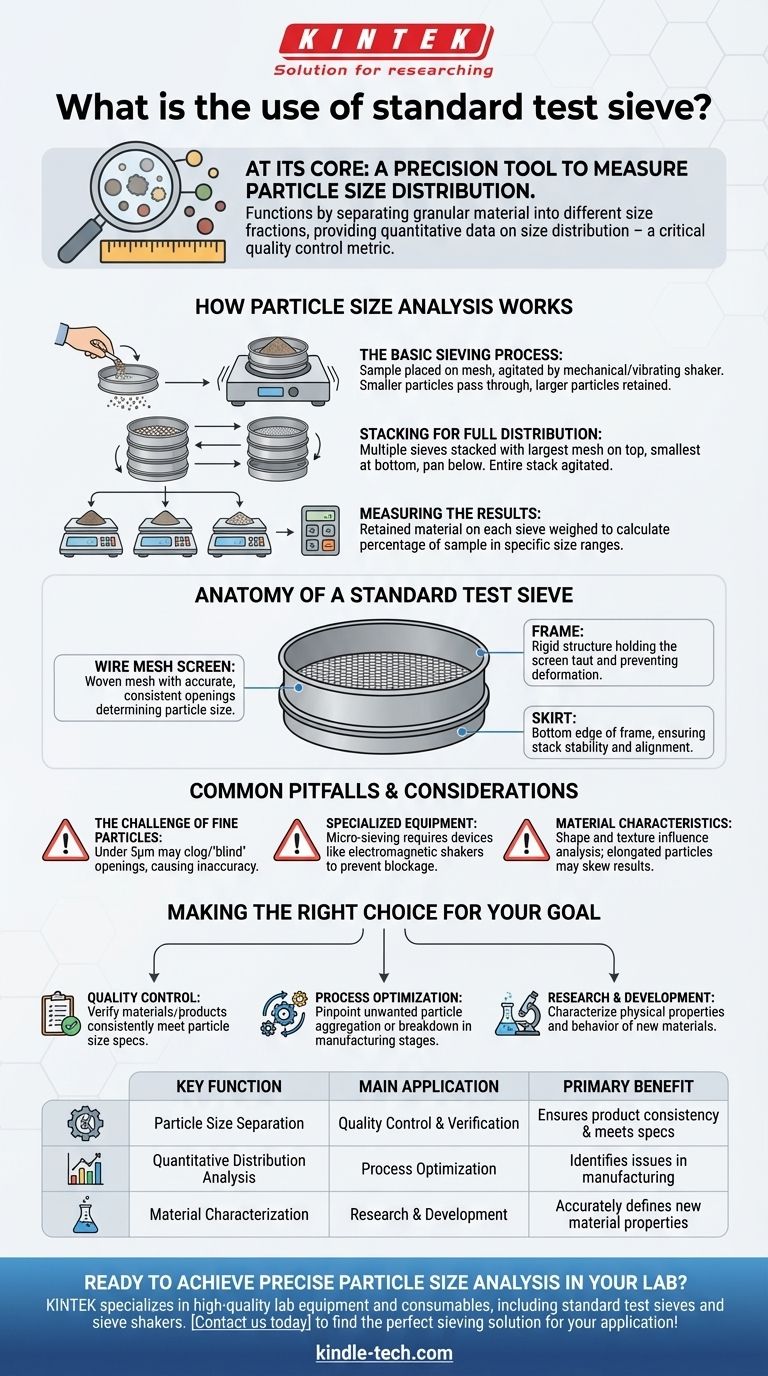

How Particle Size Analysis Works

The goal of using a test sieve is to determine the proportion of particles of different sizes within a given sample. This is achieved through a straightforward and reliable mechanical process.

The Basic Sieving Process

A weighed sample of the material is placed onto the mesh screen of a single sieve. This sieve is then agitated, typically by a mechanical or vibrating sieve shaker.

This agitation causes smaller particles to pass through the mesh openings while retaining larger particles on the screen's surface.

Stacking for a Full Distribution

For a complete analysis, multiple sieves are stacked together. This stack is arranged with the sieve having the largest mesh openings at the top, followed by progressively finer sieves, and a solid pan at the bottom to collect the smallest particles.

When the entire stack is agitated, the sample is sorted across the different levels. Each sieve captures particles larger than its own mesh size but smaller than the mesh size of the sieve above it.

Measuring the Results

After the shaking is complete, the material retained on each individual sieve is weighed. This data is then used to calculate the percentage of the sample that falls within each specific size range, creating a clear picture of the overall particle size distribution.

Anatomy of a Standard Test Sieve

A test sieve's effectiveness comes from its simple but precise construction, which consists of three key components.

The Wire Mesh Screen

This is the most critical part of the sieve. The wire cloth is a woven mesh with highly accurate and consistent openings that determine the size of particles being separated.

The Frame

The frame provides the rigid structure that holds the wire mesh screen, keeping it taut and preventing it from deforming during use.

The Skirt

The skirt is the bottom edge of the frame, designed to fit snugly into the top of the next sieve in a stack. This design ensures the stack remains stable and aligned during vigorous shaking.

Common Pitfalls and Considerations

While sieving is a reliable method, its accuracy depends on understanding its limitations and the nature of the material being tested.

The Challenge of Fine Particles

Extremely fine particles, especially those under 5 micrometers (μm), can cause issues. They may clog or "blind" the mesh openings, preventing other particles from passing through and leading to inaccurate results.

Specialized Equipment

For these "micro" sieving applications, specialized equipment like an electromagnetic sieve shaker is often used. These devices provide a different type of agitation that helps prevent the fine mesh from getting blocked by certain solid particles.

Material Characteristics

The shape and texture of the particles can influence the analysis. Elongated or irregularly shaped particles may not pass through the mesh as easily as spherical ones, which can skew the final distribution data.

Making the Right Choice for Your Goal

The application of sieve analysis is directly tied to your specific objective.

- If your primary focus is quality control: Use a certified stack of sieves to verify that your raw materials or finished products consistently meet required particle size specifications.

- If your primary focus is process optimization: Analyze samples from different stages of a manufacturing process to pinpoint where unwanted particle aggregation or breakdown is happening.

- If your primary focus is research and development: Employ a wide range of sieve sizes to accurately characterize the physical properties and behavior of a new material.

Ultimately, mastering the use of test sieves provides the precise data needed to control and improve your material-based processes.

Summary Table:

| Key Function | Main Application | Primary Benefit |

|---|---|---|

| Particle Size Separation | Quality Control & Verification | Ensures product consistency and meets specifications |

| Quantitative Distribution Analysis | Process Optimization | Identifies issues in manufacturing stages |

| Material Characterization | Research & Development | Accurately defines physical properties of new materials |

Ready to achieve precise particle size analysis in your lab? KINTEK specializes in high-quality lab equipment and consumables, including a full range of standard test sieves and sieve shakers. Our products are designed to deliver the accuracy and reliability your quality control and R&D processes demand. Contact us today to find the perfect sieving solution for your specific application and enhance your material analysis capabilities!

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Small Lab Rubber Calendering Machine

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy

- What are the different types of sieving machines? Choose the Right Motion for Your Material

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What is powder sieving? A Guide to Accurate Particle Size Separation

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis