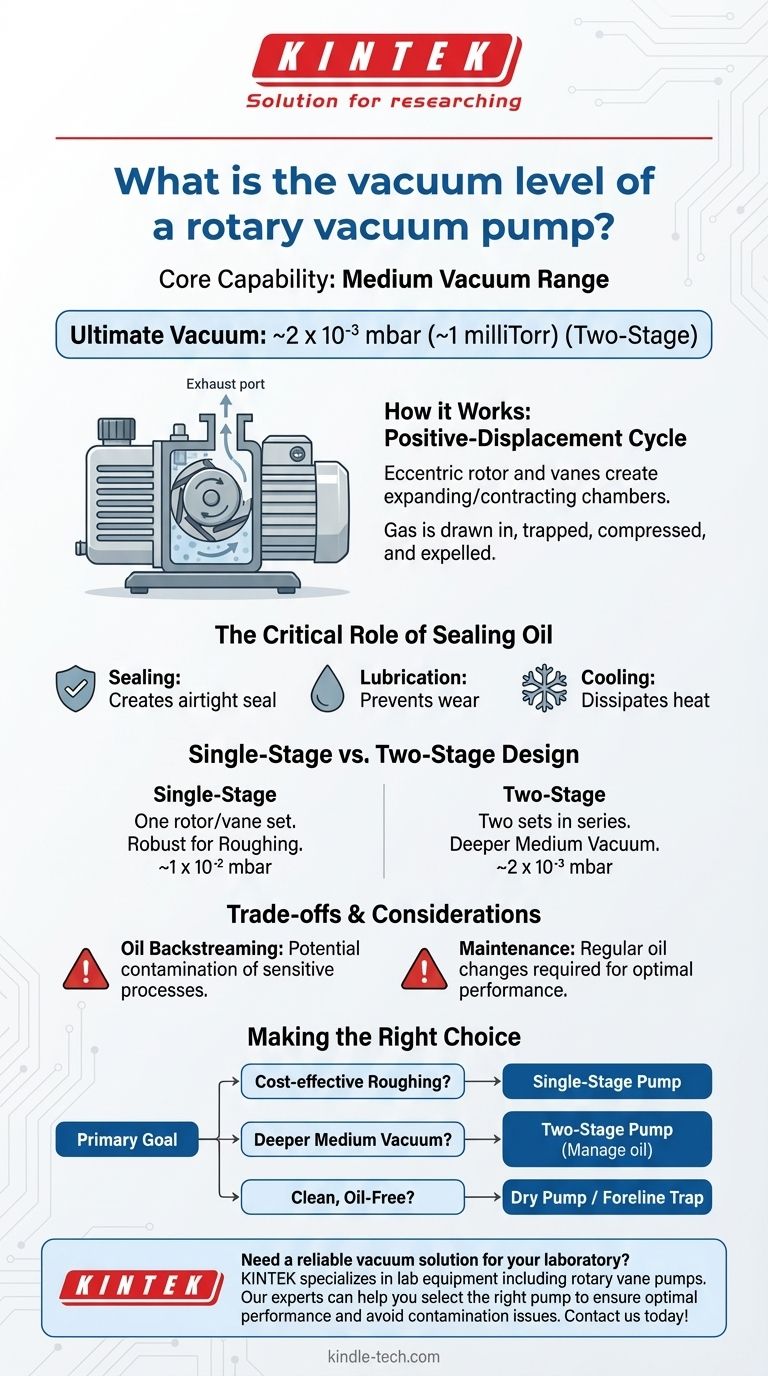

At its core, an oil-sealed rotary vane vacuum pump can typically achieve an ultimate vacuum level as low as 2 x 10⁻³ mbar, which is approximately 1 milliTorr. This capability places it firmly in the medium vacuum range, making it highly effective for a wide variety of industrial and laboratory applications. The specific level depends on whether it is a single-stage or two-stage design.

The vacuum level of a rotary vane pump is a direct result of its oil-sealed, positive-displacement mechanism. While this design is robust and efficient for creating a medium vacuum, understanding the role and limitations of the oil is the most critical factor for determining if this pump is right for your application.

How a Rotary Vane Pump Creates a Vacuum

A rotary vane pump operates on a simple and effective mechanical principle to move gas molecules out of a sealed volume.

The Core Mechanical Principle

The pump consists of a cylindrical housing (stator) with a rotor mounted eccentrically inside it. This rotor contains slots with sliding vanes that are pushed outwards by springs or centrifugal force.

As the rotor turns, the vanes continuously slide along the inner wall of the housing. This creates expanding and contracting chambers between the vanes, the rotor, and the housing wall.

The Positive-Displacement Cycle

Gas from the inlet port is drawn into a chamber as its volume expands. As the rotor continues to turn, this chamber is sealed off from the inlet.

The captured gas is then compressed as the chamber volume decreases due to the eccentric placement of the rotor. Finally, the compressed gas is forced out through the exhaust port.

The Critical Role of Sealing Oil

The "ultimate vacuum" is not just a function of the mechanics; it is heavily dependent on the specially formulated oil used within the pump.

Creating the Perfect Seal

The low vapor pressure oil fills the microscopic gaps between the tips of the vanes and the housing wall. This creates an airtight seal that is essential for preventing leaks and achieving a deep vacuum.

Lubrication and Cooling

Beyond sealing, the oil serves two other vital functions. It lubricates all moving parts to prevent wear and ensures smooth operation.

It also helps dissipate the heat generated during the gas compression cycle, preventing the pump from overheating.

Factors That Determine Ultimate Vacuum

Not all rotary vane pumps are created equal. The final vacuum level is primarily determined by the pump's configuration.

Single-Stage Pumps

A single-stage pump has one set of rotor and vanes. It compresses the gas from inlet pressure down to atmospheric pressure in a single rotation, making it a robust and common choice for roughing applications.

Two-Stage Pumps

A two-stage pump is essentially two single-stage pumps connected in series within the same housing. The exhaust of the first stage becomes the inlet for the second stage.

This design allows the second stage to begin compressing gas that is already at a reduced pressure. This significantly improves the ultimate vacuum level the pump can achieve, often by an order of magnitude or more.

Understanding the Trade-offs

While effective, the oil-sealed design has inherent limitations that are critical to consider for any sensitive application.

Oil Backstreaming and Contamination

The biggest drawback is the potential for oil vapor to travel backward from the pump into the vacuum chamber. This phenomenon, known as backstreaming, can contaminate sensitive samples or processes.

Maintenance Requirements

The oil in the pump degrades over time and must be changed periodically. Failure to do so will result in poor vacuum performance and potential damage to the pump.

Suitability as a "Roughing" Pump

Because of these limitations, rotary vane pumps are most often used as roughing pumps or backing pumps. They perform the initial work of bringing a system from atmospheric pressure down to the medium vacuum range.

From there, a different type of high-vacuum pump (like a turbomolecular or diffusion pump), which cannot operate at atmospheric pressure, takes over to achieve a much deeper vacuum.

Making the Right Choice for Your Application

Selecting the right vacuum technology begins with understanding your ultimate goal.

- If your primary focus is cost-effective roughing: A single-stage rotary vane pump is an excellent workhorse for bringing a system to a medium vacuum level or for backing a high-vacuum pump.

- If your primary focus is achieving a deeper medium vacuum: A two-stage rotary vane pump is the superior choice, but you must still account for the oil in your system.

- If your primary focus is a clean, oil-free environment: You must either use a foreline trap to mitigate oil backstreaming or choose an entirely different "dry" pump technology, such as a diaphragm or scroll pump.

Understanding this pump's mechanism and its fundamental reliance on oil is the key to deploying it successfully in your work.

Summary Table:

| Feature | Single-Stage Pump | Two-Stage Pump |

|---|---|---|

| Ultimate Vacuum | ~1 x 10⁻² mbar | ~2 x 10⁻³ mbar (1 milliTorr) |

| Primary Use | Roughing applications | Deeper medium vacuum |

| Oil Dependency | High (sealing, lubrication) | High (sealing, lubrication) |

| Key Consideration | Cost-effective for initial evacuation | Better ultimate vacuum, but potential for oil contamination |

Need a reliable vacuum solution for your laboratory? KINTEK specializes in lab equipment and consumables, including rotary vane pumps for efficient roughing and medium vacuum applications. Our experts can help you select the right pump to ensure optimal performance and avoid contamination issues. Contact us today to discuss your specific vacuum needs and enhance your lab's capabilities!

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What are the advantages of rotary vane pumps? Unlock Cost-Effective, High-Performance Vacuum

- Why is a gas ballast valve necessary on a rotary vane vacuum pump? Protect Your Oil and Extend Pump Life

- What are the limitations of rotary vane pumps? Understanding Oil Dependence and Gas Compatibility

- What is a Rotary Vane Vacuum Pump? Efficiency and Performance for Laboratory Vacuum Systems

- What are the fundamental differences between low-cost and high-end industrial rotary vane vacuum pumps? | KINTEK