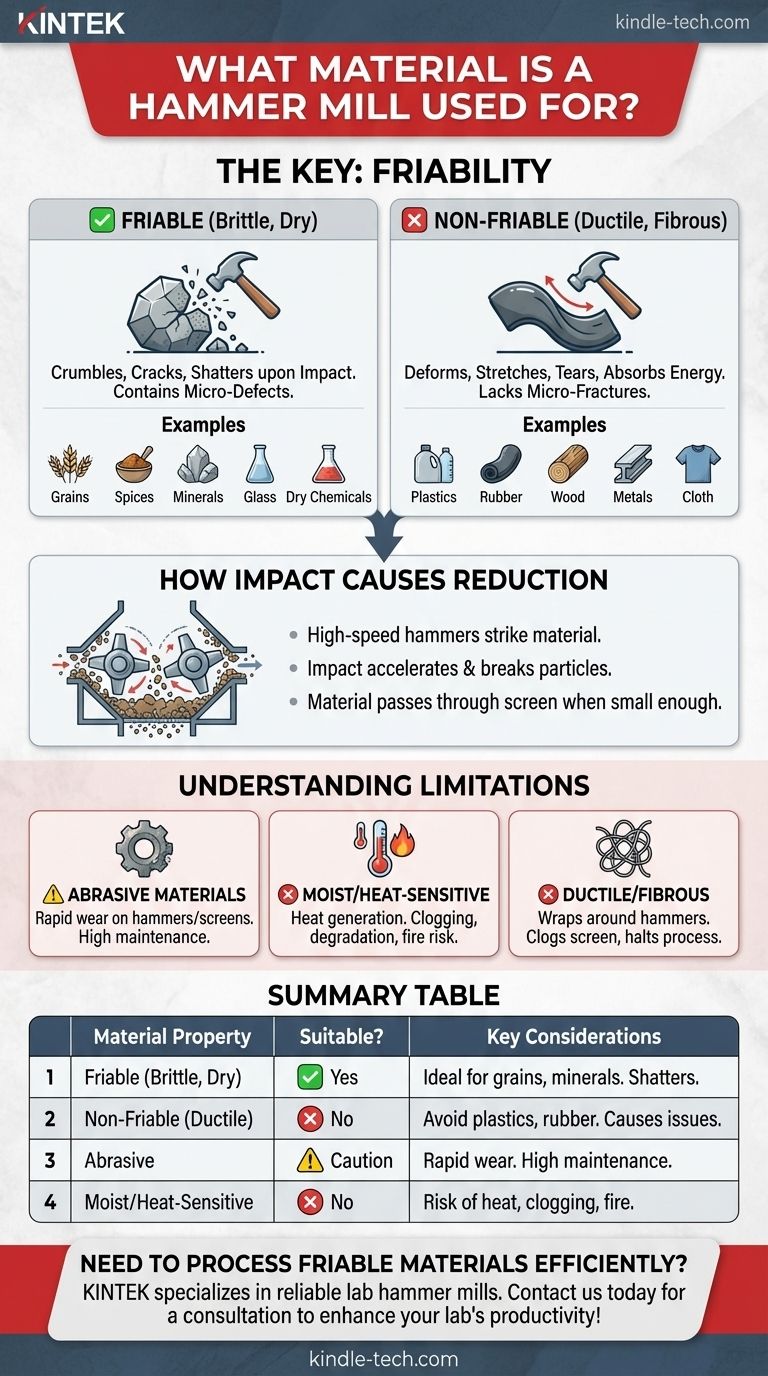

In short, a hammer mill is designed to process friable materials. These are materials that are brittle, dry, or crystalline and will easily crumble, crack, or shatter into a granular or powder consistency when struck with force.

The effectiveness of a hammer mill depends less on the specific material and more on a single physical property: friability. If a material shatters under impact, a hammer mill will likely work; if it deforms, stretches, or tears, it will not.

What Defines a Suitable Material?

A hammer mill is fundamentally a high-impact device. Its entire operation is based on the principle of striking material with hardened steel hammers at very high speeds, causing it to break apart upon impact.

The Critical Role of Friability

A friable material is one that has a tendency to be reduced to smaller particles when subjected to pressure or impact.

These materials contain microscopic defects, fractures, or gaps. When the hammer strikes, energy is transferred into the material, and these defects become points of failure, allowing cracks to propagate rapidly and cause the material to shatter.

How Impact Causes Size Reduction

The process is straightforward. Material is fed into the mill's chamber, where rotating hammers strike it repeatedly. This impact accelerates the material, causing it to collide with the chamber walls or other particles, breaking it down further until it is small enough to pass through a screen.

Why Non-Friable Materials Fail

Conversely, non-friable or ductile materials are unsuitable. These materials lack the internal micro-fractures needed for shattering.

When struck by a hammer, they tend to absorb the energy and deform, smear, or melt rather than break. Trying to process materials like tough plastics, rubber, or metal hard drives will be ineffective and can damage the mill.

Understanding the Limitations

While versatile for the right materials, a hammer mill has clear operational boundaries. Forcing an unsuitable material can lead to inefficiency, equipment damage, and safety hazards.

The Problem with Abrasive Materials

Highly abrasive materials, even if friable, will cause extremely rapid wear on the hammers, screens, and internal chamber liners. This leads to high maintenance costs and significant downtime.

The Risk of Heat Generation

Fibrous or moist materials can generate significant heat from friction. This can degrade the material itself, create a sticky buildup that clogs the screen, or, in the worst case, pose a fire or explosion risk with combustible dusts.

Inefficiency with Ductile or Fibrous Content

Materials that stretch or tear, like cloth or soft plastics, will not shatter. They will often wrap around the hammers, clog the screen, and bring the entire process to a halt without achieving any meaningful size reduction.

Matching the Mill to Your Material

Selecting the right equipment begins with a clear understanding of your input material's physical properties.

- If your primary focus is reducing dry, brittle materials (e.g., grains, spices, minerals, glass, dry chemicals): A hammer mill is an efficient and cost-effective solution for creating a consistent powder or granular product.

- If your primary focus is processing tough, elastic, or fibrous materials (e.g., plastics, rubber, wood, metal): You must consider alternative equipment like a shredder, granulator, or knife mill designed for shearing and cutting.

- If you are unsure of your material's properties: Always test a small sample before committing to a full production run to confirm its friability and avoid costly equipment damage.

Ultimately, aligning the material's characteristics with the machine's mechanism is the key to successful size reduction.

Summary Table:

| Material Property | Suitable for Hammer Mill? | Key Considerations |

|---|---|---|

| Friable (Brittle, Dry) | ✅ Yes | Ideal for grains, spices, minerals, glass, dry chemicals. Shatters upon impact. |

| Non-Friable (Ductile, Fibrous) | ❌ No | Avoid plastics, rubber, cloth. Causes clogging, wear, and inefficiency. |

| Abrasive | ⚠️ Use with Caution | Causes rapid wear on hammers and screens; high maintenance required. |

| Moist or Heat-Sensitive | ❌ No | Risk of heat buildup, degradation, or fire hazard. |

Need to process friable materials efficiently? KINTEK specializes in lab equipment and consumables, providing reliable hammer mills designed for your specific laboratory needs. Our experts can help you select the right mill to achieve consistent particle size reduction, improve your workflow, and avoid costly equipment damage. Contact us today for a consultation and see how we can enhance your lab's productivity!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis