In essence, thin film optical coating technology is the process of depositing microscopic layers of specific materials onto an optical surface, like a lens or mirror. These layers, often thinner than a wavelength of light, are precisely engineered to manipulate how light is reflected, transmitted, or absorbed, fundamentally changing the optical component's performance.

The critical takeaway is that optical coatings are not merely a protective finish. They are an active, engineered component of the optical system itself, designed to control the physics of light waves to achieve a specific outcome, such as eliminating glare or creating a perfect mirror.

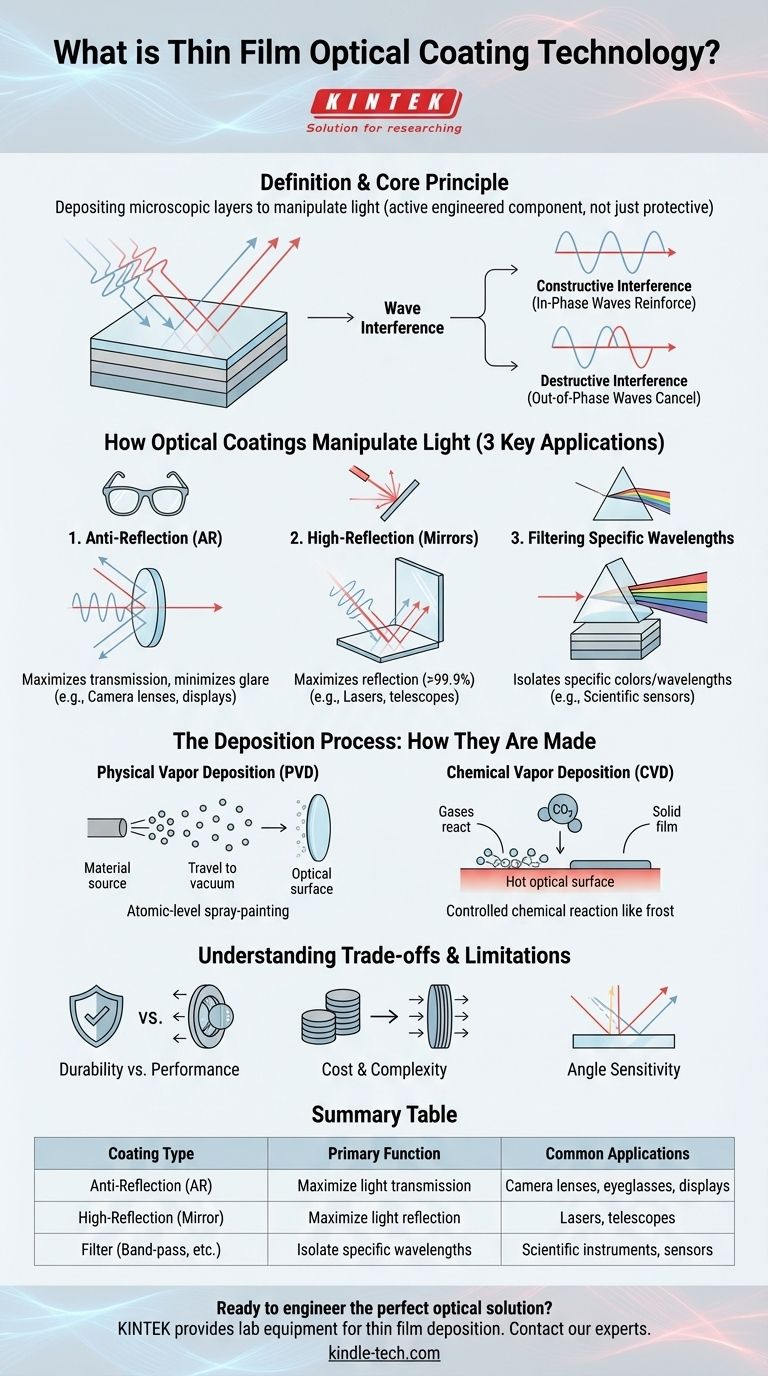

How Optical Coatings Manipulate Light

To understand the value of thin film coatings, you must first understand that they work by exploiting the wave-like nature of light. The core principle at play is wave interference.

The Principle of Wave Interference

When light waves reflect off the different layers of a coating, they can either reinforce each other (constructive interference) or cancel each other out (destructive interference).

By controlling the thickness and material of each layer, engineers can precisely dictate which light waves interfere constructively or destructively.

Enhancing Transmission (Anti-Reflection)

The most common application is an anti-reflection (AR) coating, seen on everything from eyeglasses to high-end camera lenses.

These coatings are designed so that light waves reflecting from the film's surface are perfectly out of phase with the waves reflecting from the lens's surface. This causes destructive interference, canceling out the reflection and allowing more light to pass through the lens.

Maximizing Reflection (Mirrors)

Conversely, coatings can be designed to create highly efficient mirrors, common in lasers and telescopes.

In this case, layers are structured so that light waves reflecting from each interface are perfectly in phase. This constructive interference amplifies the reflection, creating a surface that can reflect over 99.9% of specific light wavelengths.

Filtering Specific Wavelengths

Coatings can also act as precise filters. By stacking layers, it's possible to create a coating that transmits a very narrow band of colors (wavelengths) while reflecting all others.

This is fundamental technology for scientific instruments, sensors, and projection systems that need to isolate specific parts of the light spectrum.

The Deposition Process: How Thin Films Are Made

Applying these ultra-thin, uniform layers requires highly controlled processes inside a vacuum chamber. The two dominant methods are Physical Vapor Deposition and Chemical Vapor Deposition.

Physical Vapor Deposition (PVD)

PVD is a mechanical process. A source material (like titanium dioxide or silicon dioxide) is vaporized in a vacuum, and its atoms or molecules travel in a straight line to physically deposit onto the target optical surface.

Think of it as an atomic-level spray-painting process, where individual atoms form a perfectly even layer.

Chemical Vapor Deposition (CVD)

CVD is a chemical process. Specific gases are introduced into a chamber containing the optic. These gases react on the hot surface of the optic, forming the desired solid film as a byproduct of the chemical reaction.

This is analogous to how frost forms on a cold window, but instead of water vapor condensing, it is a controlled chemical reaction forming a dense, durable film.

Understanding the Trade-offs and Limitations

While powerful, thin film coating technology is not without its constraints. Acknowledging these is crucial for making informed engineering decisions.

Durability vs. Performance

Often, the most optically efficient materials are not the most durable. An extremely complex, high-performance anti-reflection coating might be softer and more susceptible to scratching than a simpler, more robust coating.

Cost and Complexity

The cost of a coating increases dramatically with the number of layers and the precision required. A simple single-layer AR coating is inexpensive, while a 100-layer filter for a specialized laser system can be exceptionally costly.

Angle Sensitivity

The performance of many coatings, especially complex filters, can change depending on the angle at which light strikes the surface. A filter that works perfectly for light hitting head-on may perform differently for light coming in at a 45-degree angle.

Making the Right Choice for Your Application

Selecting the right coating technology begins with defining your primary goal.

- If your primary focus is maximum clarity (e.g., camera lenses, displays): You need a multi-layer broadband anti-reflection (AR) coating to maximize light transmission and minimize glare.

- If your primary focus is high reflectivity (e.g., laser mirrors, telescopes): You need a dielectric or enhanced metallic mirror coating designed for constructive interference at specific wavelengths.

- If your primary focus is precise light separation (e.g., scientific sensors, machine vision): You require a specialized band-pass, long-pass, or short-pass filter coating to isolate the exact wavelengths of interest.

Ultimately, understanding these core principles empowers you to specify not just an optic, but a complete optical solution engineered for optimal performance.

Summary Table:

| Coating Type | Primary Function | Common Applications |

|---|---|---|

| Anti-Reflection (AR) | Maximize light transmission | Camera lenses, eyeglasses, displays |

| High-Reflection (Mirror) | Maximize light reflection | Lasers, telescopes |

| Filter (Band-pass, etc.) | Isolate specific wavelengths | Scientific instruments, sensors |

Ready to engineer the perfect optical solution for your application? The right coating is critical for performance. KINTEK specializes in providing the lab equipment and consumables needed for advanced thin film deposition. Contact our experts today to discuss how we can support your laboratory's specific optical coating challenges and help you achieve superior results.

Visual Guide

Related Products

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are sputtering systems used for? A Guide to Advanced Thin-Film Deposition

- What is sputter coating used for? Achieve Superior Thin Films for Electronics, Optics, and Tools

- How is deposition time calculated? Mastering the Clock for Strategic Legal Advantage

- Can I solder copper to copper without flux? The Critical Role of Flux for a Strong Bond

- How thick is the sputter coating for SEM? Achieve Optimal Imaging & Analysis